Tripotassium pentavanadate photocatalyst and bismuth vanadate/tripotassium pentavanadate composite photocatalyst, preparation method and application thereof

A technology of photocatalyst and tripotassium vanadate, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Easy to compound solar energy utilization rate and other issues, to achieve the effect of mild and non-toxic conditions, high yield and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

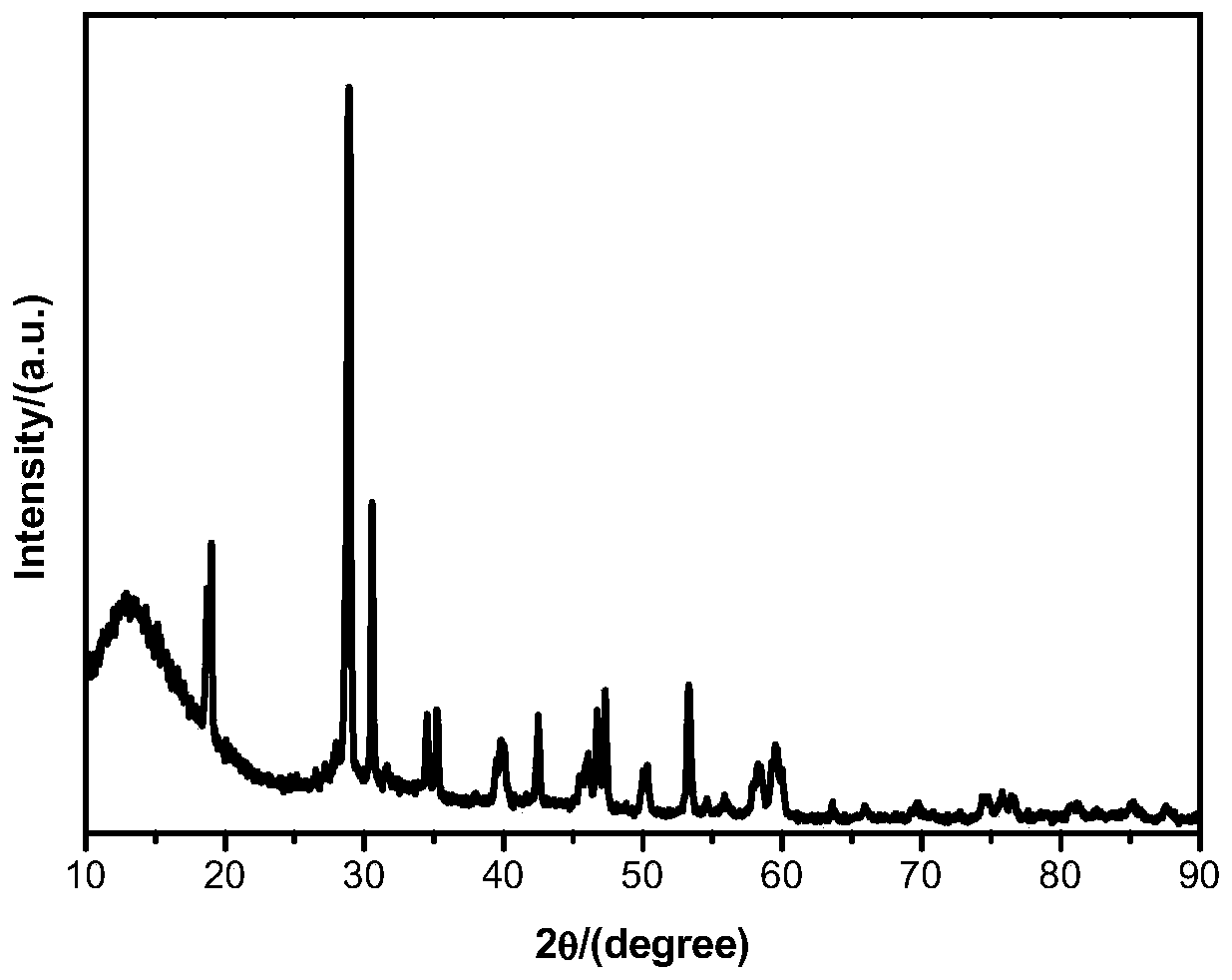

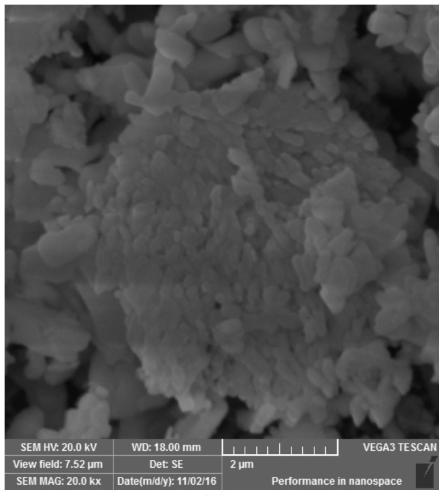

[0040] Example 1: Pure Phase BiVO 4 preparation of

[0041] Weigh 2.5mmol of Bi(NO 3 ) 3 ·5H 2 O and 2.5 mmol of NH 4 VO 3 , were dissolved in 7mL of distilled water and magnetically stirred for 30min, NH 4 VO 3 The suspension was added dropwise with Bi(NO 3 ) 3 ·5H 2 In O, the pH was adjusted to 9 with NaOH, and magnetic stirring was continued for 30 min. Transfer the mixed suspension to the liner of the hydrothermal kettle, add an appropriate amount of distilled water to a filling degree of 80%, heat at 160°C for 12 hours, wash the yellow solid generated by the reaction with distilled water and ethanol several times to neutrality, and Oven drying at 60°C for 6h to obtain pure phase BiVO 4 Photocatalyst, its X-ray powder diffraction pattern (XRD) see figure 1 . The pure phase BiVO prepared in this example 4 Scanning Electron Micrograph (SEM) of the sample see figure 2 . Take BiVO 4 The dosage of the sample is 0.25g / L, and the initial concentration of the met...

