High-tensile-strength environmentally-friendly plastic masterbatch polymer carrier and preparation method thereof

A high tensile strength, environmentally friendly plastic technology, applied in the field of polymer materials, can solve the problems of low mechanical strength, fast degradation, difficult processing, etc., to achieve the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

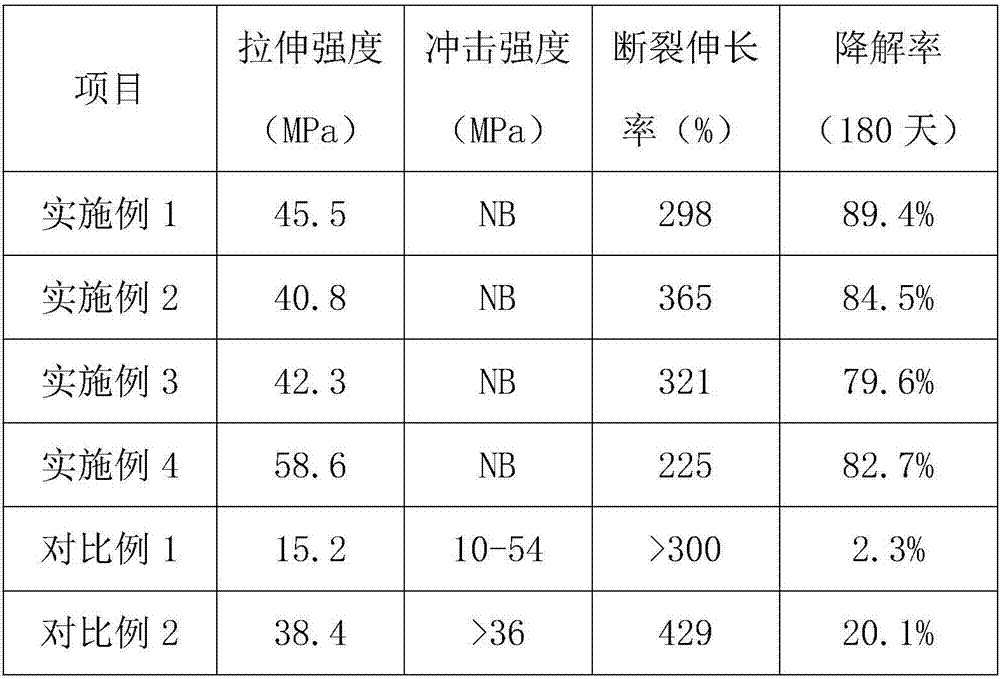

Examples

Embodiment 1

[0025] Add a certain proportion of 105mol ethylene glycol, 50mol terephthalic acid, and 30mol adipic acid into the reaction kettle, naturally raise the temperature to 80°C-90°C, add 0.3‰ nickel acetate and dibutyltin compound, and gradually raise the temperature to 180°C Esterification reaction, until the reaction is complete, the acid value at this time is 11.9mg / g; then add 0.6‰guanidinoacetic acid and 1‰1010 and 626 compound, step up the temperature to 240°C, and carry out the vacuum polycondensation reaction for 2.5 hours, that is Polymer PEAT can be obtained;

[0026] In this embodiment, the nickel acetate and dibutyltin complex is firstly dispersed evenly with toluene, then sodium hydroxide is added as a catalyst, and then ethylenediaminetetraacetic acid solution is slowly added to carry out a high-temperature reflux reaction for 5 hours. The EDTA chelate of metal nickel is synthesized, so the surface area of the catalyst can be effectively increased, thereby increasin...

Embodiment 2

[0035] Add a certain proportion of 135mol ethylene glycol, 50mol terephthalic acid, and 50mol adipic acid into the reaction kettle, and naturally raise the temperature to 80°C-90°C, add 0.4‰ zinc acetate and stannous octoate complex, and gradually raise the temperature to 180°C Carry out esterification reaction at ℃ until the reaction is complete. At this time, the acid value is 11.7mg / g; then add 0.4‰guanidinoacetic acid and 0.8‰1010 and 626 compound, step up the temperature to 240℃, and carry out vacuum condensation polymerization for 2.5 hours , the polymer PEAT can be obtained;

[0036] Accurately weigh PEAT60.25%, PLA5%, shellac resin HY4%, PPC10%, rosin resin TF-100 1%, starch 4%, multilayer graphene 15%, GMA 0.2%, 1098 0.1%, NPPN-631 0.1%, tetraethoxysilane 0.25%, triazine 0.1%, PEAT, shellac resin, rosin resin, multi-layer graphene and compatibilizer are mixed and reacted first, and then all substances are mixed at high speed in a high-mix mixer Mix well and set aside...

Embodiment 3

[0040] Add a certain proportion of 155mol ethylene glycol, 40mol terephthalic acid, and 80mol adipic acid to the reaction kettle, and naturally raise the temperature to 80°C-90°C, add 0.5‰ nickel acetate and stannous octoate complex, and gradually raise the temperature to 180°C Start the esterification reaction at ℃ until the reaction is complete, at this time the acid value is 11.7 mg / g; then add 0.6‰ guanidinoacetic acid and 2‰ 168 and 126 compound, step up the temperature to 245 ℃, and carry out the vacuum polycondensation reaction for 2.5 hours , the polymer PEAT can be obtained;

[0041] Accurately weigh PEAT75%, PLA5%, shellac resin HY3%, PPC8%, rosin resin TF-100 2%, starch 5%, multilayer graphene 0.8%, G-ADR 0.15%, 1010 0.2%, NPPN-631 0.15%, vinyl tris(β-methoxyethoxy)silane 0.42%, o-hydroxybenzophenone 0.3%, first mix PEAT, shellac resin, rosin resin, multi-layer graphene and compatibilizer , and then mix all the materials in a high-mix mixer at a high speed, and set...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com