System and method for producing environment-friendly building board by using solid wastes

A technology for building panels and environmental protection, which is applied in the field of solid waste resource utilization and environmental protection, can solve problems such as polyformaldehyde and human hazards, and achieve the effects of reducing preparation costs, avoiding waste, and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

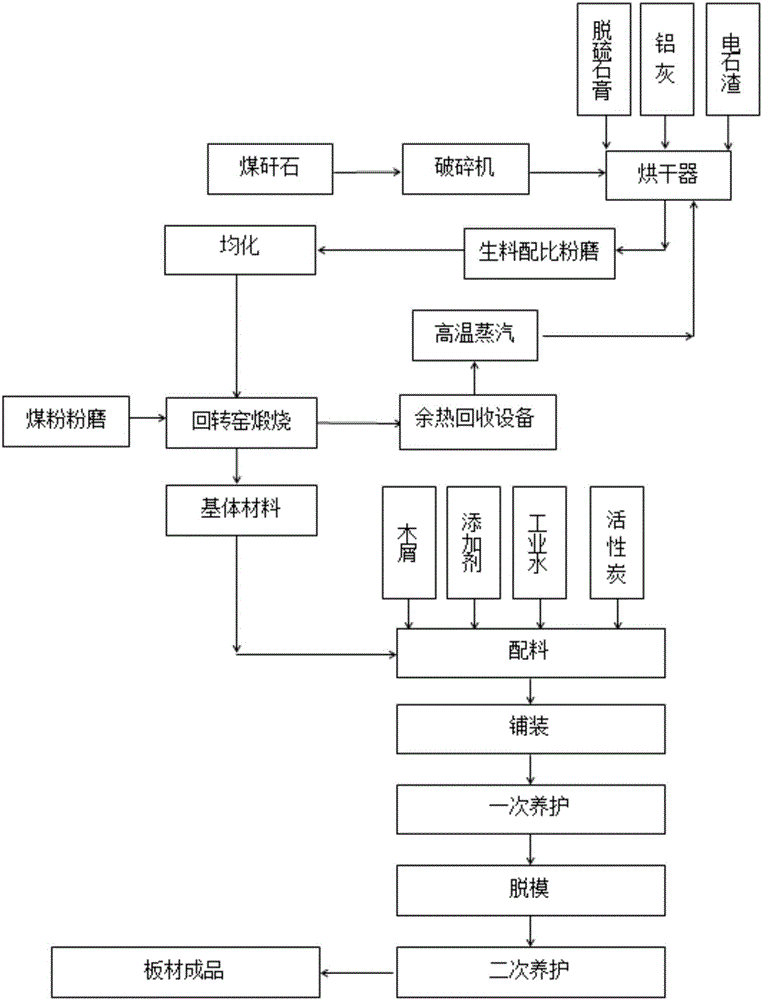

Method used

Image

Examples

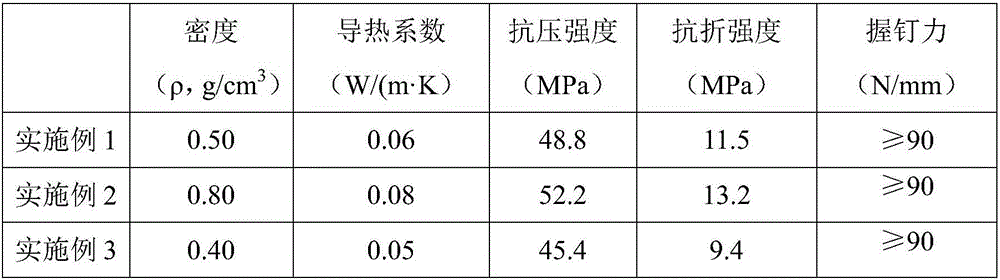

Embodiment 1

[0049] Dry the aluminum ash, calcium carbide slag, and desulfurized gypsum so that the moisture content is less than or equal to 5%. The coal gangue is crushed and mixed with aluminum ash, calcium carbide slag, and desulfurized gypsum. Based on solid matter, coal gangue accounts for 25 parts by weight, desulfurized gypsum accounts for 13 parts by weight, calcium carbide slag accounts for 20 parts by weight, and aluminum ash accounts for 17 parts by weight. . After the components are milled and homogenized, they are transported into a rotary kiln for calcination. The calcination temperature is 1250°C and the calcination time is 70 minutes to obtain the matrix material.

[0050] Take 35 parts by weight of the base material, add 11 parts by weight of activated carbon, 1 part by weight of a mixture of retarder and foaming agent, and then add 30 parts by weight of industrial water to prepare a slurry, and then pave the surface. The thickness of the layer is 1.5 mm.

[0051] Take 20 pa...

Embodiment 2

[0053] Dry the aluminum ash, calcium carbide slag, and desulfurized gypsum so that the moisture content is less than or equal to 5%. The coal gangue is crushed and mixed with aluminum ash, calcium carbide slag, and desulfurized gypsum. In terms of solid matter, coal gangue accounts for 30 parts by weight, desulfurized gypsum accounts for 15 parts by weight, calcium carbide slag accounts for 30 parts by weight, and aluminum ash accounts for 20 parts by weight. . After the components are ground and homogenized, they are transported into a hollow kiln for calcination. The calcination temperature is 1300°C and the calcination time is 70 minutes.

[0054] Take 39 parts by weight of the base material, add 13 parts by weight of activated carbon, 1.1 parts by weight of a mixture of retarder and foaming agent, and then add 34 parts by weight of industrial water to prepare a slurry, and then pave the surface. The thickness of the layer is 1.7 mm.

[0055] Take 35 parts by weight of the bas...

Embodiment 3

[0058] Dry the aluminum ash, calcium carbide slag, and desulfurized gypsum so that the moisture content is less than or equal to 5%. The coal gangue is crushed and mixed with aluminum ash, calcium carbide slag and desulfurized gypsum. In terms of solid matter, coal gangue accounts for 27 parts by weight, desulfurized gypsum accounts for 12 parts by weight, calcium carbide slag accounts for 20 parts by weight, and aluminum ash accounts for 17 parts by weight. . After the components are ground and homogenized, they are transported into a hollow kiln for calcination. The calcination temperature is 1300°C and the calcination time is 80 minutes.

[0059] Take 41 parts by weight of the base material, add 14 parts by weight of activated carbon, 1.6 parts by weight of a mixture of retarder and foaming agent, and then add 30 parts by weight of industrial water to prepare a slurry, and then pave the surface. The thickness of the layer is 1 mm.

[0060] Take 40 parts by weight of the base m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com