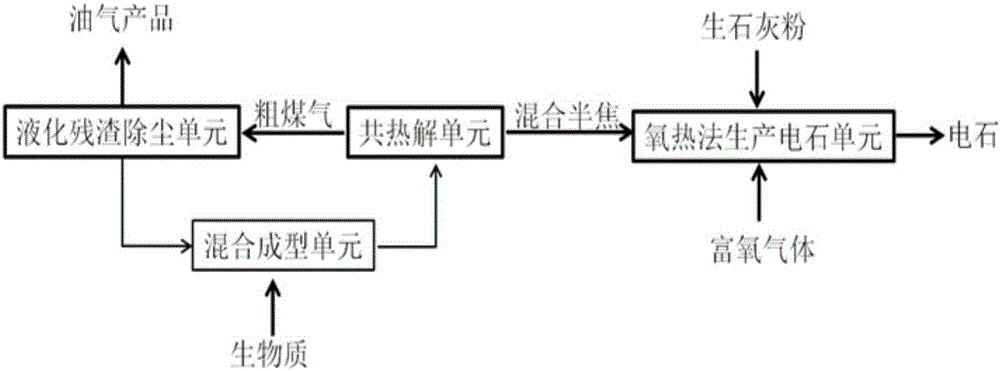

System and method for pyrolyzing biomass and liquefied residue

A technology for liquefying residues and biomass, applied in the chemical industry, can solve the problems of easy generation of dust, low specific gravity of biomass, high dust content of pyrolysis oil and gas, and achieve the effect of reducing raw material costs and production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

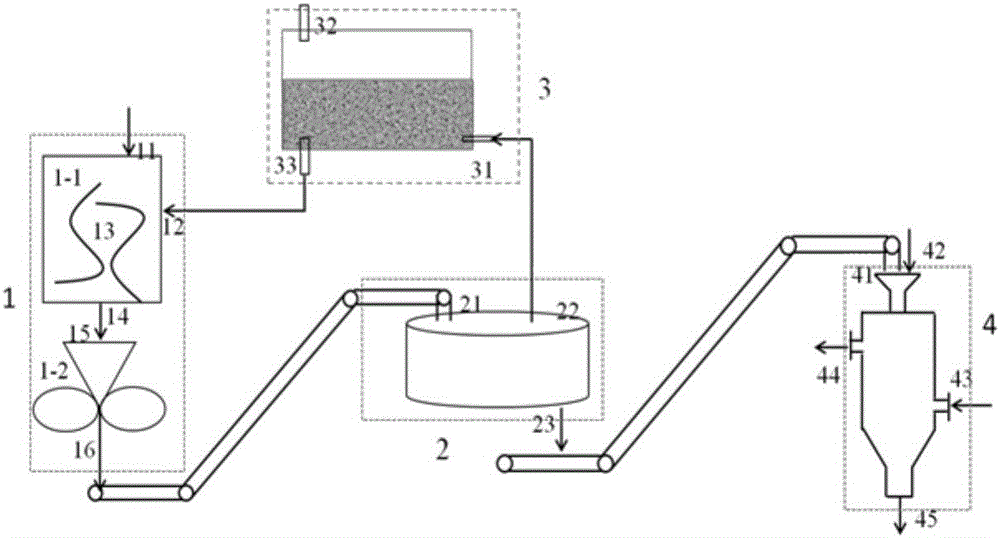

Embodiment 1

[0064] Using the system of the present invention, the agricultural waste with a particle size of less than 5mm and the liquefied residue at 290°C sent from the liquefied residue dedusting unit are mixed and stirred in a kneader, and the mass ratio of the biomass to the liquefied residue is 1 :0.5, and then pressed into shape by a briquetting machine, and sent into the non-heat-carrier regenerative rotary bed through a screw conveyor, evenly distributed on the material plate of the preheating furnace and rotated from the inlet to the outlet in turn, and in the process of rotation Heating in the radiant tube, pyrolysis occurs, and pyrolysis oil gas and mixed semi-coke are produced; among them, the temperature of the feed inlet is relatively low, which is 400-450°C, and the pyrolysis temperature of the uniform temperature field is 550-600°C; the pyrolysis The generated pyrolysis oil and gas are collected from each pyrolysis gas outlet and then merged, and directly transported to t...

Embodiment 2

[0066] This embodiment is the same as the system used in the above-mentioned embodiment 1, but the process conditions are different, as described below. The agricultural waste with a particle size of less than 5mm and the liquefied residue at 260°C sent by the liquefied residue dedusting unit are mixed and stirred in a kneader. The mass ratio of the biomass to the liquefied residue is 1:0.2, and then pressed The ball machine is pressed and formed, and sent into the non-heat carrier regenerative rotary bed through the screw conveyor, evenly distributed on the material plate of the preheating furnace, rotated from the entrance to the exit, and heated by the radiant tube during the rotation process, Pyrolysis occurs to produce pyrolysis oil gas and mixed semi-coke; among them, the temperature of the feed inlet is relatively low, which is 400-450°C, and the pyrolysis temperature of the uniform temperature field is 500-550°C; the pyrolysis oil gas produced by pyrolysis is from All ...

Embodiment 3

[0068] This embodiment is the same as the system used in the above-mentioned embodiment 1, but the process conditions are different, as described below. The agricultural waste with a particle size of less than 5mm and the liquefied residue at 360°C sent by the liquefied residue dedusting unit are mixed and stirred in a kneader. The mass ratio of the biomass to the liquefied residue is 1:0.6, and then pressed The ball machine is pressed and formed, and sent into the non-heat carrier regenerative rotary bed through the screw conveyor, evenly distributed on the material plate of the preheating furnace, rotated from the entrance to the exit, and heated by the radiant tube during the rotation process, Pyrolysis occurs, producing pyrolysis oil gas and mixed semi-coke; among them, the temperature of the feed inlet is relatively low, which is 450-480°C, and the pyrolysis temperature of the uniform temperature field is 600-650°C; the pyrolysis oil gas produced by pyrolysis is from The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com