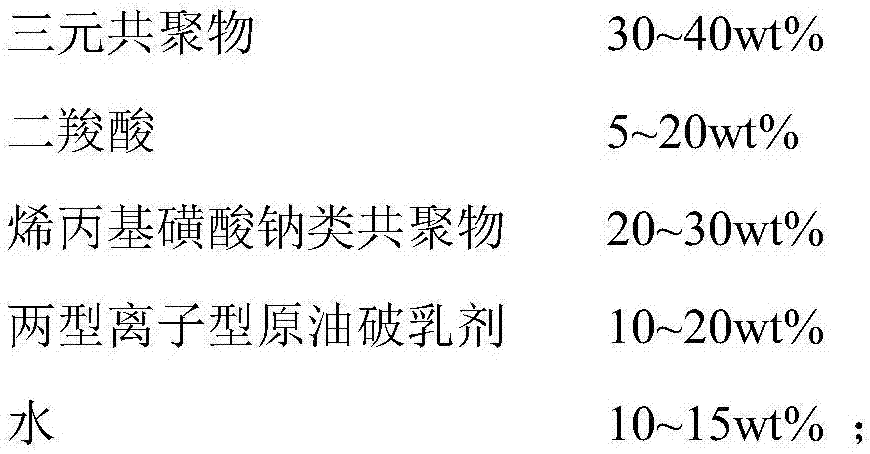

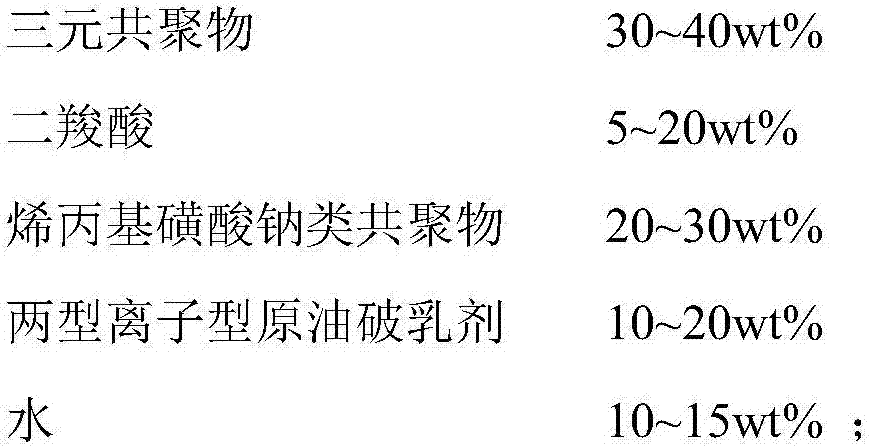

A composite phosphorus-free crude oil metal chelating agent

A metal chelating agent, composite technology, applied in the treatment of hydrocarbon oil, refined hydrocarbon oil, petroleum industry, etc., can solve the problems of low removal efficiency of the precipitation method, corrosion of equipment pipelines, blockage of equipment pipelines, etc. The effect of energy consumption, corrosion prevention, and esterification rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

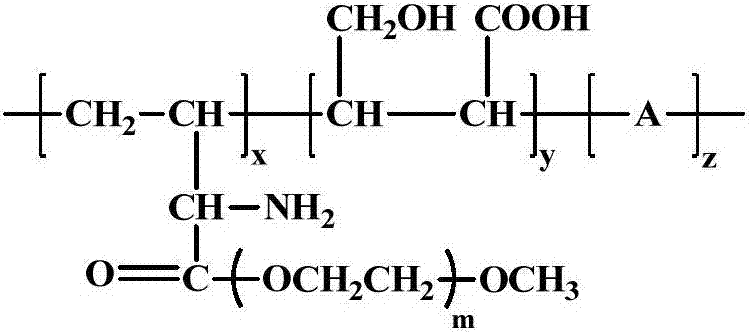

Embodiment 1

[0023] Example 1: Add 10 g of α-aminobutyric acid and 30 g of water into the reaction kettle at 25°C under a nitrogen atmosphere, then adjust the pH with 6 wt% sulfuric acid aqueous solution until the α-aminobutyric acid is completely dissolved, Add 80g of polyethylene glycol monomethyl ether, raise the temperature to 80°C, irradiate with microwave for 10min, and the microwave power is 500W. After the temperature was lowered to 65°C, 1.2g of mercaptoacetic acid, 0.4g of mercaptopropanol and 150g of water were added to the reaction kettle, and the acid ester mixture and 40g of the composite initiator solution were added dropwise at a constant speed, and the dripping was completed within 2.5h. After dripping, adjust the temperature to 80°C to continue the reaction for 3 hours. The ester mixture is formed by mixing 20g of 4-hydroxy-2-butenoic acid, 30g of allyl acetate and 20g of water. The composite initiator solution has a concentration of It is a 2wt% aqueous solution, and aft...

Embodiment 2

[0025] Example 2: Add 15g of α-aminobutyric acid and 50g of water into the reactor at 20°C under a nitrogen atmosphere, then adjust the pH with 8wt% sulfuric acid aqueous solution until the α-aminobutyric acid is completely dissolved, Add 120g of polyethylene glycol monomethyl ether, raise the temperature to 85°C, and irradiate with microwave for 15min with a microwave power of 600W. After lowering the temperature to 60°C, add 2.0g of mercaptopropionic acid, 1.6g of mercaptopropanol and 180g of water into the reaction kettle, add the acid ester mixture and 100g of the composite initiator solution dropwise at a uniform speed, and finish dropping within 2.0h After the drop, the temperature was raised to 75°C to continue the reaction for 3h. The ester mixture was mixed with 35g of 4-hydroxy-2-butenoic acid, 40g of allyl acetoacetate and 18g of water. The composite initiator solution It is an aqueous solution with a concentration of 1.8wt%, and after cooling down to room temperatu...

Embodiment 3

[0027] Example 3: Add 10 g of α-aminobutyrylic acid and 30 g of water into the reaction kettle at 30°C under a nitrogen atmosphere, and then adjust the pH with 3 wt% aqueous sulfuric acid until the α-aminobutyric acid amine is completely dissolved , add 100g of polyethylene glycol monomethyl ether, raise the temperature to 80°C, irradiate with microwave for 15min, the microwave power is 800W, after the temperature is lowered to 65°C, add 2.1g of mercaptopropanol and 180g of water into the reaction kettle, respectively Add the ester mixture and 80g of compound initiator solution dropwise at a constant speed, and finish dropping within 3.5 hours. After dropping, raise the temperature to 80°C and continue the reaction for 6 hours. The acid value mixture is composed of 25g of 4-hydroxy-2-butenoic acid , 45g of methallyl diacetate and 22g of water are mixed, and the composite initiator solution is an aqueous solution with a concentration of 2.5wt%. After being cooled to room tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com