Alkali residue waste water treating method

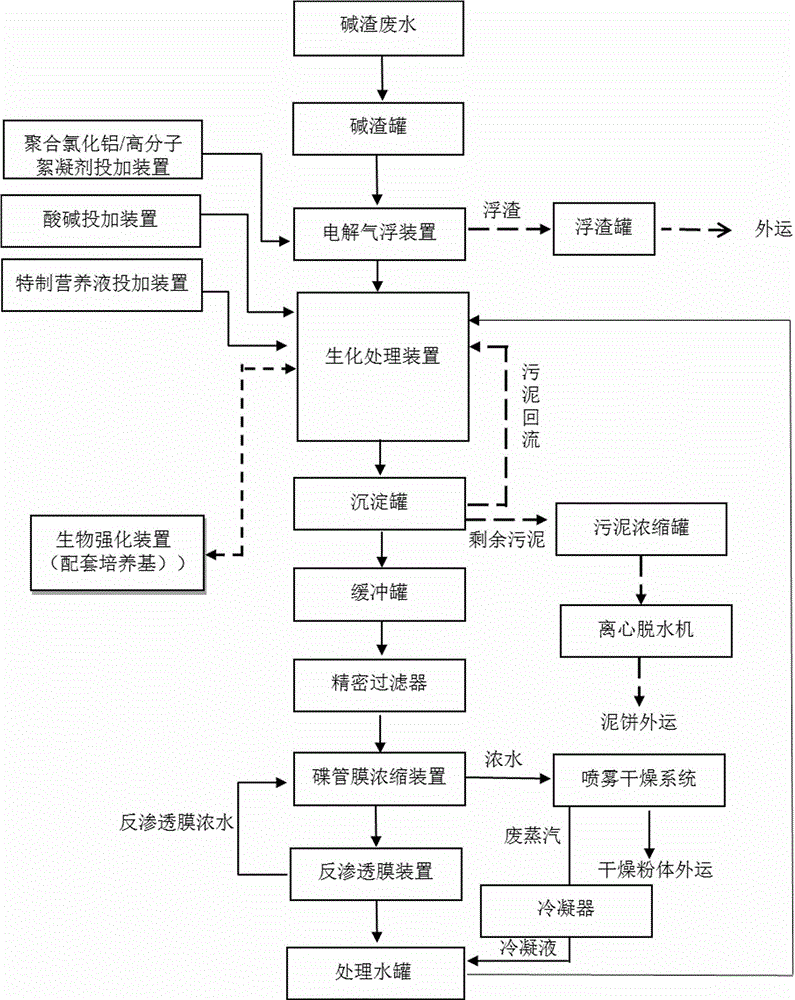

A technology for alkali slag wastewater and treatment methods, which is applied in water/sewage treatment, biological water/sewage treatment, multi-stage water/sewage treatment, etc., and can solve problems such as the influence of water production rate in the reuse system and the impact on stable and up-to-standard operation. To achieve the effect of convenient operation, strong practicability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A treatment method for alkali slag wastewater, comprising the steps of:

[0027] 1. Collect the alkali slag water into the alkali slag tank for storage, and send it to the electrolytic air flotation device through the lifting pump, add 200 mg / L polyaluminum chloride and 3 mg / L polymer coagulant polyacrylamide.

[0028] The electrolytic air flotation device uses insoluble electrodes, the anode is titanium plate coated iridium dioxide, and the cathode is stainless steel 316L. Under the action of a direct current electric field, the water molecules and sodium chloride are electrolyzed, and O is precipitated at the anode. 2 and Cl 2 , H is precipitated at the cathode 2 . The particle size of the bubbles produced by electrolysis is very small, with a particle size of 10-20 microns. Therefore, the bubbles produced by electrolysis have a higher ability to intercept impurity particles than dissolved air flotation and mechanical impeller air flotation, and the floating capaci...

Embodiment 2

[0042]Refinery alkali residue wastewater, daily treatment capacity 10t, main pollutant indicators COD200000mg / l, sulfide 26000mg / l, volatile phenol 3850mg / l, oil 260mg / l, pH14, NaOH content 3%, total solids concentration TDS150g / l , adopt the method of the present invention to process.

[0043] The alkali slag wastewater is first stored in the alkali slag tank to adjust the water quality and quantity, and then enters the electrolytic air flotation device through the lift pump, and adds 200 mg / L polyaluminium chloride and 3 mg / L polymer coagulant polyacrylamide, After electrolytic air flotation treatment, the oily substance is reduced to below 25mg / l.

[0044] The wastewater after electrolytic air flotation treatment enters the biochemical treatment device, and the total volume of the biochemical treatment device is 400m 3 According to the concentration of 1200mg / l, add 480kg of high-efficiency complex flora after screening and cultivation. The water ratio of alkali residue w...

Embodiment 3

[0048] Refinery alkali residue wastewater, daily treatment capacity 12t, main pollutant indicators COD350000mg / l, sulfide 32000mg / l, volatile phenol 1850mg / l, oil 390mg / l, pH14, NaOH content 3.5%, total solids concentration TDS180g / l , adopt the method of the present invention to process.

[0049] The alkali slag wastewater is first stored in the alkali slag tank to adjust the water quality and quantity, and then enters the electrolytic air flotation device through the lift pump, and adds 350 mg / L polyaluminium chloride and 6 mg / L polymer coagulant polyacrylamide, After electrolytic air flotation treatment, the oily substances are reduced to below 30mg / l.

[0050] The wastewater after electrolytic air flotation treatment enters the biochemical treatment device, and the total volume of the biochemical treatment device is 800m 3 According to the concentration of 1500mg / l, the high-efficiency complex flora after screening and cultivation is added for 1200kg. The water volume of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com