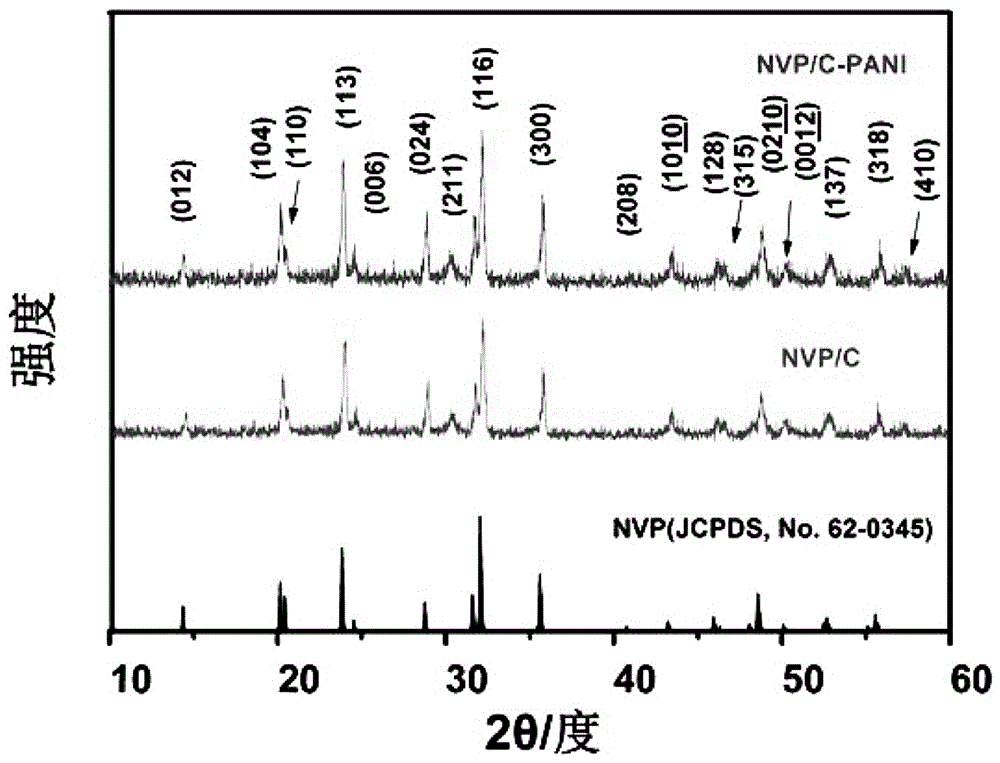

Conductive high molecular polyaniline modified sodium vanadium phosphate anode material and preparation method thereof

A technology of conducting polymer and sodium vanadium phosphate, which is applied in the field of electrochemical power supply, can solve the problems of low electronic conductivity and poor high-rate performance, and achieve the effects of simple synthesis process, low cost, and reduced charge transfer resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

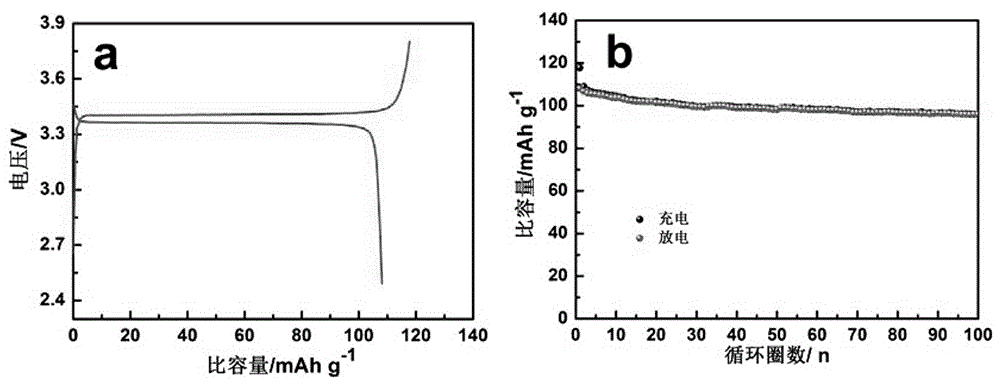

Embodiment 1

[0020] Sodium source Na 2 CO 3 , vanadium source NH 4 VO 3 and phosphorus source NH 4 h 2 PO 4 After ball milling in absolute ethanol medium with a molar ratio of 1.5:2:3, dry it, and pre-calcine it at 350°C for 6 hours under a nitrogen atmosphere to obtain a precursor; add 5 wt.% glucose to the precursor, ball mill After 2 hours, it was dried in an oven at 50°C; the obtained powder was sintered in a tube furnace at 700°C for 10 hours under a nitrogen atmosphere; after cooling, it was ground and sieved to obtain NVP / C. The resulting NVP / C was added to 200 mL of 1M HCl ethanol / water solution (volume ratio 1:1) and sonicated for 30 minutes. Add 5 wt.% AN to the suspension (the amount of aniline monomer added is 5wt.% of the total mass of the carbon-coated lithium vanadium phosphate NVP / C raw material), and stir at room temperature for 30 minutes. Then add APS according to the molar ratio of AN and APS of 1: 1.5, stir magnetically at 0~5°C for 6 hours to obtain a black sub...

Embodiment 2

[0022] Sodium source Na 2 CO 3 , vanadium source NH 4 VO 3 and phosphorus source NH 4 h 2 PO 4 After ball milling in absolute ethanol medium with a molar ratio of 1.5 : 2 : 3, dry it, and pre-calcine it at 350°C for 6 hours under a nitrogen atmosphere to obtain a precursor; add 5wt.% glucose to the precursor, and ball mill it for 2 After 1 hour, it was dried in an oven at 50°C; the obtained powder was sintered in a tube furnace at 700°C for 10 hours under a nitrogen atmosphere; after cooling, it was ground and sieved to obtain NVP / C. The resulting NVP / C was added to 200 mL of 1M HCl ethanol / water solution (volume ratio 1:1) and sonicated for 30 minutes to obtain a suspension. 8wt.% AN was added to the suspension (the amount of aniline monomer added was 8wt.% of the total mass of the carbon-coated lithium vanadium phosphate NVP / C raw material), and stirred at room temperature for 30 minutes. Then add APS according to the molar ratio of AN and APS of 1: 1.5, stir magnetic...

Embodiment 3

[0024] Sodium source Na 2 CO 3 , vanadium source NH 4 VO 3 and phosphorus source NH 4 h 2 PO 4 After ball milling in absolute ethanol medium with a molar ratio of 1.5 : 2 : 3, dry and pre-calcine at 350°C for 6 hours under a nitrogen atmosphere to obtain a precursor; add 5wt.% glucose to the precursor, and ball mill for 2 After 1 hour, it was dried in an oven at 50°C; the obtained powder was sintered in a tube furnace at 700°C for 10 hours under a nitrogen atmosphere; after cooling, it was ground and sieved to obtain NVP / C. The resulting NVP / C was added to 200 mL of 1M HCl in ethanol / water solution (volume ratio 1:1) and sonicated for 30 minutes. 11wt.% AN was added to the suspension (the amount of aniline monomer added was 11wt.% of the total mass of the carbon-coated lithium vanadium phosphate NVP / C raw material), and stirred at room temperature for 30 minutes. Then add APS according to the molar ratio of AN and APS of 1: 1.5, stir magnetically at 0~5°C for 6 hours to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com