Super-hydrophobic stainless steel surface coating and preparation method thereof

A surface coating and stainless steel technology, which is applied in the field of superhydrophobic stainless steel surface coating and its preparation, can solve the problems of unfriendly environment, high price, complicated process, etc., and achieve the simple and easy operation of the preparation method, the simple preparation method, and the reduction of process The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Second aspect, the present invention provides a kind of preparation method of superhydrophobic stainless steel surface coating, comprising:

[0044] (1) Provide stainless steel materials and pretreat the stainless steel materials;

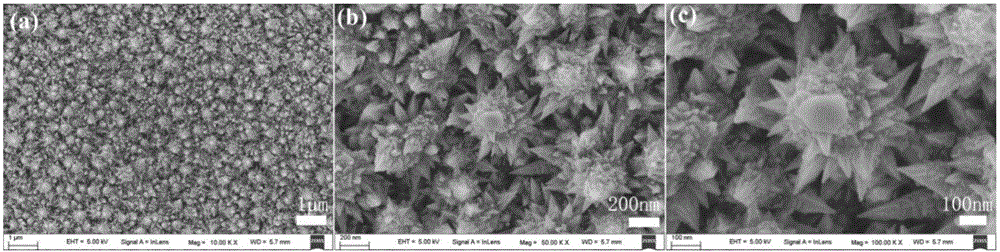

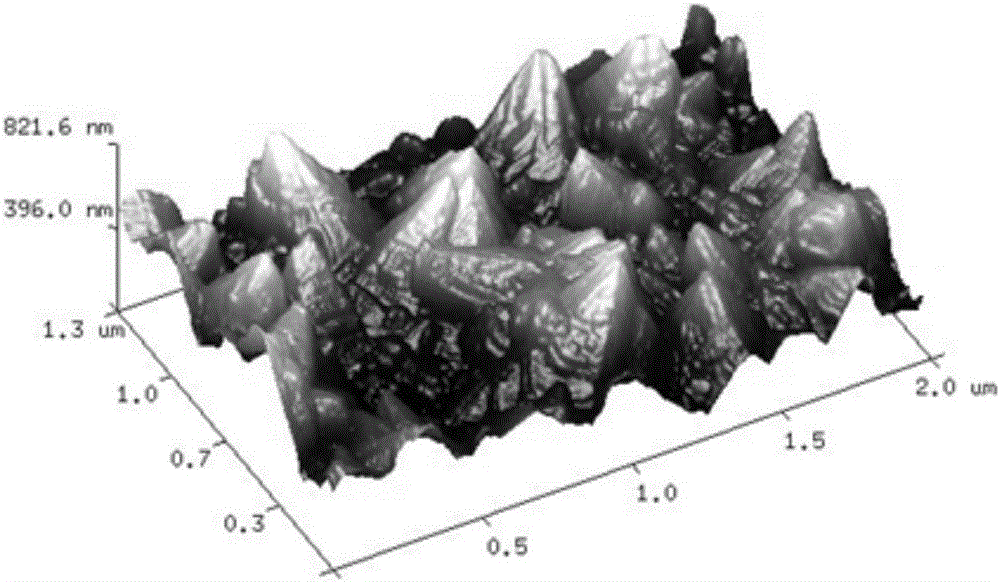

[0045] (2) soak the pretreated stainless steel material as the cathode in the electrodeposition solution containing nickel salt and / or copper salt, use the nickel plate or platinum plate as the anode, and conduct the first electrodeposition on the surface of the stainless steel material, the first The temperature of secondary electrodeposition is 40-80℃, and the current density is 0.1-5A / dm 2 , the electrodeposition time is 50-1000s;

[0046] (3) Electrodeposition is carried out for the second time on the stainless steel material surface that step (2) obtains, and the temperature of electrodeposition for the second time is 40-80 ℃, and the current density of electrodeposition for the second time is higher than the current density of electro...

