Method for preparing high-calorific-value fuel by utilizing fermentation residue of lignocellulosic material

A technology for lignocellulosic raw material and fermentation residue, which is applied in the field of preparing high-calorific value fuel by using lignocellulosic raw material fermentation residue, and achieves the effects of low nitrogen oxide and sulfide content, good mechanical performance and saving boiler energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

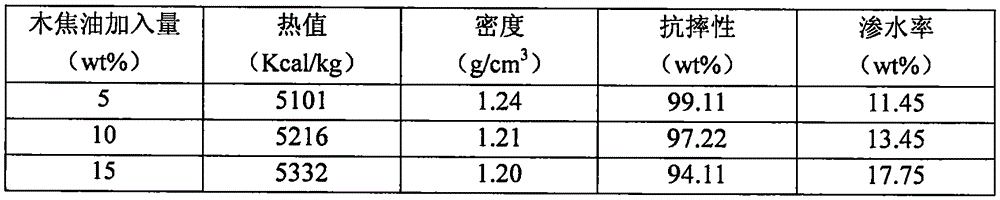

[0022] Take a certain quality of bagasse fermentation residue, wash it with water, and centrifuge it at a speed of 4,000 rpm for 10 minutes. Pour out the centrifuged liquid. The solid part has a light-colored protein layer and a dark-colored lignin layer. Use a medicine spoon The protein layer was separated, and the lignin layer was dried in an oven at 50° C. and crushed. The pulverized solid and wood tar are mixed at a mass ratio of 95 / 5, 90 / 10 and 85 / 15 respectively, and after stirring evenly, put into a briquetting machine to press into small pieces at a pressure of 10Mpa, and test its combustion performance and mechanical properties .

[0023] The specific test method is as follows: the calorific value is measured by the ZDHW-5000 calorimeter produced by Henan Hengke Instrument Factory; Put the fuel into the water for 5 seconds, absorb the water on the surface after taking it out, and weigh the mass change. The specific experimental data are shown in Table 1.

[0024] T...

Embodiment 2

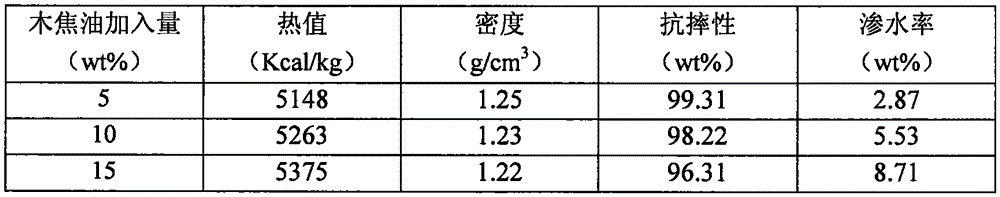

[0028] Take a certain quality of straw fermentation residue, and prepare fermentation residue powder according to the method in Example 1. The pulverized solid and wood tar are mixed at a mass ratio of 95 / 5, 90 / 10 and 85 / 15 respectively, and after stirring evenly, put into a briquetting machine to press into small pieces at a pressure of 10Mpa, and test its combustion performance and mechanical properties .

[0029] The specific test method is as described in Example 1, and the specific experimental data are shown in Table 2.

[0030] Table 2:

[0031]

[0032] It can be seen from Table 2 that the combustion performance and mechanical properties of straw fermentation residues are similar to those of bagasse fermentation residues. With the addition of wood tar, the fuel calorific value also gradually increases, but at the same time the fuel density gradually decreases, and the water permeability becomes larger, but its calorific value and density are slightly higher than t...

Embodiment 3

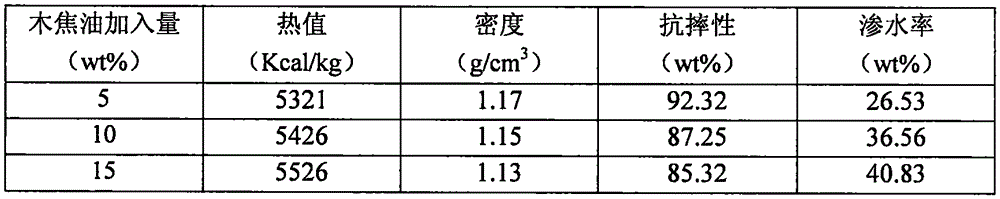

[0034] Take a certain quality of furfural slag fermentation residue, and prepare the fermentation residue powder according to the method in Example 1. The pulverized solid and wood tar are mixed at a mass ratio of 95 / 5, 90 / 10 and 85 / 15 respectively, and after stirring evenly, put into a briquetting machine to press into small pieces at a pressure of 10Mpa, and test its combustion performance and mechanical properties .

[0035] The specific test method is as described in Example 1, and the specific experimental data are shown in Table 3.

[0036] table 3:

[0037]

[0038] It can be seen from the table that the combustion performance and mechanical properties of furfural residue fermentation residue are similar to those of bagasse fermentation residue, but the drop resistance and water permeability are poor. This is because the lignin structure of furfural residue lignin is different from that of other fiber raw materials , It has undergone severe condensation itself, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com