Super-light ultrathin flexible nano metal/nanofiber composite membrane with X-ray shielding property and preparation method of super-light ultrathin flexible nano metal/nanofiber composite membrane

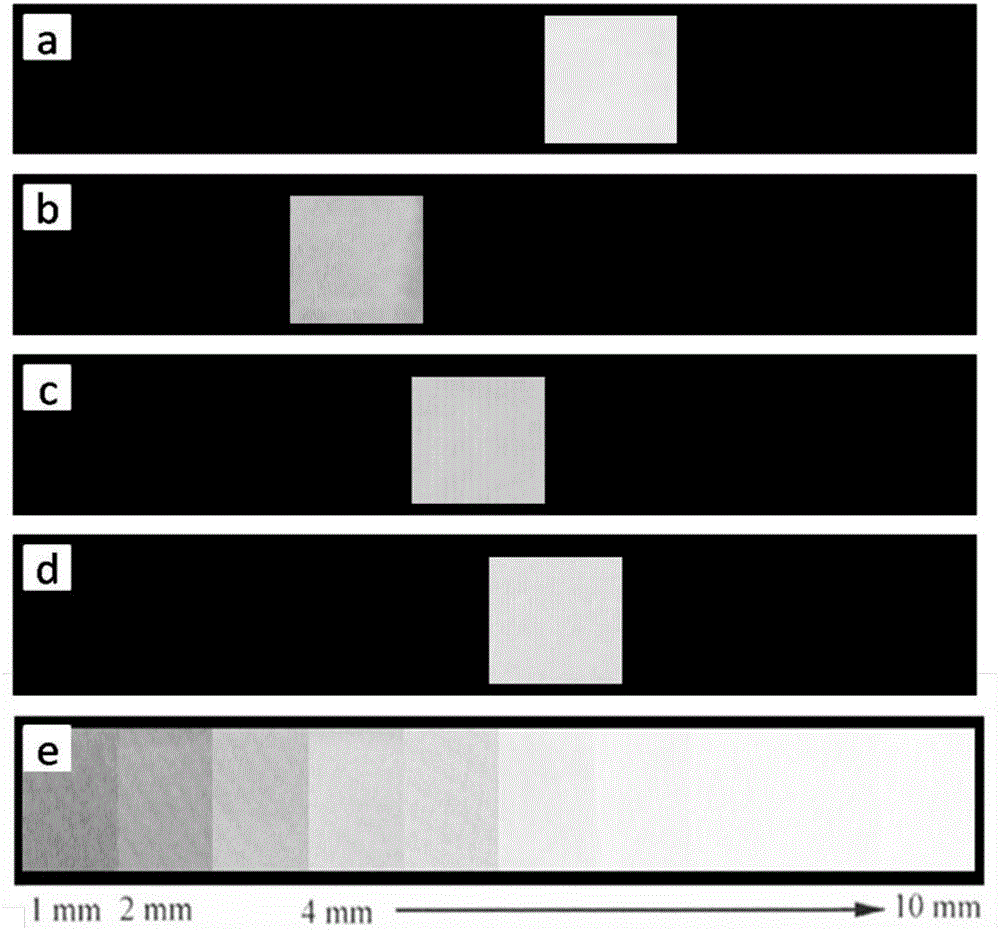

A nanofiber and ray shielding technology, which is applied in the field of X-ray shielding materials, can solve the problems of less research on high-energy ray shielding such as X-rays, and achieve the effect of uniform particle distribution and dense and continuous accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

