Novel Mo-To monocrystal oxide nanometer material, preparation thereof and application

A technology of single crystal oxides and nanomaterials, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical/physical processes, etc. The problem of chemical instability and low absorption coefficient has been solved, and the preparation method is simple and fast, the photocatalytic effect is continued, and the cost of raw materials is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Mo-TiO of the present invention 2 The preparation of nanomaterials, more specifically, as an example, may include the following steps:

[0031] First, configure the mixed solution: slowly add a certain amount of Mo salt (such as ammonium molybdate) into the aqueous solution, stir at room temperature to make it fully mixed, and adjust the pH of the solution to between 0 and 3; add an appropriate amount of chelate to the reaction system Mixture (such as hydrofluoric acid), stir evenly;) Slowly add a certain amount of Ti salt (such as tetrabutyl titanate) into the aqueous solution of Mo salt, stir at room temperature to make it fully mixed.

[0032] Then, the nanometer material is obtained after hydrothermal insulation and calcination: the mixed solution is added into a hydrothermal kettle, and the hydrothermal insulation is carried out at a certain temperature for a certain period of time. After the reaction is completed, cool, centrifuge, and dry to obtain a powder samp...

Embodiment 1

[0037] Slowly add 0.3g of ammonium molybdate into 1ml of aqueous solution, stir at room temperature to make it fully mixed, and add a small amount of dilute hydrochloric acid to adjust the pH of the solution to 2. Add 1.5ml of hydrofluoric acid into the reaction system and stir evenly. Slowly add 5ml of tetrabutyl titanate into the aqueous solution of ammonium molybdate, stir at room temperature to make it fully mixed. Add the mixed solution into a hydrothermal kettle and heat it to 150°C for 10h. After the reaction is completed, cool, centrifuge, and dry to obtain a powder sample. The powder sample was calcined at 400 °C for 1 h to remove the surface organic matter and obtain Mo-TiO 2 nanoparticles.

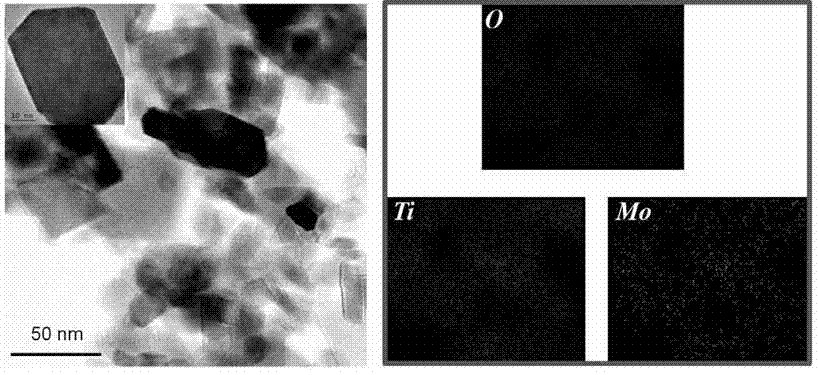

[0038] figure 1 Mo-TiO 2 The transmission electron microscope (TEM) photo and the corresponding element distribution can be seen from the photo: Mo in TiO 2 Evenly distributed on the substrate, and Mo-TiO 2 It is single crystal.

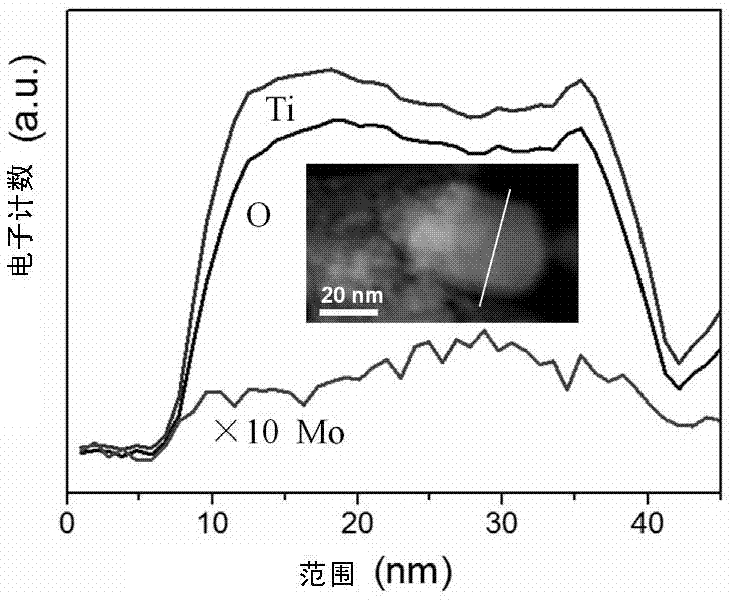

[0039] figure 2 For a single Mo-TiO 2...

Embodiment 2

[0047] Slowly add 0.63g of sodium molybdate into 3ml of aqueous solution, stir at room temperature to make it fully mixed, and add a small amount of dilute hydrochloric acid to adjust the pH of the solution to 0. Add 500 mg of polyvinylpyrrolidone into the reaction system and stir evenly. Slowly add 10ml of titanium isopropoxide into the aqueous solution of ammonium molybdate, stir at room temperature to make it fully mixed. Add the mixed solution into a hydrothermal kettle and heat it to 200°C for 10h. After the reaction is completed, cool, centrifuge, and dry to obtain a powder sample. The powder sample was calcined at 500 °C for 1.5 h to remove the surface organic matter and obtain Mo-TiO 2 nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com