Preparation method of conjugated microporous polymer thin film and application thereof

A polymer film and conjugated microporous technology, which is used in the preparation of conjugated microporous polymer films, can solve the problems of less research on CMPs films, and achieve the effects of high specific surface area, simple equipment requirements and high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A method for preparing a conjugated microporous polymer film is prepared from the above-mentioned polymer precursor TPCz or TPECz.

[0042] Preferably, the preparation method is an electrochemical polymerization method.

[0043] Preferably, the electrochemical polymerization method is cyclic voltammetry.

[0044] Preferably, the cyclic voltammetry is performed in a three-electrode system, and the three electrodes include a working electrode, a counter electrode and a reference electrode.

[0045] Preferably, the working electrode is a transparent electrode; the counter electrode is a noble metal, titanium or graphite electrode; the reference electrode is a silver-silver ion electrode, a silver-silver chloride electrode or a saturated calomel electrode; further preferably, the The working electrode is ITO; the counter electrode is titanium; the reference electrode is silver-silver ion electrode.

[0046] The electrolyte in the system includes the above-mentioned polyme...

example 1

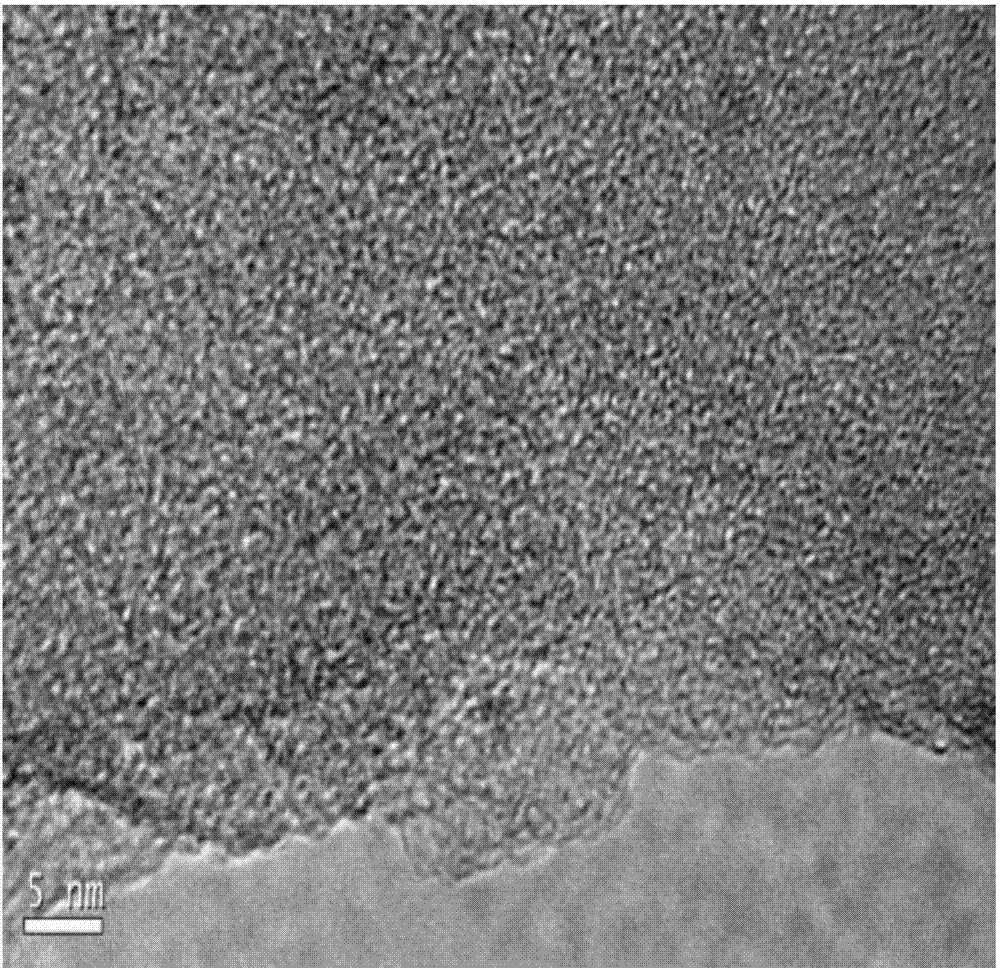

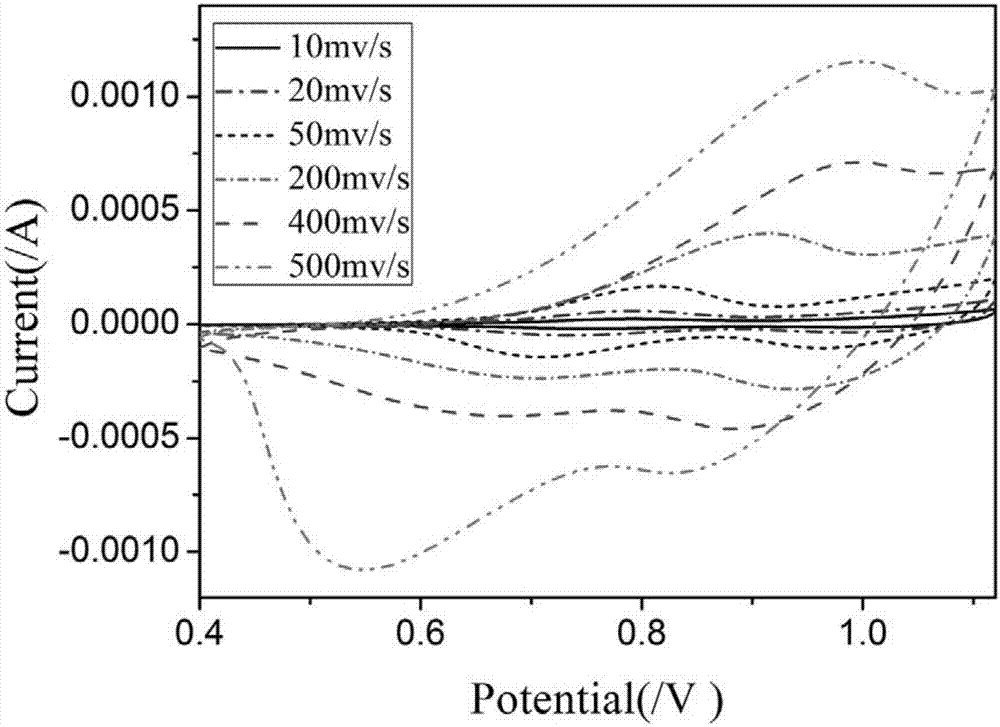

[0051] Example 1 (preparation and application of conjugated microporous polymer film TPCz-CMPs):

[0052] Electrochemical polymerization of TPCz was performed on a CHI 660D electrochemical workstation (Shanghai Chenhua Instrument Co., Ltd.) by cyclic voltammetry.

[0053] A three-electrode system is used, in which ITO glass (1.5cm×1.5cm, working area is 1cm 2 ) is the working electrode, which is cleaned by ultrasonic cleaning with distilled water, ITO cleaning solution, acetone, and isopropanol in sequence, and each solvent is ultrasonically washed 3 times, each time for 20 minutes; titanium sheet (1.5cm×3cm) is used as the counter electrode, after being polished by sandpaper, Then wash it with acetone, absolute ethanol, and distilled water in turn, and dry it for later use; Ag / Ag + The electrode (Shanghai Chenhua Scientific Instrument Co., Ltd.) was used as the reference electrode.

[0054] The composition of the electrolyte: the concentration of the polymeric precursor TPC...

example 2

[0059] Example 2 (preparation and application of conjugated microporous polymer film TPECz-CMPs):

[0060] Electrochemical polymerization of TPECz was performed on a CHI 660D electrochemical workstation (Shanghai Chenhua Instrument Co., Ltd.) by cyclic voltammetry.

