Preparation method of double-shell phosphonyl modified silica magnetic microsphere for extracting uranium from brine

A technology of silica and magnetic microspheres, which is applied in the preparation of microspheres, chemical instruments and methods, microcapsule preparations, etc., can solve the problems of easy dissolution of magnetic substances, and achieve easy magnetic separation, high adsorption capacity, and fast adsorption rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

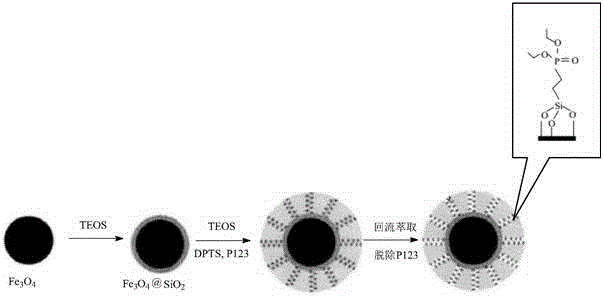

[0024] (1) Preparation of monolayer-coated silica magnetic microspheres (Fe 3 o 4 @SiO 2 )

[0025] 0.1g nano Fe 3 o 4 Add it to 50mL of absolute ethanol, 25mL of deionized water, and 1.5mL of ammonia-water mixture, and disperse evenly by ultrasonic. Then add 0.1g tetraethyl orthosilicate, microwave heating and stirring reaction at 80°C for 5-10h, after centrifugation to obtain solid phase product, the solid phase product is fully washed with deionized water, dried at 60°C to obtain silica magnetic Microspheres.

[0026] (2) Preparation of double-shell phosphono-modified magnetic silica microspheres

[0027] In 60mL absolute ethanol, 80mL deionized water, 1.5mL ammonia water and 1.5mL porogenic template agent (polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer, P123) mixed solution Add 0.2g Fe 3 o 4 @SiO 2 , ultrasonically dispersed for 30 minutes, and then added 0.2 g of tetraethyl orthosilicate (TEOS) and 0.01 g of phosphono functionalizat...

Embodiment 2

[0030] Preparation of double-shell phosphono-modified magnetic silica microspheres

[0031]In 60mL absolute ethanol, 80mL deionized water, 1.5mL ammonia water and 1.5mL porogenic template agent (polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer, P123) mixed solution Add 0.2g Fe 3 o 4 @SiO 2 , Ultrasonic dispersion for 30min. Then add 0.2 g of tetraethyl orthosilicate (TEOS) and 0.02 g of phosphono functionalization reagent (diethylphosphonotriethoxysilane, DPTS) according to 10% of the mass ratio of DPTS / TEOS, and place the resulting mixture in the reaction kettle , stirred at 40°C for about 1h, then heated to 80°C for microwave hydrothermal treatment for 6h, magnetically separated to obtain a solid product and washed thoroughly, the washed product was redispersed in 100mL acidic ethanol solution, and refluxed at 60°C for 12h to remove Templating agent (P123). The obtained product is magnetically separated, fully washed with deionized water and ...

Embodiment 3

[0035] Preparation of double-shell phosphono-modified magnetic silica microspheres

[0036] In 60mL absolute ethanol, 80mL deionized water, 1.5mL ammonia water and 1.5mL porogenic template agent (polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer, P123) mixed solution Add 0.2g Fe 3 o 4 @SiO 2 , Ultrasonic dispersion for 30min. Then add 0.2 g of tetraethyl orthosilicate (TEOS) and 0.03 g of a phosphono functionalization reagent (diethylphosphonotriethoxysilane, DPTS) according to 15% of the mass ratio of DPTS / TEOS, and place the resulting mixture in a reaction kettle , stirred at 40° C. for about 1 h, then heated to 80° C. for microwave hydrothermal treatment for 6 h, magnetically separated to obtain a solid product, and then fully washed. The washed product was redispersed in 100 mL of acidic ethanol solution, and refluxed at 60° C. for 12 h to remove the templating agent (P123). The obtained product is magnetically separated, fully washed with d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com