A method of synthesizing nitrogen-containing sulfur-containing multistage porous charcoal through a solid phase process

A solid-phase method, nitrogen-sulfur technology, applied in the preparation/purification of carbon, electrical components, electrochemical generators, etc., can solve the problems of poor controllability of the pore structure and morphology of carbon materials, and achieve good electrochemical performance , the effect of good electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take 0.6 g of melamine and 0.7 g of terephthalaldehyde, grind and mix them in a mortar, and at the same time, take 0.6 g of lithium oxide, add it to the above solid mixture, and grind for 30 minutes. The solid mixture was kept under an inert atmosphere at 3°C for min -1 Raise the temperature to 150°C, keep the temperature constant for 240min, then raise the temperature to 550°C at the same heating rate, and keep the constant temperature for 240min. The water and ethanol solution (3:1 volume ratio) of hydrochloric acid with a mass concentration of 10% was used for acid washing at 60°C for 24 hours, and then washed with water and dried at 90°C for 24 hours.

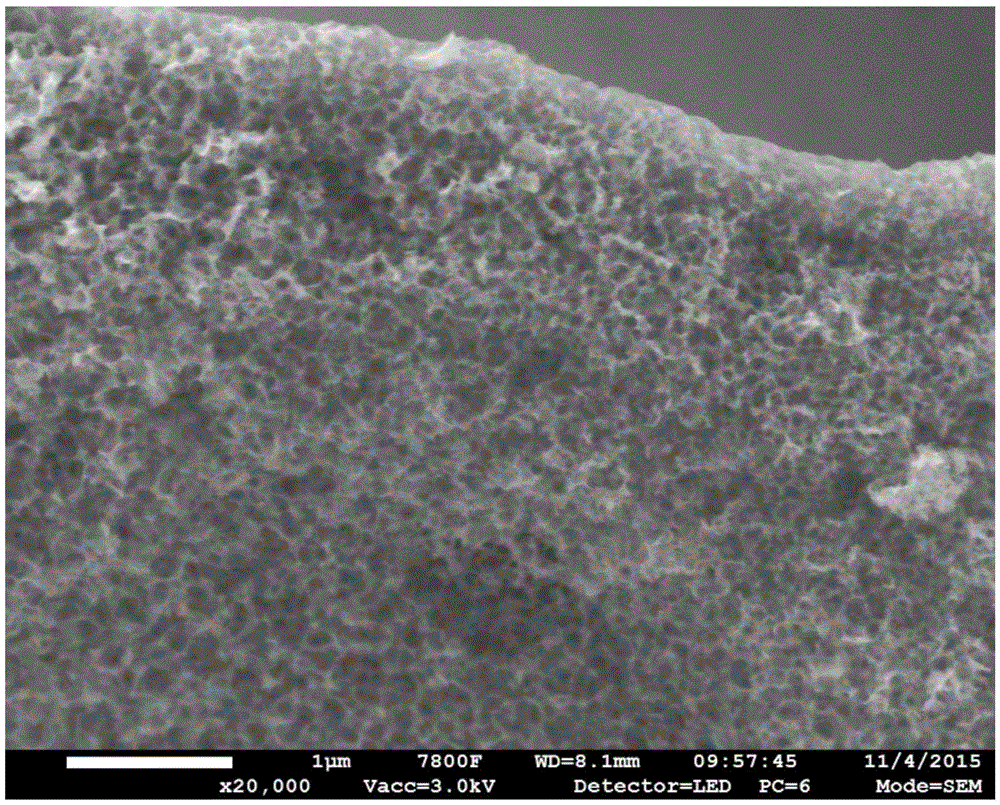

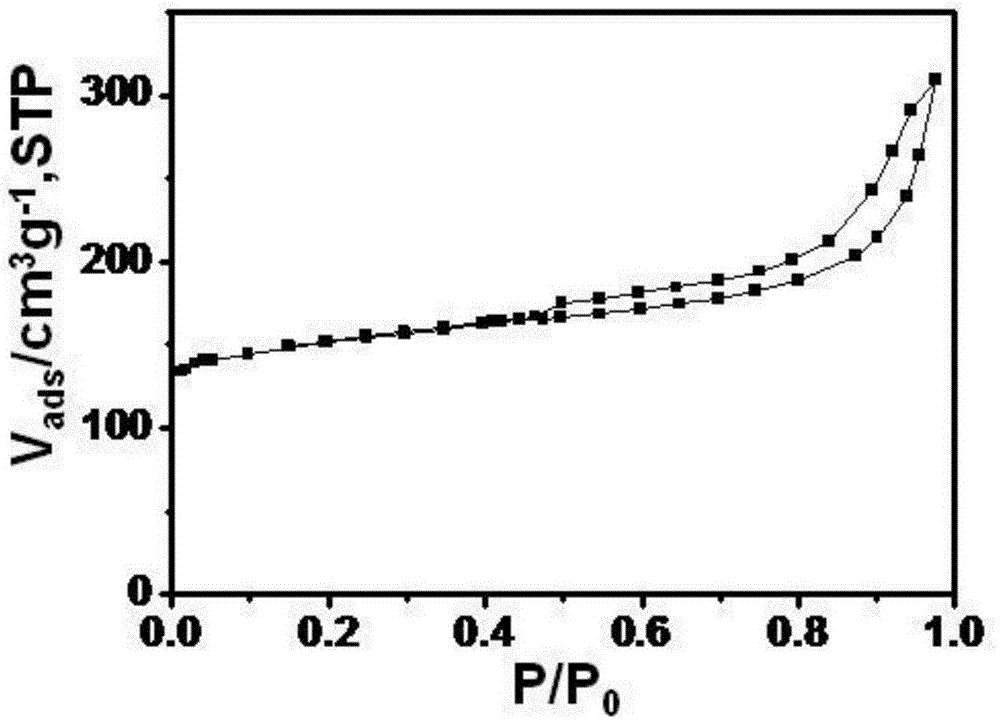

[0025] The scanning electron microscope of present example gained porous carbon material is as figure 1 shown. The sample has a honeycomb-like morphology, and the thickness of the through-hole wall of the honeycomb is about 5nm. The prepared hierarchical porous carbon has macropores of 80-200nm. The resulting ni...