Embodiment 2

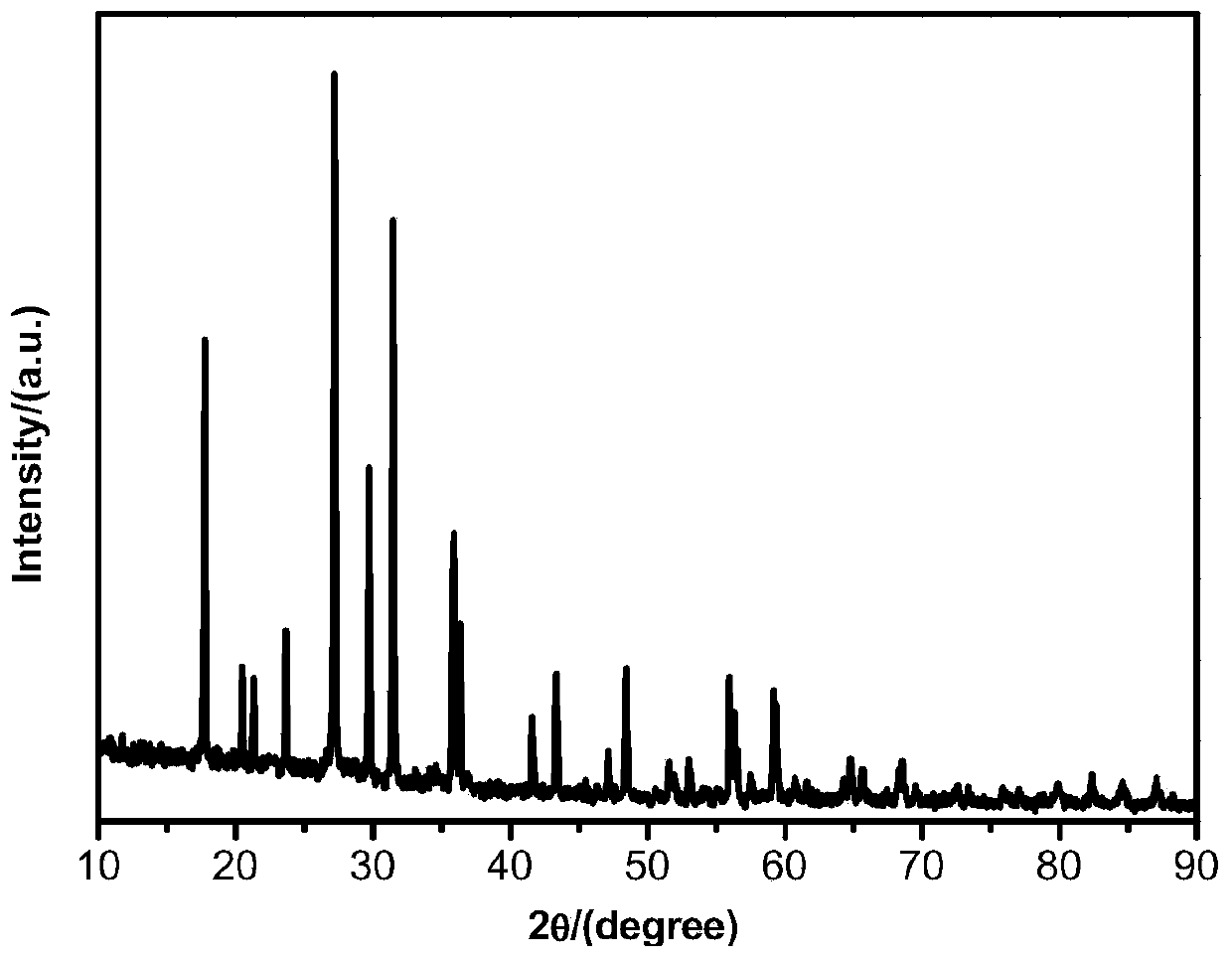

[0042] Example 2: Pure Phase K 3 V 5 o 14 preparation of

[0043] According to chemical formula K 3 V 5 o 14 The stoichiometric ratio of element K and element V in the medium, the raw materials of a certain molar ratio are weighed respectively, the source of K is one or a mixture of potassium carbonate and potassium nitrate, the source of V is vanadium pentoxide and ammonium metavanadate one or a mixture of both. Grind and mix the two reactants evenly, and press into tablets with a powder tablet machine to obtain a tablet mixture. The above flake mixture was calcined under air atmosphere, the calcining temperature was 500°C, the calcining time was 12h, and after natural cooling, it was fully ground to obtain the pure phase K 3 V 5 o 14 Photocatalyst, its X-ray powder diffraction pattern (XRD) see image 3 . The pure phase K prepared in this embodiment 3 V 5 o 14 The scanning electron micrograph (SEM) and the transmission electron micrograph (TEM) of the sample ca...

Embodiment 3

[0045] Example 3: Pure Phase K 3 V 5 o 14 preparation of

[0046] According to chemical formula K 3 V 5 o 14 The stoichiometric ratio of element K and element V in the medium, the raw materials of a certain molar ratio are weighed respectively, the source of K is one or a mixture of potassium carbonate and potassium nitrate, the source of V is vanadium pentoxide and ammonium metavanadate one or a mixture of both. Grind and mix the two reactants evenly, and press into tablets with a powder tablet machine to obtain a tablet mixture. The above flake mixture was calcined under air atmosphere, the calcining temperature was 500°C, the calcining time was 24h, and after natural cooling, it was fully ground to obtain the pure phase K 3 V 5 o 14 catalyst of light. The photocatalytic results showed that, Image 6 It can be seen that the removal rate of methylene blue can reach 88.47% at 75min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com