Liquid crystal sealant and liquid crystal display unit using same

A technology of liquid crystal display unit and liquid crystal sealant, which is applied in the direction of instruments, optics, nonlinear optics, etc. It can solve the problems of unrecorded moisture permeability, low Tg, and slow response speed, etc., and achieve low liquid crystal pollution and excellent low water absorption , good penetration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0181] Hereinafter, the present invention will be described in more detail through synthesis examples and examples, but the present invention is not limited by the examples. In addition, unless otherwise stated, "part" and "%" are based on mass here.

Synthetic example 1

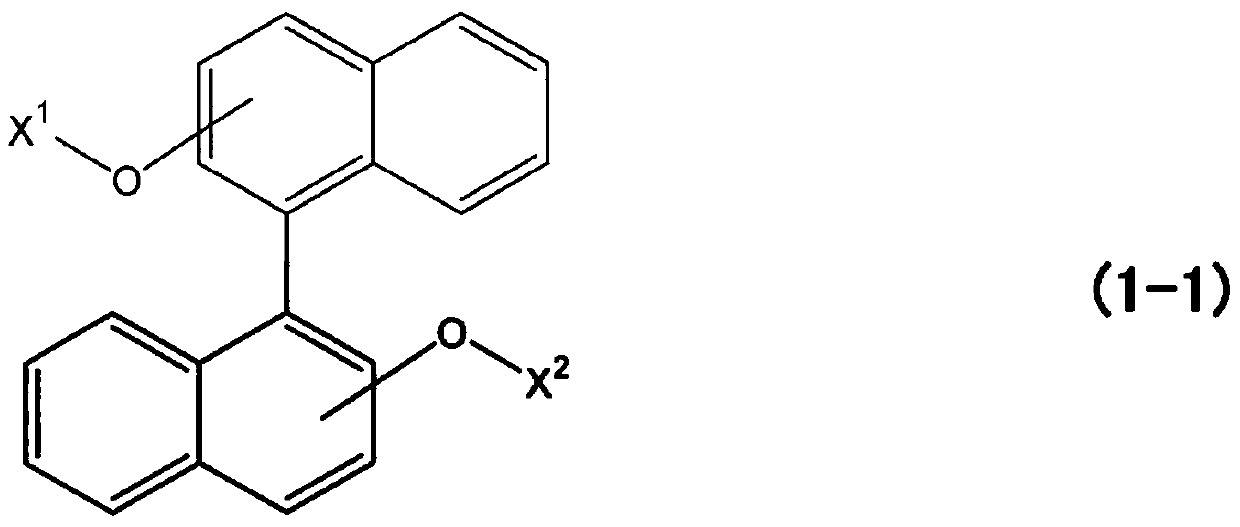

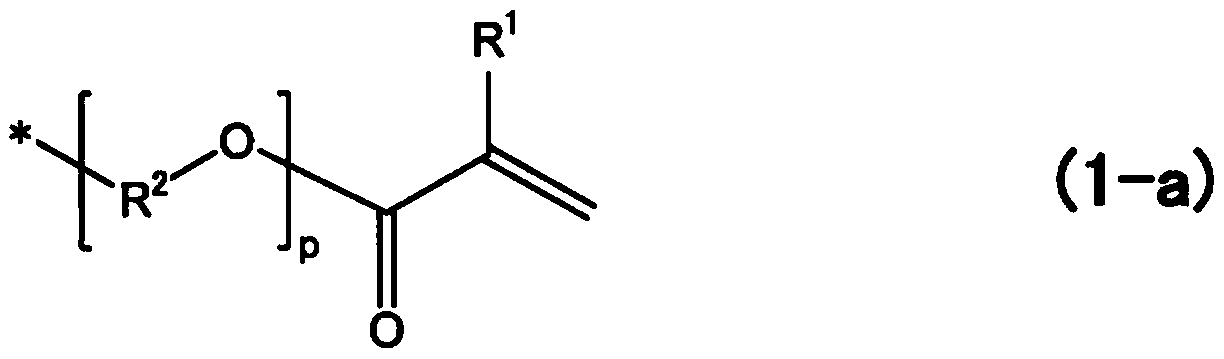

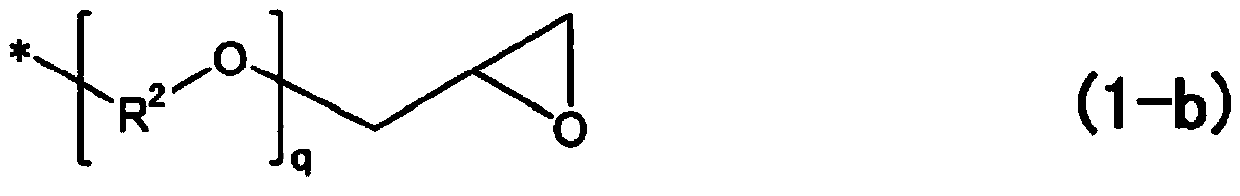

[0182] [Synthesis Example 1: Synthesis of 1,1-bi-2-binaphthol polyethoxy acrylate]

[0183] In a flask equipped with a stirring device, a reflux tube, and a thermometer, 286.3 g (1.0 mol) of 1,1'-bi-2-naphthol, 264.2 g (3.0 mol) of ethylene carbonate, and 41.5 g of lithium carbonate ( 0.3mol), toluene 2000mL, and reacted at 110° C. for 12 hours.

[0184] After the reaction, the obtained reaction liquid was washed with water, washed with a 1% NaOH aqueous solution, and then washed with water until the washing water became neutral. Using a rotary evaporator, the solvent was distilled off from the solution washed with water under reduced pressure to obtain 300.0 g of a reaction product of 1,1'-bi-2-naphthol with 2 mol of ethylene oxide.

[0185] Then, in a flask equipped with a stirring device, a reflux tube, a thermometer and a water separator, 187.2 g (0.5 mol) of ethylene oxide 2 mol reactant of 1,1'-bi-2-naphthol, 86.5 mol of acrylic acid g (2.4mol), 0.95g of p-toluenesulfo...

Synthetic example 2

[0186] [Synthesis Example 2: Synthesis of 1,2-bis(trimethylsilyloxy)-1,1,2,2-tetraphenylethane]

[0187] In a flask equipped with a stirring device, a reflux tube, and a thermometer, 100 parts (0.28 mol) of commercially available benzopinacol (manufactured by Tokyo Chemical Industry Co., Ltd.) were dissolved in 350 parts of dimethylformaldehyde. 32 parts (0.4 mol) of pyridine as a base catalyst and 150 parts (0.58 mol) of BSTFA (manufactured by Shin-Etsu Chemical Co., Ltd.) as a silylating agent were added thereto, and after heating up to 70 degreeC, it stirred for 2 hours. The obtained reaction liquid was cooled, and 200 parts of water were added, stirring, and the product was precipitated, and the unreacted silylating agent was deactivated. After the precipitated product was separated by filtration, it was sufficiently washed with water. Then, the obtained product was dissolved in acetone, and water was added to recrystallize it for purification. 105.6 parts of target 1,2-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com