Embodiment 2

[0027] Take 0.6g of melamine and 0.7g of isophthalaldehyde, grind and mix them in a mortar, and at the same time, take 2.1g of lithium oxide, and add it to the above solid mixture, and grind for 30min. The solid mixture was kept under an inert atmosphere at 3°C for min -1 Raise the temperature to 100°C, keep the temperature constant for 240min, then raise the temperature to 600°C at the same heating rate, and keep the constant temperature for 240min. Use 10% hydrochloric acid water and ethanol solution (3:1 volume ratio) to acid wash at 60°C for 24h, then wash with water and dry at 90°C for 24h.

Embodiment 3

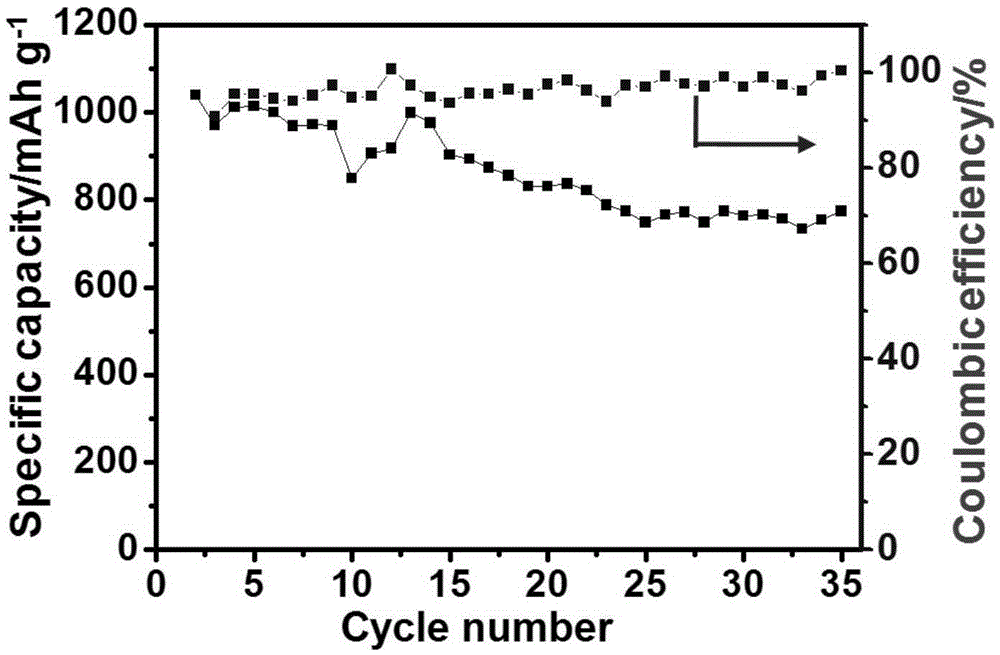

[0029]The bulk nitrogen-containing porous carbon prepared in Example 1 was used as the negative electrode material of the lithium-ion battery. Grind carbon, acetylene black, and PVDF at a mass ratio of 8:1:1, add an appropriate amount of N-methylpyrrolidone, mix well, and coat aluminum foil to prepare pole pieces. The electrode sheet (size 1cm×1cm, about 25-50μm thick) lithium sheet and separator were assembled into a button battery, and its electrochemical performance was tested at a rate current density of 100mA g-1. image 3 is the electrochemical cycling stability curve of the material. The first reversible specific capacity is 1035mAh g -1 , the specific capacity reached 798mAh g after 35 cycles -1 Above, has good cycle stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com