Environment-friendly fluorine-containing surfactant and preparation method thereof

A surfactant and environmental protection technology, applied in the field of green chemistry, can solve the problems of low yield of reaction products, complex preparation process, difficult decomposition of fluorine-containing surfactants, etc., achieving good environmental protection performance, excellent surface performance, and improved degradation effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

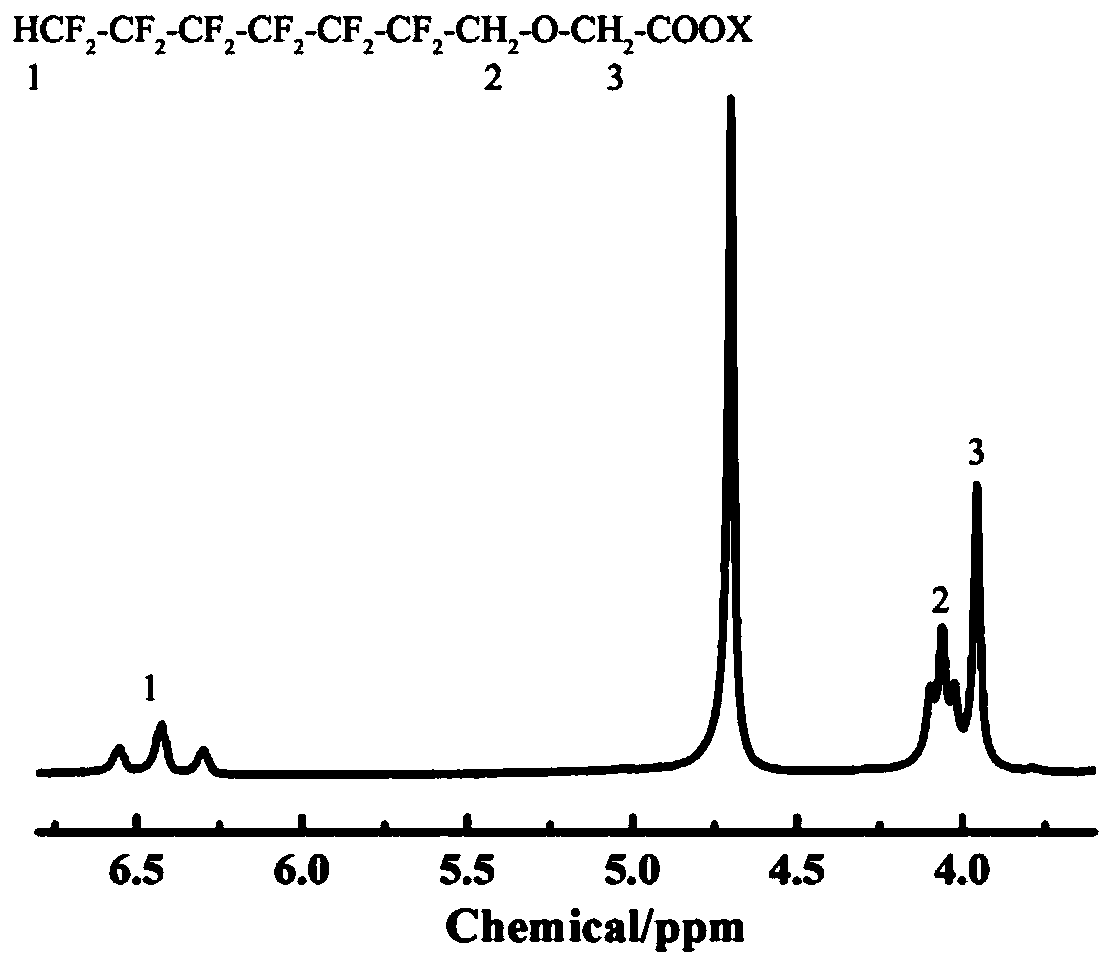

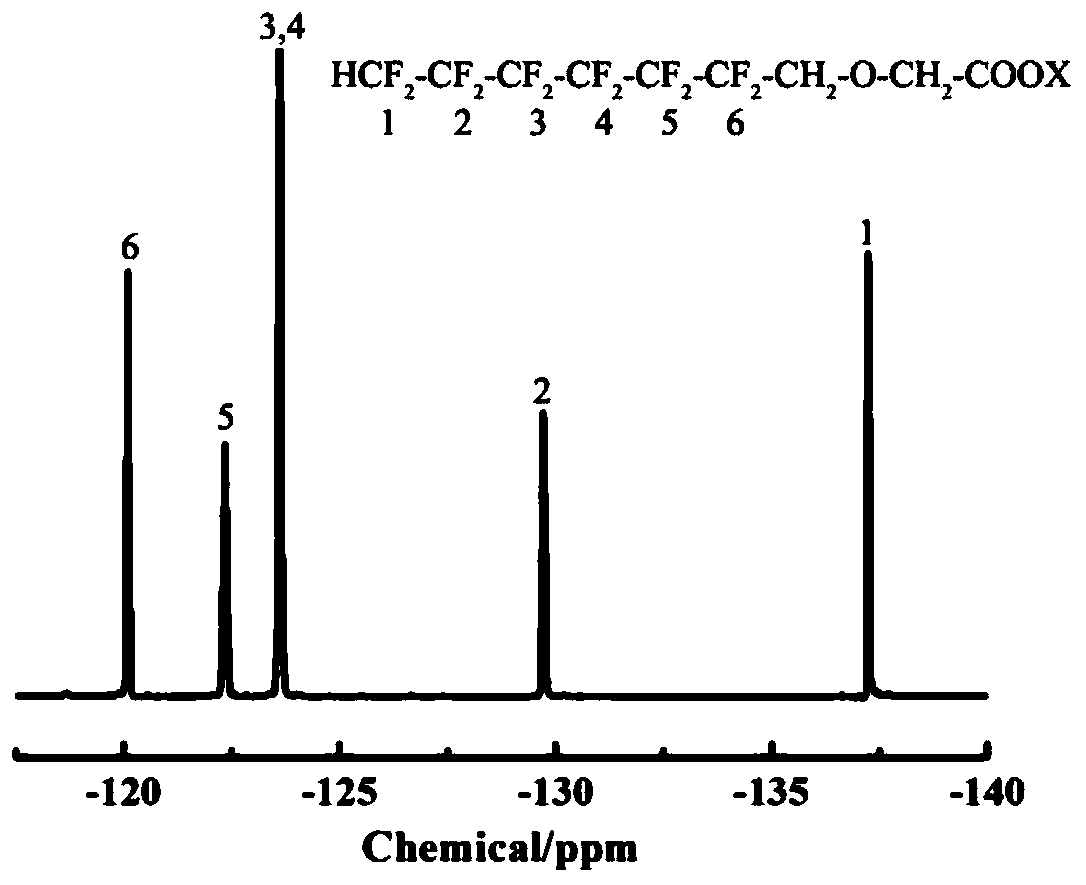

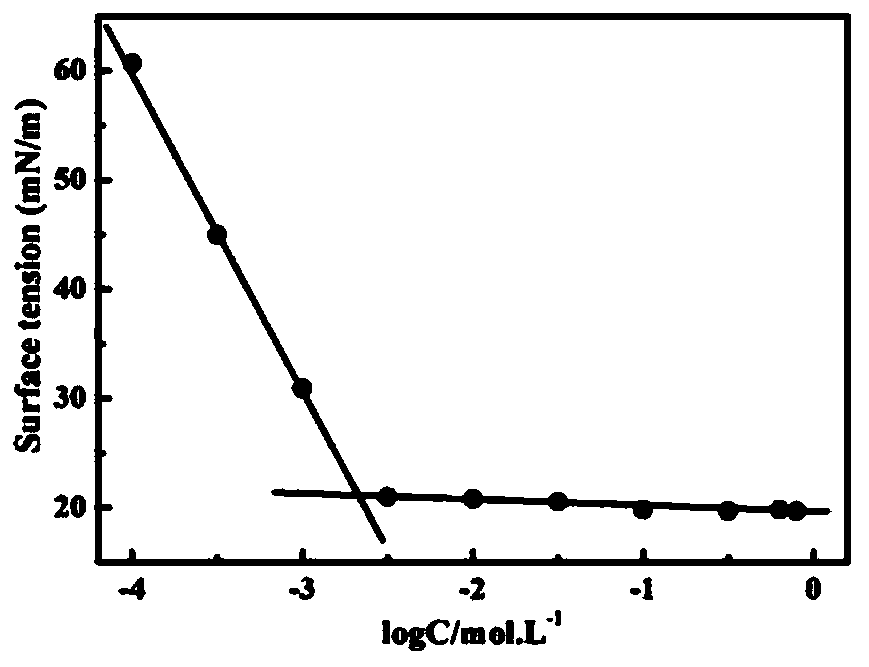

[0049] In a 250mL three-necked flask, add 0.1mol of dodecafluoroheptanol and 50mL of tetrahydrofuran, turn on the magnetic stirring and control the temperature of the flask at -5°C, and slowly pass in nitrogen for 10min. In principle, add 0.1 mol of sodium hydride into the flask, keep stirring at constant temperature for 30 minutes to obtain sodium dodecafluoroheptoxide; then continue to add 10 mL of tetrahydrofuran solution mixed with 0.1 mol of ethyl chloroacetate and tetra-n-butyl 0.4 g of ammonium iodide was reacted for 1 h, and then kept at room temperature (25° C.) for 12 h. The organic phase of the mixture was taken and distilled under reduced pressure to obtain colorless ethyl 1H, 1H, 5H-dodecafluoro-1-heptyloxyacetate;

