Preparation method of biobased water-borne UV (ultraviolet) curing environment-friendly nail polish

A bio-based, nail polish technology, applied in the field of material chemistry, can solve the problems of life and health and environmental threats, not being environmentally friendly, non-toxic, human health hazards, etc., achieving good transparency, fast curing speed, and good adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

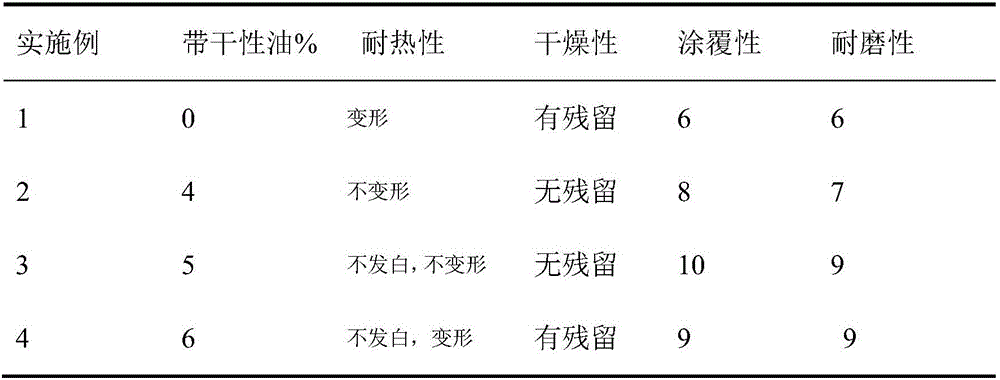

Examples

Embodiment 1

[0034] A preparation method for bio-based water-based UV curing environment-friendly nail polish, comprising the following steps:

[0035] 1) By mass percentage, weigh 8% of oligomer polyol, 6% of dry vegetable oil, 45% of diisocyanate compound, 1.2% of trimethylolpropane, 2% of hydrophilic chain extender, and 4.5% of reactive diluent %, neutralizing salt-forming agent 3%, water-based photoinitiator 0.1% and deionized water 30.2%;

[0036] 2) Add oligomer polyol and drying vegetable oil to the reactor and dehydrate in vacuum at 110° C. for 2 hours to obtain mixture a; add diisocyanate compound, trimethylolpropane, hydrophilic chain extender and solvent to mixture a, React at 60°C for 4 hours to obtain prepolymer b;

[0037] Wherein, the quality of solvent is 33% of the total mass of oligomer polyol, vegetable oil with dryness, diisocyanate compound, trimethylolpropane and hydrophilic chain extender;

[0038] The oligomer polyol is polycaprolactone diol;

[0039] The describ...

Embodiment 2

[0055] A preparation method for bio-based water-based UV curing environment-friendly nail polish, comprising the following steps:

[0056] 1) By mass percentage, weigh 22% of oligomer polyol, 4% of dry vegetable oil, 20% of diisocyanate compound, 2.4% of trimethylolpropane, 10% of hydrophilic chain extender, and 4.5% of reactive diluent %, neutralizing salt-forming agent 5%, water-based photoinitiator 0.3% and deionized water 31.8%;

[0057] 2) Add oligomer polyol and drying vegetable oil to the reactor and dehydrate in vacuum at 120° C. for 1 hour to obtain mixture a; add diisocyanate compound, trimethylolpropane, hydrophilic chain extender and solvent to mixture a, React at 90°C for 1 hour to obtain prepolymer b;

[0058] Wherein, the quality of solvent is 33% of the total mass of oligomer polyol, vegetable oil with dryness, diisocyanate compound, trimethylolpropane and hydrophilic chain extender;

[0059] The oligomer polyol is polytetrahydrofuran diol;

[0060] The desc...

Embodiment 3

[0076] A preparation method for bio-based water-based UV curing environment-friendly nail polish, comprising the following steps:

[0077] 1) By mass percentage, weigh 8% of oligomer polyol, 4.8% of dry vegetable oil, 20% of diisocyanate compound, 2% of trimethylolpropane, 2% of hydrophilic chain extender, and 5% of reactive diluent %, neutralizing salt-forming agent 3%, water-based photoinitiator 0.2% and deionized water 55%;

[0078] 2) Add oligomer polyol and drying vegetable oil to the reactor and dehydrate in vacuum at 110°C for 1.5h to obtain mixture a; add diisocyanate compound, trimethylolpropane, hydrophilic chain extender and solvent to mixture a , reacted at 70°C for 3 hours to obtain prepolymer b;

[0079] Wherein, the quality of solvent is 33% of the total mass of oligomer polyol, vegetable oil with dryness, diisocyanate compound, trimethylolpropane and hydrophilic chain extender;

[0080] The oligomer polyol is a mixture of polycarbonate diol and polyhexamethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com