Petroleum hydrocarbon contaminated remediation fertilizer

A technology of petroleum hydrocarbons and fertilizers, which is applied in the field of repairing fertilizers polluted by petroleum hydrocarbons. It can solve the problems of impact, long temporary storage time, and high pretreatment requirements, and achieve the effect of rich nutrition, rich nutrition, and high removal rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

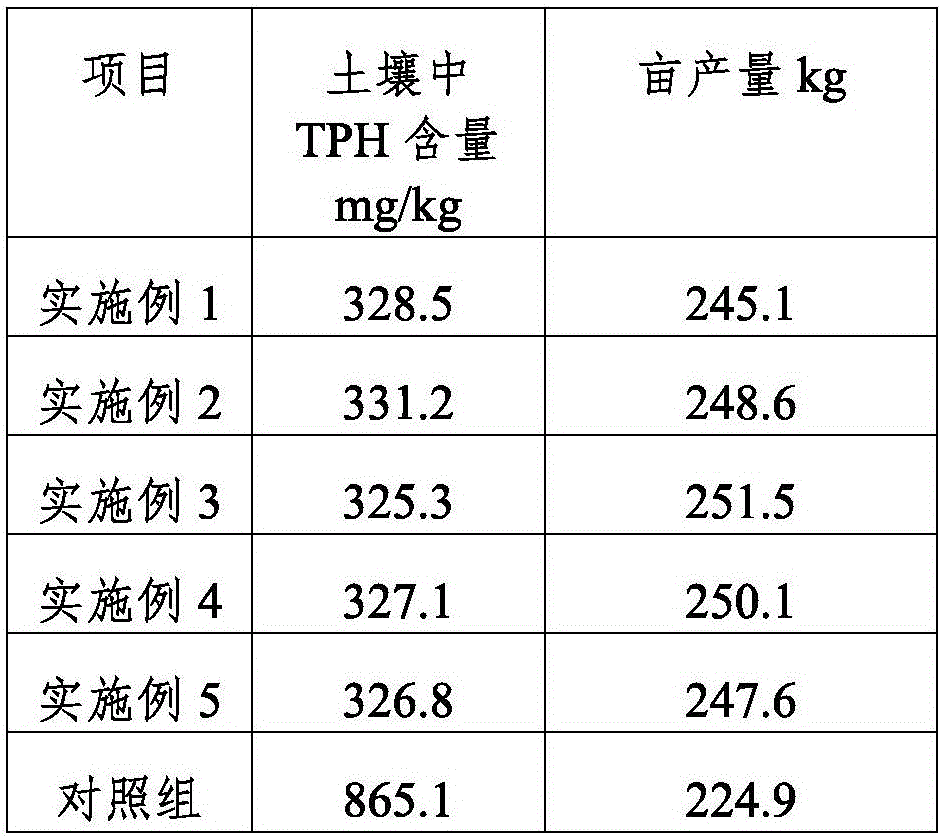

Examples

Embodiment 1

[0021] A repairing fertilizer for petroleum hydrocarbon pollution, characterized in that it consists of the following raw materials in parts by weight: 20kg of urea, 10kg of sodium nitrate, 15kg of urea phosphate, 10kg of superphosphate, 10kg of potassium sulfate, 12kg of potassium carbonate, and 15kg of potassium tartrate , 8kg of sodium carbonate, 10kg of peanut dregs, 8kg of bagasse, 18kg of modified biochar, 10kg of modified silica gel, and 15kg of modified distiller's grains.

[0022] The preparation method of the modified biochar is to soak the biochar with oxalic acid, stir with a magnetic stirrer for 35 minutes under a constant temperature water bath at 75°C, adjust the pH value to 7 with 0.4mol / L sodium hydroxide, and stir for 10 minutes , take it out, soak it in hydrogen peroxide, stir it with a magnetic stirrer for 65 minutes under a constant temperature water bath at 60°C, add hexadecyltrimethylammonium bromide 0.3 times the mass of the biomass charcoal, let it stan...

Embodiment 2

[0031] A repairing fertilizer for petroleum hydrocarbon pollution, characterized in that it consists of the following raw materials in parts by weight: 30kg of urea, 15kg of sodium nitrate, 20kg of urea phosphate, 15kg of superphosphate, 30kg of potassium sulfate, 18kg of potassium carbonate, and 20kg of potassium tartrate , 12kg of sodium carbonate, 15kg of peanut dregs, 14kg of bagasse, 22kg of modified biochar, 14kg of modified silica gel, and 20 kg of modified distiller's grains.

[0032] The modified biochar is prepared by soaking the biochar with oxalic acid, stirring with a magnetic stirrer for 40 minutes under a constant temperature water bath at 80°C, adjusting the pH value to 7 with 0.45mol / L sodium hydroxide, and stirring for 10 minutes , take it out, soak it in hydrogen peroxide, stir it with a magnetic stirrer for 70 minutes in a constant temperature water bath at 65°C, add cetyltrimethylammonium bromide 0.35 times the mass of the biochar, let it stand at 6°C for 1...

Embodiment 3

[0041] A repairing fertilizer for petroleum hydrocarbon pollution, characterized in that it consists of the following raw materials in parts by weight: urea 25 kg, sodium nitrate 13 kg, urea phosphate 18 kg, superphosphate 13 kg, potassium sulfate 20 kg, potassium carbonate 15 kg, potassium tartrate 18 kg , 10kg of sodium carbonate, 13kg of peanut dregs, 12kg of bagasse, 20kg of modified biochar, 12kg of modified silica gel, and 18kg of modified distiller's grains.

[0042] The modified biochar is prepared by soaking the biochar with oxalic acid, stirring with a magnetic stirrer for 38 minutes under a constant temperature water bath at 78°C, adjusting the pH value to 7 with 0.43mol / L sodium hydroxide, and stirring for 10 minutes , take it out, soak it in hydrogen peroxide, stir it with a magnetic stirrer for 68 minutes in a constant temperature water bath at 63°C, add cetyltrimethylammonium bromide 0.33 times the mass of the biochar, let it stand at 5°C for 1.3h, and filter , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com