[0050] Take 0.05mol of 1H,1H,5H-dodecafluoro-1-heptyloxyethyl acetate, 0.048mol of sodium hydroxide and 30mL of absolute ethanol into a 100mL single-necked flask equipped with a reflux device, and heat to 90°C , reacted for 10h, after the reaction wa...

Embodiment 2

[0053] In a 250mL three-necked flask, add 0.05mol of dodecafluoroheptanol and 40mL of tetrahydrofuran, turn on the magnetic stirring and control the temperature of the flask at -5°C, and slowly pass in nitrogen for 10 minutes. In principle, add 0.07 mol of sodium hydride into the flask and keep stirring at constant temperature for 30 minutes to obtain sodium dodecafluoroheptoxide; 0.18 g of trimethylammonium bromide was reacted for 1 h, and then kept at room temperature (25° C.) for 12 h. The organic phase of the mixture was taken and distilled under reduced pressure to obtain colorless ethyl 1H, 1H, 5H-dodecafluoro-1-heptyloxyacetate;

[0054] Take 0.02 mol of 1H, 1H, 5H-dodecafluoro-1-heptyloxyethyl acetate, 0.002 mol of potassium hydroxide and 25 mL of absolute ethanol, add it to a 100 mL single-necked flask equipped with a reflux device, and heat to 90 ℃, reacted for 10 hours, and after the reaction was completed, the mixture was rotary evaporated, and then 10 mL of deion...

Embodiment 3

[0057] In a 250mL three-necked flask, add 0.02mol of dodecafluoroheptanol and 50mL of tetrahydrofuran, turn on the magnetic stirring and control the temperature of the flask at -5°C, and slowly pass in nitrogen for 10 minutes. In principle, add 0.04mol of sodium hydride into the flask,

[0058] Keep stirring at constant temperature for 30 min to obtain sodium dodecafluoroheptoxide, then continue to dropwise add 10 mL of tetrahydrofuran solution mixed with 0.06 mol ethyl chloroacetate and 0.09 g of tetramethylammonium iodide to the flask, react for 1 h, then keep at room temperature ( 25°C) for 12 hours. The organic phase of the mixture was taken and distilled under reduced pressure to obtain colorless ethyl 1H, 1H, 5H-dodecafluoro-1-heptyloxyacetate;

[0059] Take 0.01mol of 1H,1H,5H-dodecafluoro-1-heptyloxyethyl acetate, 0.005mol of ammonia water and 20mL of absolute ethanol into a 100mL single-necked flask equipped with a reflux device, heat to 95°C, After reacting for 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com