Preparation method and application of nanometer silicon array negative electrode material

A negative electrode material and nano-array technology, which is applied in the field of preparation of nano-silicon array negative electrode materials, can solve problems that are difficult to meet practical requirements, and achieve easy control of microscopic shape and size, excellent rate performance, and good cycle ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Under vigorous stirring conditions, add 0.5 g of sodium silicate into 20 mL of ethanol and mix evenly, then add 12 mL of 0.1 mol / L citric acid solution dropwise under stirring conditions, and stir until transparent to obtain a precursor solution . Then the precursor solution was poured into 80 mL of ethanol, stirred at room temperature for 20 min, and then allowed to stand for 1 h. The resulting solution was transferred to a reaction kettle, and a stainless steel sheet was placed as a base material. The matrix material was ultrasonically cleaned with acetone for 20 minutes before being put in, then soaked in 1mol / L NaOH solution for 25 minutes, washed with ethanol and water alternately, and dried for later use. Adjust the temperature of the reaction kettle to 180° C. and keep it warm for 12 hours to obtain a silicon dioxide nano-array. The silicon dioxide nano-array and the magnesium powder are kept warm in an argon atmosphere at 650° C. for 4 hours to obtai...

Embodiment 2

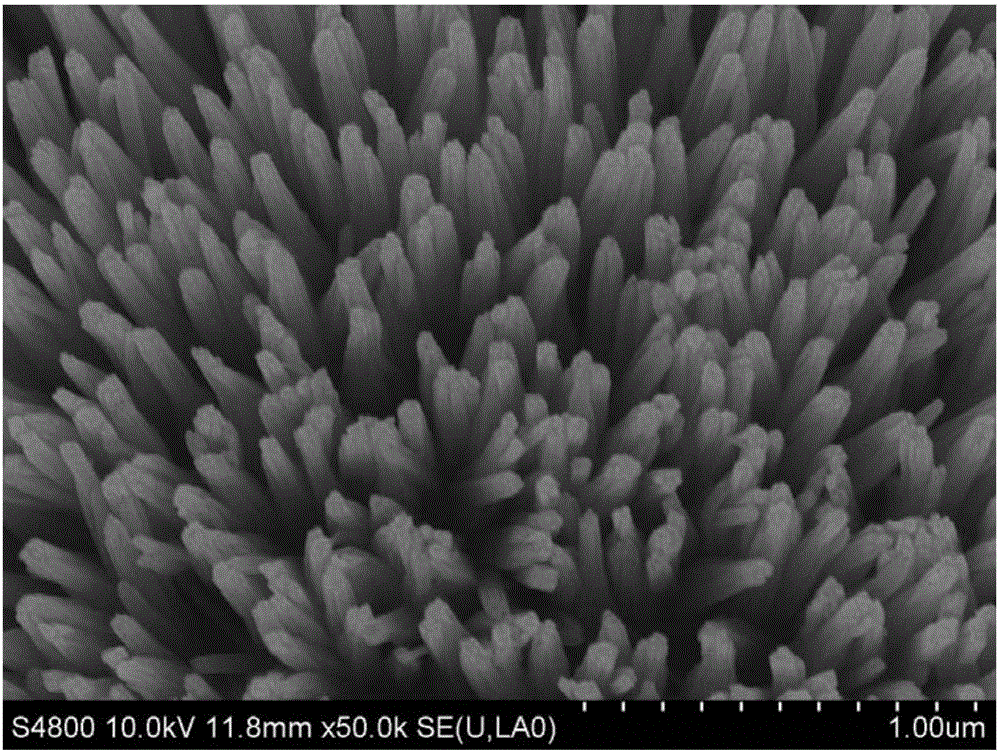

[0026] Example 2: Dissolve ethyl silicate in ethanol to make 45mL of a solution with a concentration of 6wt%, mix this solution with 0.05M citric acid ethanol solution at a volume ratio of 5:2, and transfer it to a hydrothermal reaction kettle . After the hydrolysis reaction took place for 15 minutes, a stainless steel sheet base material was added to the solution, and the base material treatment method was the same as in Example 1. After the hydrolysis reaction is completed, seal the hydrothermal reaction kettle, place it in a muffle furnace and raise the temperature to 220° C. for 5 hours at a rate of 5° C. / min to obtain a silicon dioxide nanoarray. The nano-silicon array anode material for lithium-ion batteries can be obtained by reducing the silicon dioxide nano-array body with zinc powder. Its structural electron microscope diagram can be found in figure 1 .

Embodiment 3

[0027] Example 3: Dissolve ethyl silicate in polyethylene glycol to make 45mL of a solution with a concentration of 5wt%, and then mix it with 0.02mol / L silicon chloride solution at a volume ratio of 3:1, and transfer to In the reaction kettle, 2 mL of 0.2M lactic acid solution was added dropwise under stirring condition to make it hydrolyze. After the hydrolysis reaction occurred for 20 min, the carbon film matrix material was added to the solution. After the hydrolysis reaction, transfer the hydrolysis reaction solution containing the matrix material into a sealed hydrothermal reaction kettle, place it in a muffle furnace and raise the temperature to 160°C for 20 hours at 5°C / min to obtain a silica nano-array, pass the array through Magnesium reduction can be used to prepare the nano-silicon array anode material for lithium-ion batteries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com