Water-based pollution-resistant reflective thermal insulation coating and preparation method thereof

A reflective heat-insulating coating and anti-fouling technology, which is applied in the direction of reflective/signal coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problem of difficulty in meeting energy saving and environmental protection durability, difficult control of the production process, and poor reflective heat insulation effect and other problems, to achieve the effect of low construction cost and maintenance cost, good decorative effect, and not easy to scar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

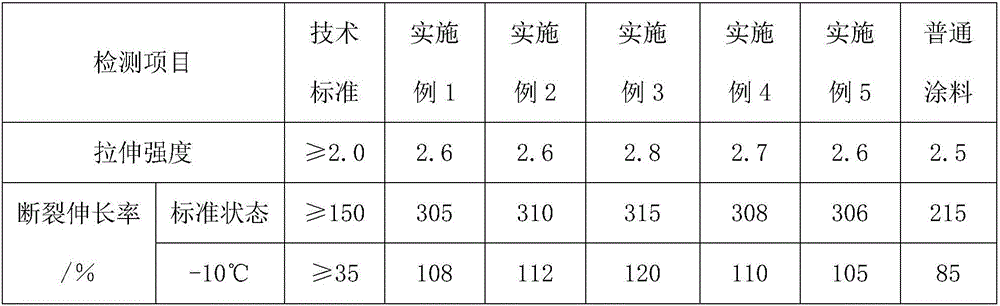

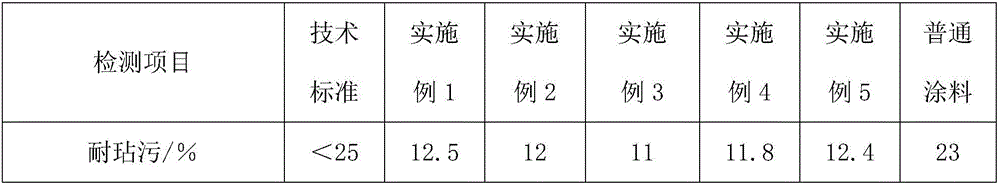

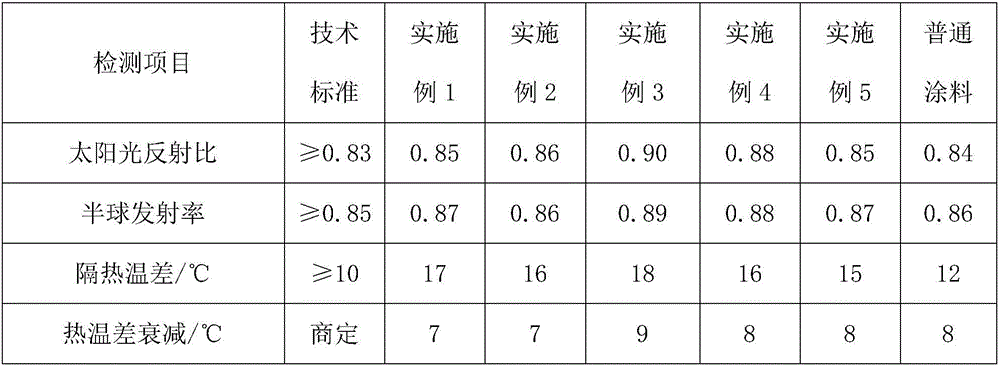

Examples

Embodiment 1

[0024] The water-based stain-resistant reflective heat-insulating coating is prepared from the following raw materials in parts by weight: 40 parts of pure acrylic emulsion, 3 parts of nano-titanium dioxide, 2 parts of polybenzimidazole, 2 parts of sodium tetraborate, 6 parts of hydroxyethyl cellulose, 5 parts of boron carbide, 4 parts of antimony-doped tin oxide, 12 parts of hollow ceramic microspheres, 8 parts of hydrophobic modified sodium carboxylate, 6 parts of zirconia fiber, 6 parts of water glass, 16 parts of ethylene glycol, deionized 30 parts of water.

[0025] The preparation steps of the above-mentioned water-based stain-resistant reflective heat-insulating coating are as follows:

[0026] (1) Add deionized water and dispersant into the container, and disperse at 600r / min for 10min;

[0027] (2) Increase the rotational speed to 800r / min, and heat it in a constant temperature water bath to 40°C, add nanoparticles, inorganic non-metallic compounds, and reflective pi...

Embodiment 2

[0032] The water-based stain-resistant reflective heat-insulating coating is prepared from the following raw materials in parts by weight: 42 parts of acrylic emulsion, 3.5 parts of nano-titanium dioxide, 2.5 parts of polybenzimidazole, 2.5 parts of sodium tetraborate, 6.5 parts of hydroxyethyl cellulose, carbonized 5.5 parts of silicon, 4.5 parts of indium-doped tin oxide, 13 parts of mica micropowder, 8.5 parts of hydrophobic modified sodium carboxylic acid salt, 6.5 parts of alumina fiber, 6.5 parts of aluminum dihydrogen phosphate, 17 parts of ethylene glycol, deionized water 33 servings.

[0033] The preparation steps of the above-mentioned water-based stain-resistant reflective heat-insulating coating are as follows:

[0034] (1) Add deionized water and dispersant to the container, and disperse at 650r / min for 8min;

[0035] (2) Increase the rotation speed to 850r / min, and heat it in a constant temperature water bath to 42°C, add nanoparticles, inorganic non-metallic co...

Embodiment 3

[0040] Water-based stain-resistant reflective heat-insulating coating, prepared from the following raw materials in parts by weight: 45 parts of vinegar acrylic emulsion, 4 parts of nano-silica, 3 parts of polybenzimidazole, 3 parts of sodium tetraborate, 7 parts of hydroxyethyl cellulose 6 parts of boron nitride, 5 parts of aluminum-doped zinc oxide, 14 parts of zeolite powder, 9 parts of polyacrylic acid sodium salt, 7 parts of carbon fiber, 7 parts of silica sol, 18 parts of ethylene glycol, and 35 parts of deionized water.

[0041] The preparation steps of the above-mentioned water-based stain-resistant reflective heat-insulating coating are as follows:

[0042] (1) Add deionized water and dispersant to the container, and disperse at 700r / min for 8min;

[0043] (2) Increase the rotation speed to 800r / min, and heat it in a constant temperature water bath to 45°C, add nanoparticles, inorganic non-metallic compounds, and reflective pigments in sequence, and stir and disperse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com