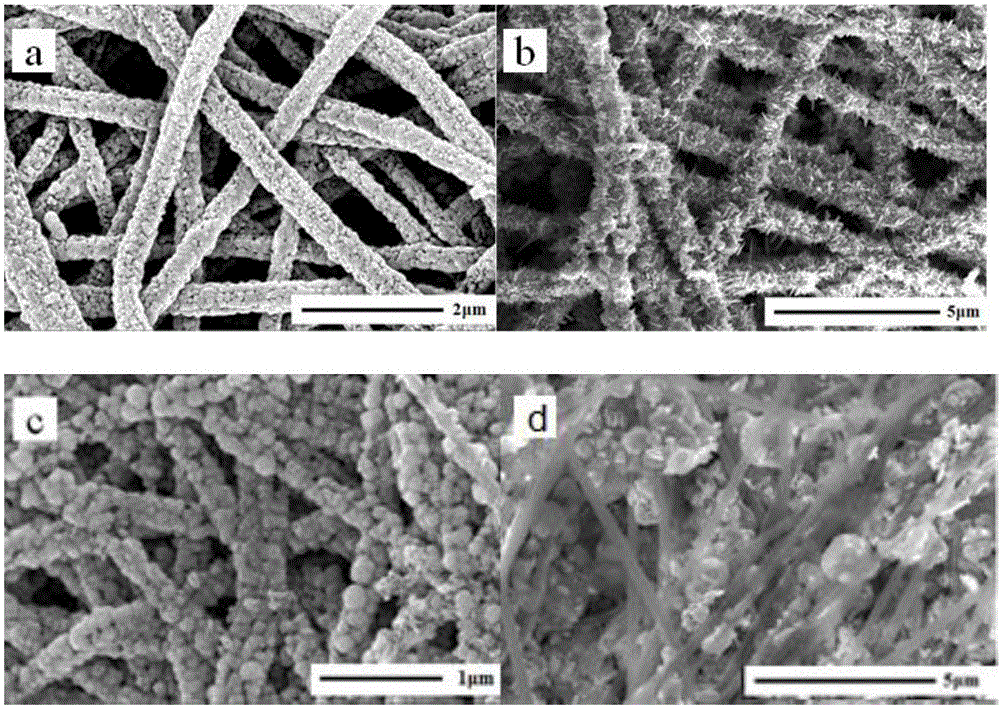

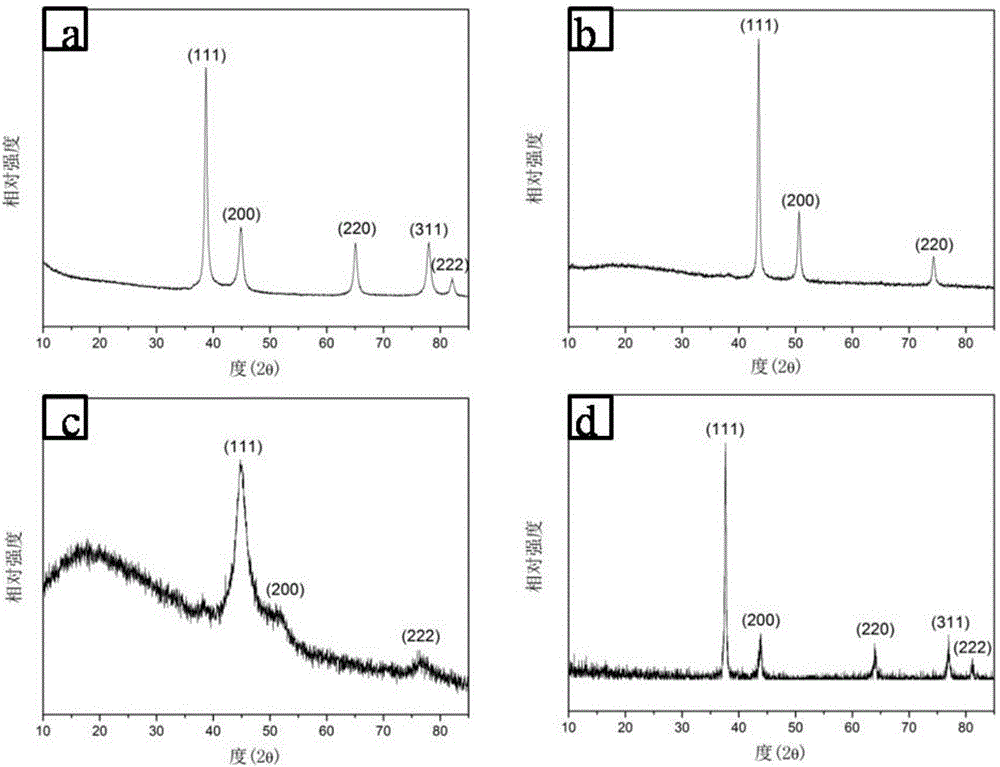

[0049] Step 1, add 0.4g polyacrylonitrile (Mn=80000) and 0.6g polyurethane (Mn=8000) to a conical flask filled with 10g N,N-dimethylformamide (DMF), and place in a water bath at 60°C Heat and magnetically stir for 6 hours until the polymer is completely dissolved, then add 0.2 g of silver nitrate at room temperature and avoid light and stir for 20 hours to obtain a uniform, transparent and stable spinning solution. Move it into the spinneret of the electrospinning device, and carry out electrospinning under the conditions of 15kV, receiving distance of 15cm, spinneret diameter of 1.2mm, ambient temperature of 25°C and humidity of 35%. Acrylonitrile / polyurethane / silver nitrate composite precursor fibers, and the collected precursor fibers were dried in an oven at 65°C for 12 hours.

[0050] Step 2, immerse the composite nanofiber membrane obtained in step 1 in a mixed solution of 6.5g sodium hydroxide and 100mL ethylene glycol, and treat it with 500W microwave for 10s in a micr...

Embodiment 2

[0054] Step 1: Add 0.5g of polyacrylonitrile and 0.5g of polyurethane into a conical flask containing 10g of N,N-dimethylformamide (DMF), heat in a water bath at 55°C and stir magnetically for 6h until the polymer is completely dissolved , and then add 0.25g of copper nitrate, and stir at room temperature for 20h in the dark to obtain a uniform, transparent and stable spinning solution. Move it into the spinning tube, and carry out electrospinning under the conditions of a voltage of 15kV, a receiving distance of 15cm, a spinneret diameter of 1.2mm, an ambient temperature of 25°C and a humidity of 35%, to obtain polyacrylonitrile / Polyurethane / copper nitrate composite precursor fibers, and the collected fibers were dried in an oven at 65°C for 12 hours.

[0055]Step 2, immerse the obtained metal salt / fiber film in a mixed solution of 8g sodium hydroxide and 100mL ethylene glycol, microwave in a microwave oven for 20s, and obtain a seed film with metal particles growing on the ...

Embodiment 3

[0059] Step 1: Add 0.6g of polyacrylonitrile and 0.4g of polyurethane into a conical flask containing 10g of N,N-dimethylformamide (DMF), heat in a water bath at 60°C and stir magnetically for 6h until the polymer is completely dissolved , and then add 0.2g of nickel nitrate at room temperature and avoid light and stir for 20h to obtain a uniform, transparent and stable spinning solution. Move it into an electrospinning device, and perform electrospinning under the conditions of a voltage of 15kV, a receiving distance of 15cm, a spinneret diameter of 1.2mm, an ambient temperature of 25°C, and a humidity of 35%, to obtain polyacrylonitrile / polyurethane / nickel nitrate composite precursor fiber, and put the collected composite fiber into an oven to dry at 65°C for 12h.

[0060] Step 2, immerse the obtained nanofiber membrane in a mixed solution of 8.5g sodium hydroxide and 100mL ethylene glycol, microwave in a microwave oven for 30s, and obtain a seed membrane with metal particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com