Photoresist composition and preparation method thereof

A composition and photoresist technology, applied in the field of photolithography, can solve the problems of low utilization rate of photoresist composition, large organic solvent pollution, etc., and achieve good technical adaptability and market prospects, good adhesion performance, excellent Effect of Surface Patterning Ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

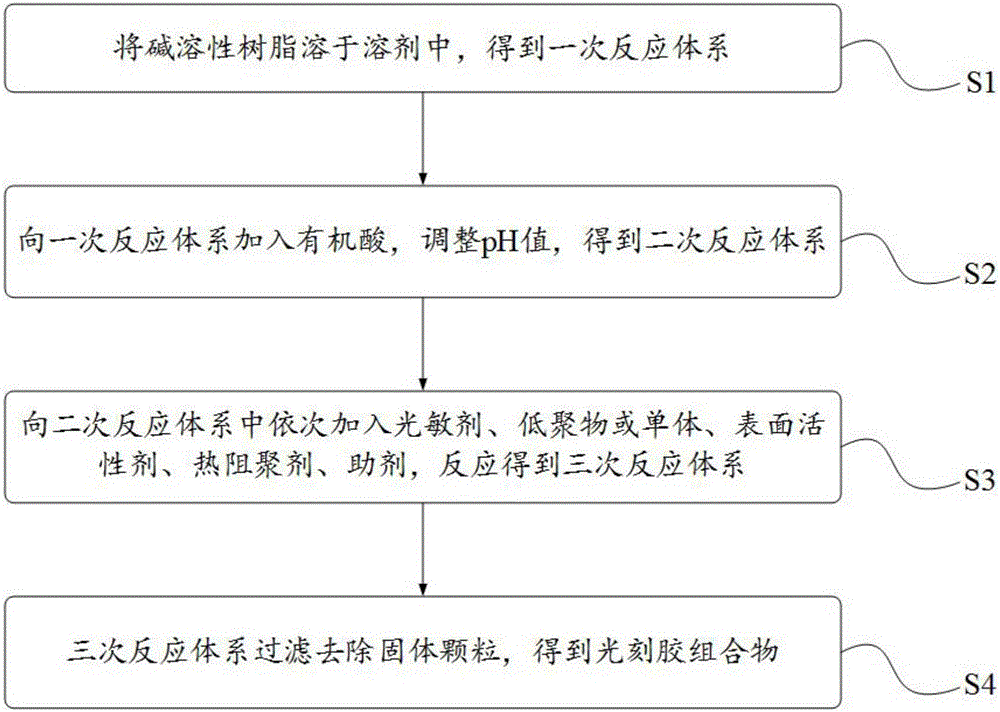

Method used

Image

Examples

Embodiment 1

[0044] The invention provides a photoresist composition, comprising the following components: an alkali-soluble resin with polymerization activity and optical activity; an oligomer or monomer containing at least two unsaturated double bonds and optical activity; a photosensitizer ; Non-ionic or cationic surfactants; Thermal inhibitors; Auxiliaries; Solvents.

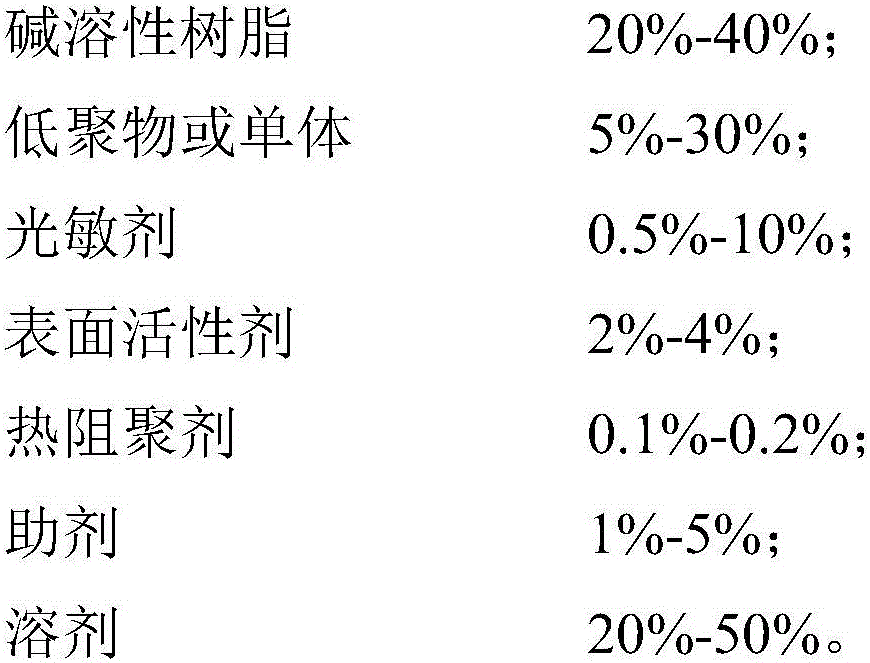

[0045] Further, the composition ratio of each component in the above photoresist composition is as follows according to mass percentage: 20%-40% of alkali-soluble resin; 5%-30% of oligomer or monomer; 0.5%-10% of photosensitizer, Preferably 2%-4%; surfactant 2%-4%; thermal polymerization inhibitor 0.1%-0.2%; auxiliary agent 1%-5%; solvent 20%-50%. The compounds of all components are of electronic grade, free from metal ion impurity contamination.

[0046] In the above solution, the molecular weight of the alkali-soluble resin is 1,000-100,000, preferably 3,000-20,000. The alkali-soluble resin is selected from the group...

Embodiment 2

[0073] The composition and preparation method of the photoresist composition provided in this example and the method of forming a thin film on the surface of the conductive substrate are basically the same as those in Example 1, and only the differences will be described below.

[0074]In this embodiment 2, according to mass percentage, the content of each component in the photoresist composition is as follows: 40% alkali-soluble resin, 22.9% oligomer or monomer, 10% photosensitizer , 2% surfactant, 0.1% thermal polymerization inhibitor, 5% auxiliary agent and 20% solvent.

[0075] Among them, the alkali-soluble resin is preferably a combination of polyurethane acrylate resin and acrylate phenolic resin, and the mass ratio of the two is 1:1.

[0076] The oligomer or monomer is preferably a combination of optically active trimethylolpropane triacrylate and ethoxylated trimethylolpropane triacrylate, and the mass ratio of the two is 1:1.

[0077] The photosensitizer is preferab...

Embodiment 3

[0089] The composition and preparation method of the photoresist composition provided in this example and the method of forming a thin film on the surface of the conductive substrate are basically the same as those in Example 1, and only the differences will be described below.

[0090] In this embodiment 3, according to mass percentage, the content of each component in the photoresist composition is as follows: 40% alkali-soluble resin, 5% oligomer or monomer, 0.5% photosensitizer , 3.3% surfactant, 0.2% thermal polymerization inhibitor, 1% auxiliary agent and 50% solvent.

[0091] Among them, the alkali-soluble resin is preferably a combination of acrylate-modified amino epoxy resin (epoxy equivalent 400-500) and polyether aminoacrylate resin, and the mass ratio of the two is 1:1.

[0092] The oligomer or monomer is preferably a combination of optically active polyester acrylate and silicone-modified acrylate resin, and the mass ratio of the two is 1:1.

[0093] The photose...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com