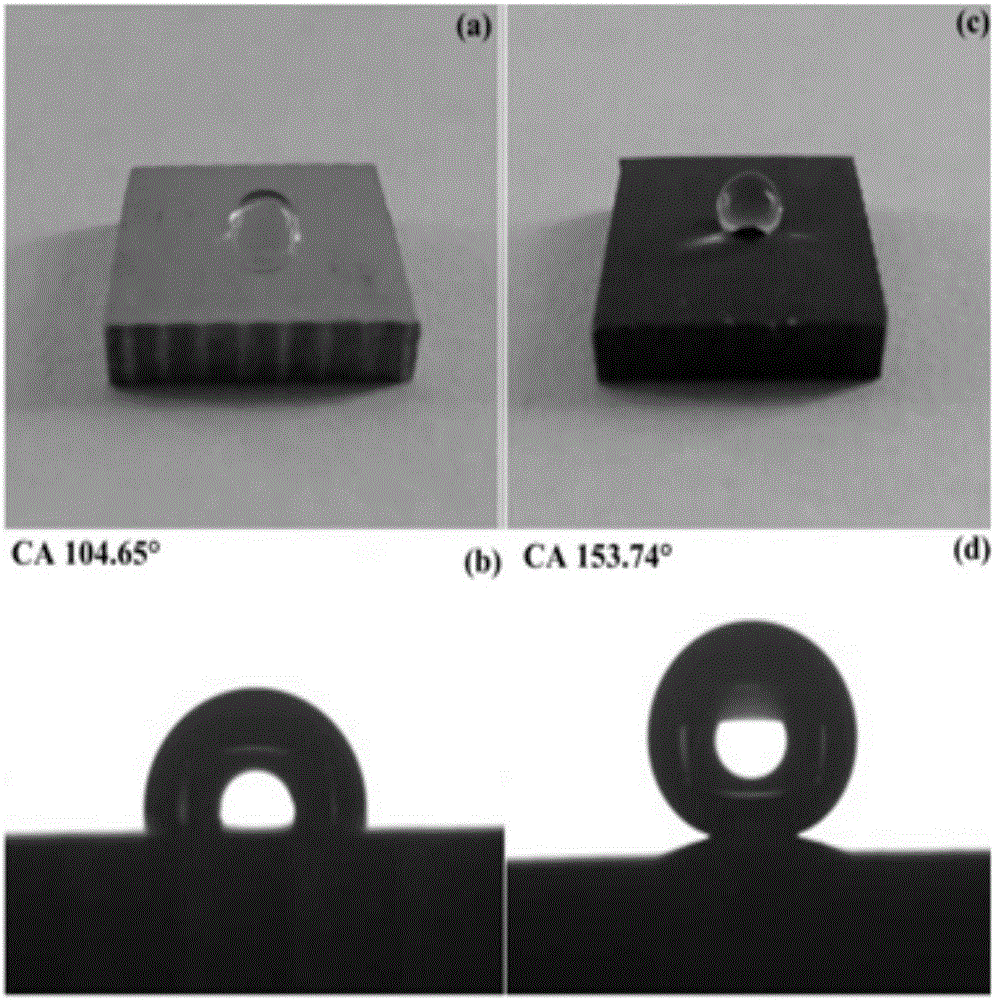

Embodiment 1

[0080] A method for preparing a superhydrophobic stainless steel surface coating, comprising:

[0081] (1) Provide 316L stainless steel as the base material, and use 800#, 1000#, and 2000# water-grinding sandpaper to polish the surface of the 316L stainless steel material in turn. After polishing, clean it with distilled water and ethanol, and then use acetone and ethanol to ultrasonically clean the 316L stainless steel respectively. 20min. Adopt alkaline degreasing agent to carry out degreasing treatment to stainless steel, alkaline degreasing agent comprises concentration and is 10g / L sodium hydroxide, 20g / L sodium carbonate, 10g / L sodium phosphate and 5g / L alkyl polyoxyethylene ether, The oil removal temperature is 70°C, and the oil removal time is 20 minutes. Then use pickling activation solution to carry out pickling activation treatment. The pickling activation solution includes 5mL / L hydrochloric acid (35%), 5mL / L acetic acid (99.3%) and 5mL / L phosphoric acid (85.0%). ...

Embodiment 2

[0087]A method for preparing a superhydrophobic stainless steel surface coating, comprising:

[0088] (1) Provide 316L stainless steel as the base material, and use 800#, 1000#, and 2000# water-grinding sandpaper to polish the surface of the stainless steel material in turn. After polishing, clean it with distilled water and ethanol, and then use acetone and ethanol to ultrasonically clean the 316L stainless steel for 20 minutes. . Adopt alkaline degreasing agent to carry out degreasing treatment to stainless steel, alkaline degreasing agent includes concentration and is 40g / L sodium hydroxide, 50g / L sodium carbonate, 30g / L sodium phosphate and 10g / L alkyl polyoxyethylene ether, The degreasing temperature is 90°C, and the degreasing time is 5 minutes. Then use pickling activation solution to carry out pickling activation treatment. The pickling activation solution includes 20mL / L hydrochloric acid (35%), 10mL / L acetic acid (99.3%) and 10mL / L phosphoric acid (85.0%). Wash and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com