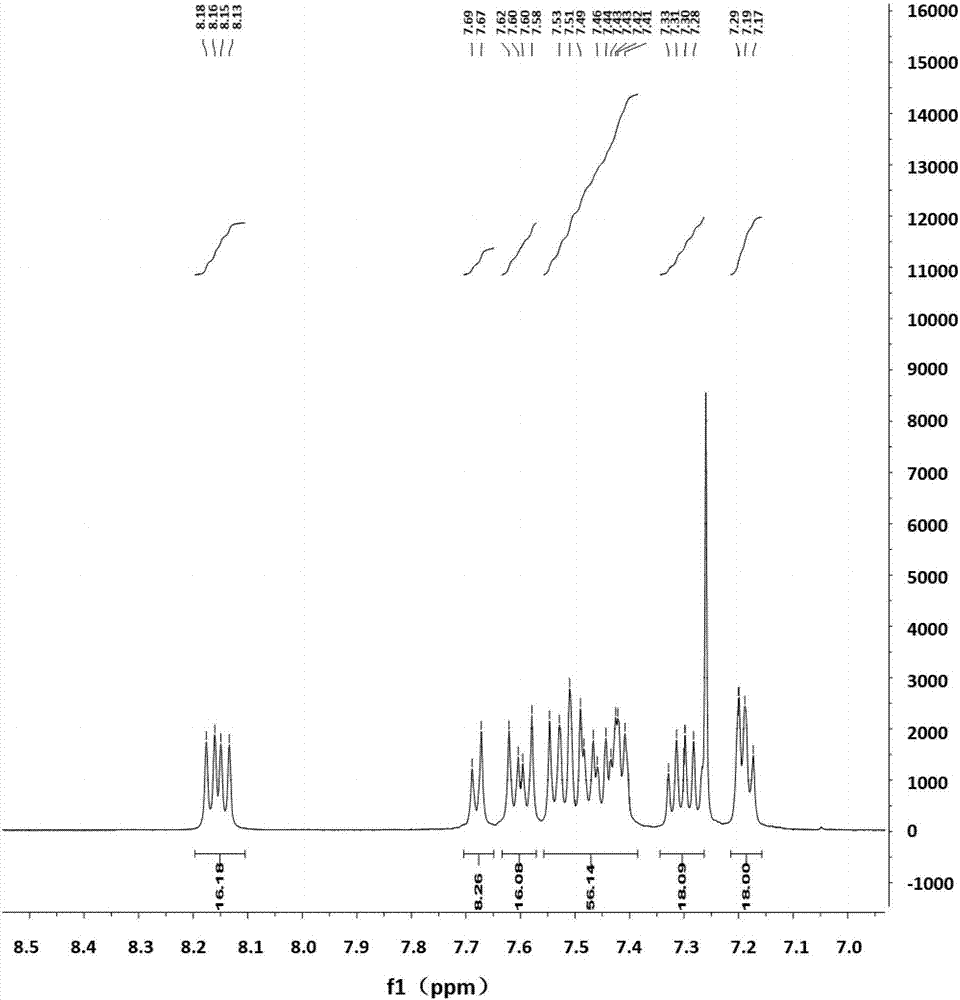

[0061] The synthetic route of the polymeric precursor TPECz used is as follows:

[0062]

[0063] React carbazole and difluorobenzophenone in a DMF solution at 60°C for 12-24h to obtain compound 1 through coupling reaction; use p-bromotoluene and triethyl phosphite to react at 140°C to obtain intermediate product 2 ; Dissolve intermediate 2 in THF, add t-BuOK, then add compound 1, Wittig-Horner reaction occurs at 28°C, react for 12h, and obtain compound 3; use compound 3, borate, KOAC and Pd (dpdf) Cl 2 , then add dioxane to dissolve it, raise the temperature to 75°C, and react for 12 hours to obtain compound 4; the intermediate product is synthesized by Murry reaction, dibromobenzophenone and Zn are dissolve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com