Calcium alginate composite microspheres for stabilizing water-in-oil type Pickering emulsion and preparation method thereof

A technology of Pickering emulsion and calcium alginate, which is applied in the field of calcium alginate composite microspheres and its preparation, can solve the problems of limited application, reduction of hydrophilicity, inability to stabilize water-in-oil Pickering emulsion, etc., and achieve Broad application prospects, strong practicability, and the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

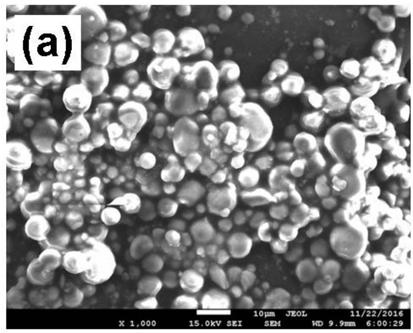

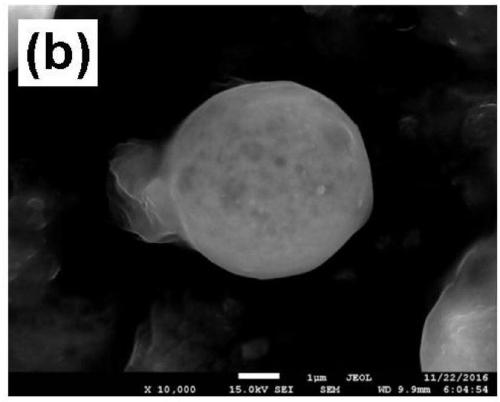

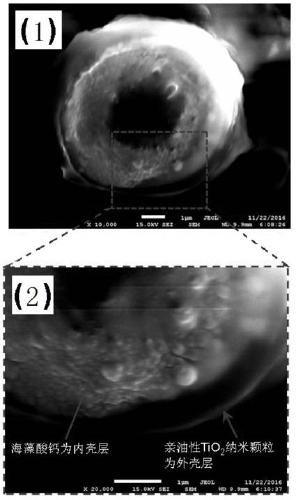

Image

Examples

Embodiment 1

[0047] (1) Alkylsilane-grafted TiO 2 Preparation of nanoparticles: (1) 1 g of commercially available TiO with a particle size of 25 nm 2 Nanoparticles were added to 15 mL of 30% by volume H 2 o 2 solution, ultrasonically dispersed for 5 min to obtain a dispersion; (2) sealed the dispersion and placed it in a dark place with magnetic stirring at 500 rpm for 2 h, unsealed and dried at 40 °C to obtain hydroxylated TiO 2 Nanoparticle powder; (3) The dried hydroxylated TiO 2 Nanoparticle powder was added to a mixture of 0.2 mL octaalkyltrichlorosilane and 19.8 mL n-hexane, ultrasonically dispersed for 5 min, and magnetically stirred at 500 rpm for 8 h, during which n-hexane was added to maintain the initial liquid level; (4) the previous The dispersion obtained in the step was centrifuged at 12000 rpm for 5 minutes at 4 °C, and the precipitate was dried at 40 °C to obtain the alkylsilane-grafted TiO 2 nanoparticles.

[0048] (2) Preparation of water-in-oil sodium alginate Pick...

Embodiment 2

[0053] (1) Alkylsilane-grafted SiO 2 Preparation of nanoparticles: (1) 1.8 g of commercially available SiO with a particle size of 25 nm 2 Nanoparticles were added to 15 mL of 30% by volume H 2 o 2 In the solution, ultrasonically disperse for 10 min to obtain a dispersion; (2) Seal the dispersion and place it in a dark place with magnetic stirring at 800 rpm for 6 h, unseal and dry at 60 °C to obtain hydroxylated SiO 2 nanoparticle powder; (3) the dried hydroxylated SiO 2 Nanoparticle powder was added to a mixture of 1 mL octaalkyltrichlorosilane and 19 mL n-hexane, ultrasonically dispersed for 10 min, and magnetically stirred at 800 rpm for 12 h, during which n-hexane was added to maintain the initial liquid level; (4) the previous The dispersion obtained in the step was centrifuged at 15000 rpm for 15 minutes at 4 °C, and the precipitate was dried at 60 °C to obtain the SiO grafted with alkylsilane. 2 nanoparticles.

[0054] (2) Preparation of water-in-oil sodium algina...

Embodiment 3

[0059] (1) Alkylsilane-grafted Fe 3 o 4 Preparation of nanoparticles: (1) 1.5 g of commercially available Fe with a particle size of 25 nm 3 o 4 Nanoparticles were added to 15 mL of 30% by volume H 2 o 2 solution, ultrasonically disperse for 8 min to obtain a dispersion; (2) seal the dispersion and place it in a dark place with magnetic stirring at 700 rpm for 4 h, unseal and dry at 50 °C to obtain hydroxylated Fe 3 o 4 Nanoparticle powder; (3) the hydroxylated modified Fe after drying 3 o 4Nanoparticle powder was added to a mixture of 0.5 mL octaalkyltrichlorosilane and 19.5 mL n-hexane, ultrasonically dispersed for 8 min, and magnetically stirred at 700 rpm for 10 h, during which n-hexane was added to maintain the initial liquid level; (4) the previous The dispersion obtained in the step is centrifuged at 13000 rpm for 10 min at 4 °C, and the precipitate is dried at 50 °C to obtain the alkylsilane-grafted Fe 3 o 4 nanoparticles.

[0060] (2) Preparation of water-in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com