Ultraviolet-cured acrylate adhesive preparation method and product

A technology of acrylate and adhesive, which is applied in the field of preparation of UV-cured acrylate adhesive, can solve the problem of affecting the modification efficiency of liquid nitrile rubber to acrylate adhesive, the unsaturated double bond activity of nitrile rubber is not very high, and the nitrile Low light transmittance of rubber and other problems, to achieve the effect of low cost, improved comprehensive performance, and improved transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

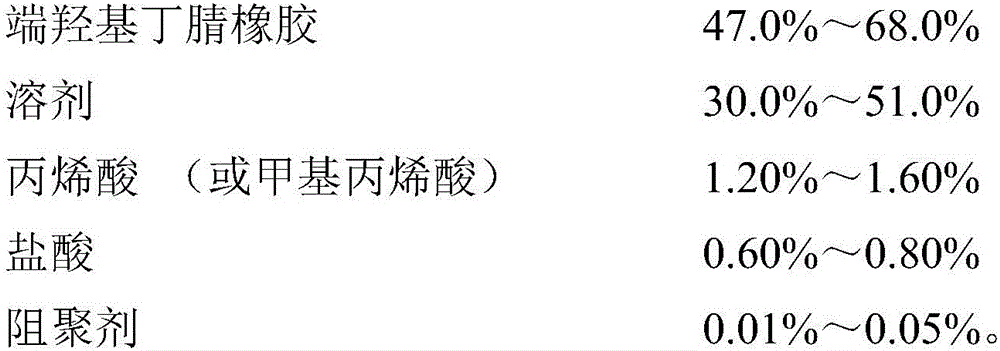

Embodiment 1

[0032] First, add 300.00kg of hydroxyl-terminated nitrile rubber (molecular weight 2000-3000, hydroxyl value 0.4-0.5mmol / g), 315.00kg of toluene, 9.73kg of acrylic acid, p- Hydroquinone 158.00g, 37% hydrochloric acid 4.80kg, start the agitator, heat to the reaction system reflux phenomenon, and maintain the reaction at this temperature; React, lower the temperature to 55.0°C, vacuum out and recover the solvent toluene, and then discharge when the temperature is lowered to below 40°C, and the obtained acrylic-terminated nitrile rubber is ready for use.

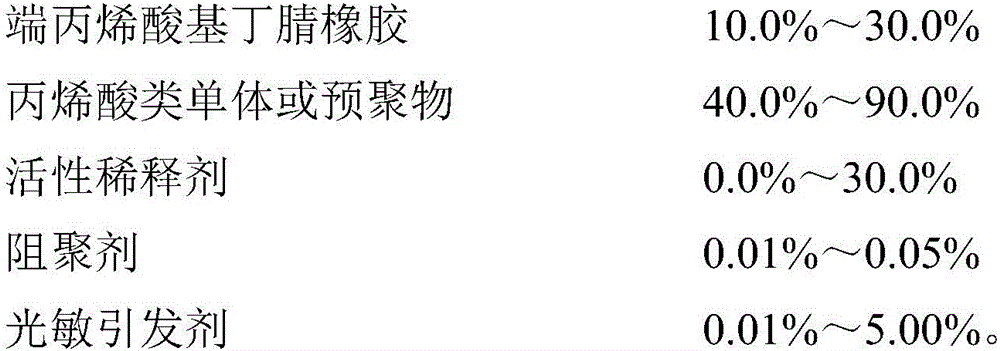

[0033] Then, 110.00kg of acrylate-terminated nitrile rubber prepared above, 390.00kg of E51 epoxy acrylate, 8.00kg of trimethylolpropane triacrylate, 50.00kg of acrylic acid, 300.00kg of methyl acrylate, and 100.00kg of tetrahydrofuryl methacrylate kg, 0.50kg of tert-butylcatechol, 40.00kg of benzoin butyl ether, and 10.00kg of benzophenone were added to the mixing kettle, the temperature was raised to 30.0°C, stirred for 30.0m...

Embodiment 2

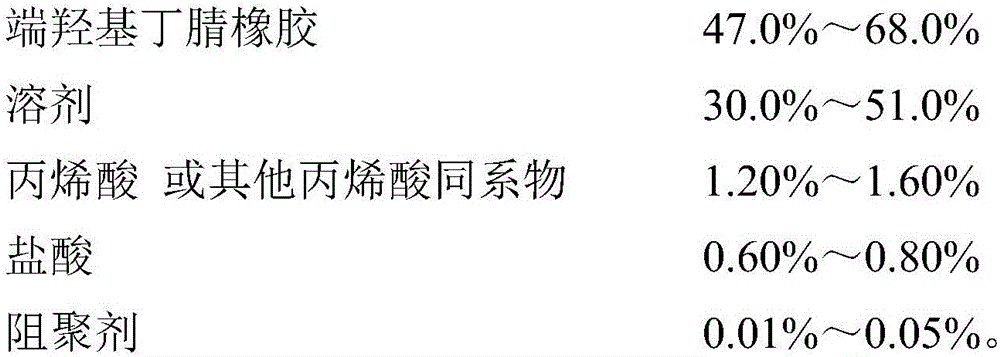

[0036]First, add 448.00kg of hydroxy-terminated nitrile rubber, 200.00kg of benzene, 8.06kg of acrylic acid, 66.00g of p-benzoquinone, and 4.03kg of 37% hydrochloric acid into a reaction kettle with a condenser and a water separator, start the stirrer, and heat to The reaction system refluxed, and the reaction was maintained at this temperature; when most of the theoretical water output was evaporated, the heating was stopped, the reaction was terminated, the temperature was lowered to 50.0 °C, the solvent benzene was vacuumed and recovered, and then the temperature was lowered to When the temperature is below 40°C, the material can be discharged, and the obtained acrylic-terminated nitrile rubber is ready for use.

[0037] Then, 300.00kg of acrylic-terminated nitrile rubber prepared above, 150.00kg of polyethylene glycol (200) acrylate, 200.00kg of vinyl acetate, 100.00kg of vinyl diglycol ether, 60.00kg of methacrylic acid, methyl Add 200.00kg of methyl acrylate, 0.15kg of p...

Embodiment 3

[0040] First, in a reactor with a condenser and a water separator, add 390.00kg of hydroxy-terminated nitrile rubber, 265.00kg of xylene mixed solvent, 9.75kg of methacrylic acid, 190.00g of hydroquinone, 4.88kg of 37% hydrochloric acid, Start the agitator, heat until the reaction system refluxes, and maintain the reaction at this temperature; when the reaction reaches the point where most of the theoretical water output is evaporated, stop heating, end the reaction, lower the temperature to 50.0°C, vacuum out and recover The solvent is xylene, and then the material can be discharged when the temperature is lowered to below 40°C to obtain acrylic-terminated nitrile rubber for later use.

[0041] Then, 200.00kg of the above-mentioned prepared acrylate-terminated nitrile rubber, 200.00kg of polyurethane acrylate, 100.00kg of E44 epoxy methacrylate, 20.00kg of diallyl phthalate, diethylene glycol divinyl ether 80.00kg, methacrylic acid 30.00kg, isooctyl methacrylate 150.00kg, met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com