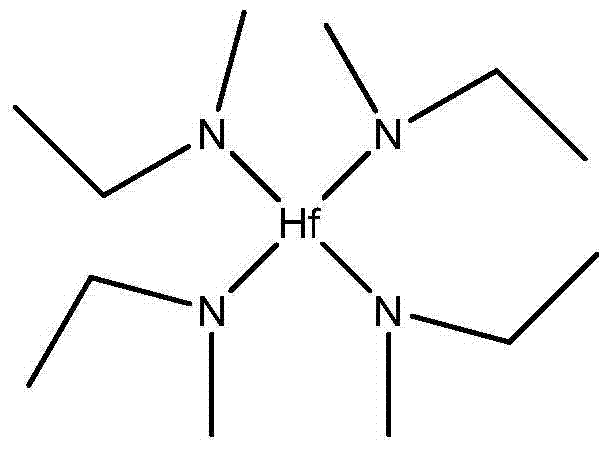

Industrialized production method for tetra(methylethylamino)hafnium

A production method, the technology of ethyl amino, applied in the field of microelectronic material production, can solve the problems of high cost and troublesome operation process, achieve the effects of peaceful reaction process, increase production efficiency and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Under an inert atmosphere, add 50 liters of n-butyllithium n-heptane solution (concentration is 2.5mol / L) in the reactor, and under stirring condition, add 8.1Kg of N-methylethylamine dropwise in the reactor, Control the dropping rate and keep the solution temperature at -20°C, react for 10 hours, then add hafnium tetrachloride 9.1Kg in batches, keep the system temperature at -20°C during the addition, react for 10 hours, and then reflux for 4 hours. After cooling, the solution is transferred to a distiller through a solid-liquid separator, and the pressure is reduced to 50mmHg to distill off the solvent n-heptane, and the temperature is 60°C. The product was then decompressed to 5 mmHg and rectified to distill the product at a temperature of 120° C. to obtain 10.6 Kg of tetrakis(methylethylamino)hafnium (TEMAH) with a yield of 92.8%.

Embodiment 2

[0029] Under an inert atmosphere, add 50 liters of n-butyllithium n-heptane solution (2.5mol / L) into the reaction kettle, and add 7.5Kg of N-methylethylamine dropwise to the reaction kettle under stirring conditions, and control the dropwise Adding temperature is between -10°C, keep system temperature at -10°C after dropwise addition, react for 8 hours, then add hafnium tetrachloride 10.0Kg in batches, maintain system temperature at -15°C during addition, finish adding at -15°C °C for 8 hours, then reflux for 4 hours. After cooling, pass through the solid-liquid separator, transfer to the distiller, first reduce the pressure to 40mmHg to distill out the solvent n-heptane, and the temperature is 50°C. The product was then rectified under reduced pressure of 4 mmHg at a temperature of 130° C. to obtain 10.2 Kg of tetrakis(methylethylamino)hafnium (TEMAH) with a yield of 79.4%.

Embodiment 3

[0031] Under an inert atmosphere, add 50 liters of n-butyllithium n-hexane solution (2.5mol / L) into the reaction kettle, and add 8.1Kg of N-methylethylamine dropwise to the reaction kettle under stirring conditions, and control the dropwise addition Keep the temperature at -15°C during the dropwise addition, keep the system temperature at -15°C, react for 12 hours, then add 9.1Kg of hafnium tetrachloride in batches, maintain the system temperature at -15°C during the addition, and react at -15°C after adding 12 hours, then reflux reaction for 8 hours. After cooling, pass through a solid-liquid separator and transfer to a distiller. First, reduce the pressure to 30mmHg to distill out the solvent n-hexane at a temperature of 50°C. Finally, the product was rectified under a reduced pressure of 30 mmHg at a temperature of 110° C. to obtain 10.2 Kg of tetrakis(methylethylamino) hafnium (TEMAH) with a yield of 87.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com