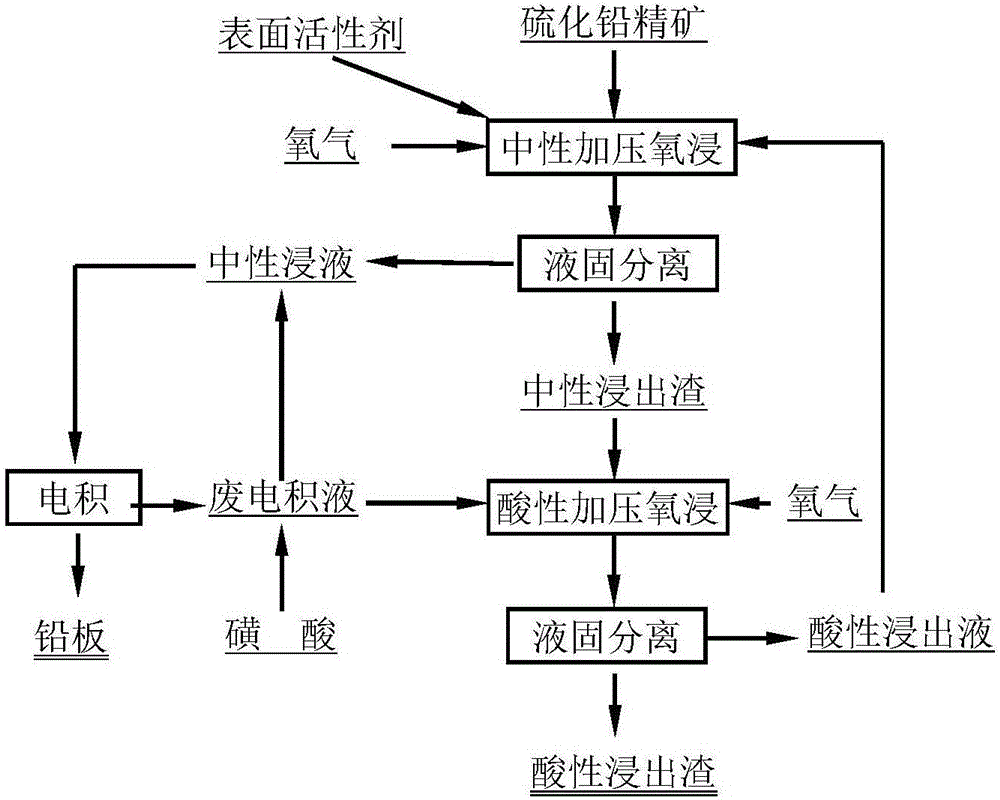

Two-stage counter current oxidative pressure leaching method for lead in lead sulfide concentrate with sulfonic acid solution

A lead sulfide and acid leaching technology, which is applied in the field of non-ferrous metal metallurgy, can solve the problems of serious environmental pollution, high corrosiveness of leaching agents, poor operating environment, etc., and achieve the effects of avoiding environmental pollution, low corrosion, and meeting environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The chemical composition of the lead sulfide concentrate used in the test is shown in Table 1.

[0048] Table 1 Chemical composition of lead sulfide concentrate

[0049] element PbS Fe Ag ingredient / % 48.7117.327.760.0057

[0050] Take 250g of lead sulfide concentrate (its chemical composition is shown in Table 1), add 1200mL of acid leaching solution, its chemical composition is: Pb 2+ 110g / L, the total iron ion concentration is 0.21mol / L, the free methanesulfonic acid concentration is 0.4mol / L; and 0.5g calcium lignosulfonate is added, the inner bladder of the 2000mL autoclave is polytetrafluoroethylene, the stirring speed is 550r / min, oxygen is supplied to maintain a pressure of 0.6MPa, and the reaction is carried out at a temperature of 130°C for 2.5 hours until the pH value of the solution is 5.3, and the total iron ion concentration is less than 4mg / L, then the neutral leachate and the neutral leach residue are separated.

[0051] Add 1200mL waste electrowinning li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com