Preparation method and application for bismuth sulfide-bismuth ferrate composite visible-light photocatalyst

A bismuth ferrite and catalyst technology, which is applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of unsatisfactory photocatalytic activity and high recombination rate of photogenerated carriers, and achieve convenient industrialization Promotion, high catalytic activity, abundant and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

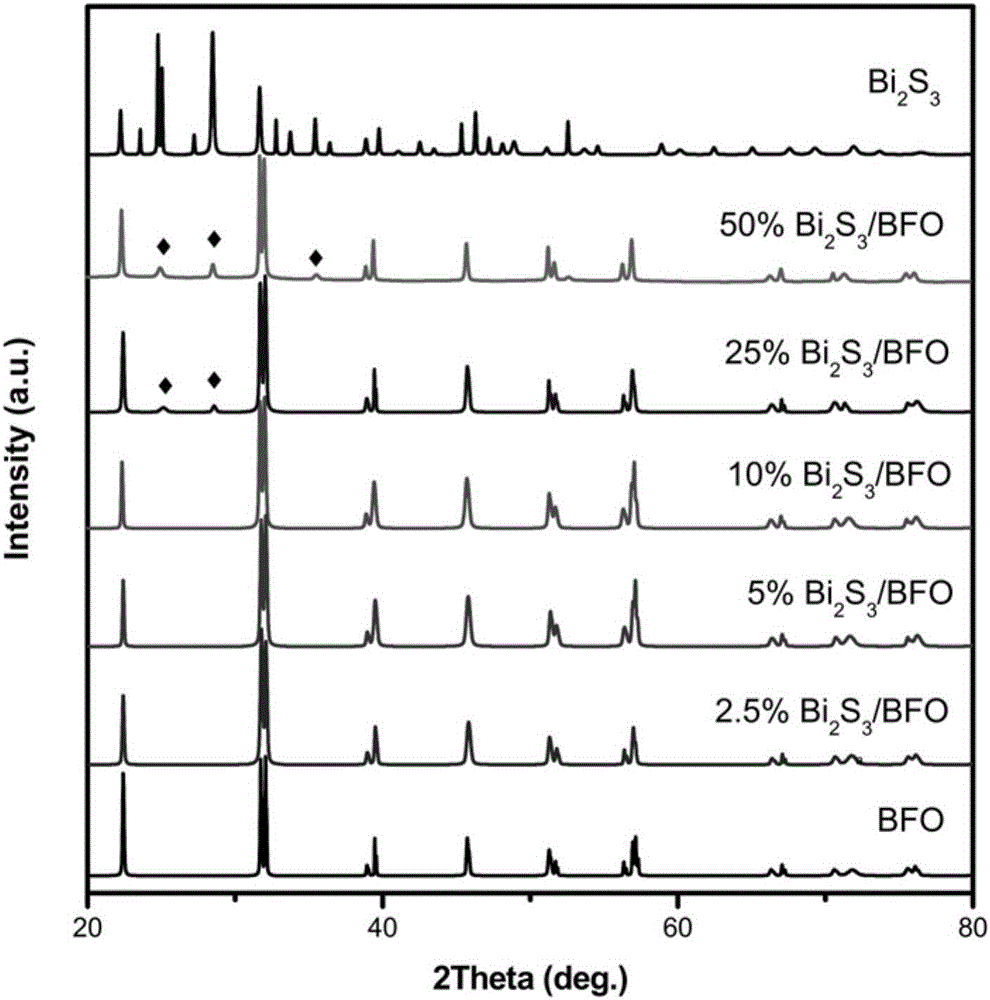

[0034] A kind of bismuth sulfide-bismuth ferrite composite visible light catalyst, the steps of its preparation method are as follows:

[0035] 1) Using bismuth source and iron source as raw materials, mix and dissolve them in the organic solvent ethylene glycol according to the molar ratio of bismuth and iron elements at a ratio of 1:1 to prepare a precursor liquid, and ultrasonically disperse at 60°C for 0.5 h, obtaining a sol, the molar ratio of the bismuth element in the bismuth source and the iron element in the iron source is 1:1; the bismuth source is bismuth nitrate and hydrate thereof, and the iron source is iron nitrate and hydrate thereof;

[0036]2) drying the prepared sol at 120° C. for 4-5 days to obtain xerogel powder;

[0037] 3) After grinding the obtained xerogel powder evenly, put it into a muffle furnace for pretreatment; the treatment temperature is 300°C, and the time is 2h;

[0038] 4) Calcining the pretreated xerogel powder in a muffle furnace at a tem...

Embodiment 2

[0042] A kind of bismuth sulfide-bismuth ferrite composite visible light catalyst, the steps of its preparation method are as follows:

[0043] 1) Using bismuth source and iron source as raw materials, mix and dissolve the two in proportion to the organic solvent ethylene glycol to prepare a precursor solution, and ultrasonically disperse at a temperature of 75°C for 1 hour to obtain a sol. The bismuth in the bismuth source The molar ratio of the iron element in the element and the iron source is 1:1; the bismuth source is bismuth nitrate and hydrate thereof, and the iron source is iron nitrate and hydrate thereof;

[0044] 2) drying the prepared sol at 125° C. for 4 days to obtain xerogel powder;

[0045] 3) After grinding the obtained xerogel powder evenly, put it into a muffle furnace for pretreatment; the treatment temperature is 350°C, and the time is 2h;

[0046] 4) The pretreated xerogel powder was calcined in a muffle furnace at a temperature of 550° C. for 3 hours, t...

Embodiment 3

[0050] A kind of bismuth sulfide-bismuth ferrite composite visible light catalyst, the steps of its preparation method are as follows:

[0051] 1) Using bismuth source and iron source as raw materials, mix and dissolve the two in proportion to the organic solvent ethylene glycol to prepare a precursor solution, and ultrasonically disperse at 80°C for 1 hour to obtain a sol. The bismuth in the bismuth source The molar ratio of the iron element in the element and the iron source is 1:1; the bismuth source is bismuth nitrate and hydrate thereof, and the iron source is iron nitrate and hydrate thereof;

[0052] 2) drying the prepared sol at 120° C. for 5 days to obtain xerogel powder;

[0053] 3) After grinding the obtained xerogel powder evenly, put it into a muffle furnace for pretreatment; the treatment temperature is 350°C, and the time is 3h;

[0054] 4) The pretreated xerogel powder was calcined in a muffle furnace at a temperature of 600° C. for 2 hours, then cooled to roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com