Method for producing acetic acid by utilizing self-assembly conductive biological membrane electrode to reduce carbon dioxide

A technology of biofilm electrode and carbon dioxide, which is applied in the direction of using microorganisms, methods based on microorganisms, biochemical equipment and methods, etc., can solve the problem of poor electrical conductivity of biofilms and the inability of electroautotrophic microorganisms to obtain sufficient and efficient Transfer electrons and other issues to achieve the effect of improving electron transfer rate, strengthening efficiency, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: the domestication of aerobic microorganisms, the specific domestication steps are as follows:

[0029] Add the anaerobic sludge to the solution rich in medium, add a certain amount of inoculum to the pre-passed H 2 , CO 2 The proportion is in the anaerobic bottle of the mixed gas of 80:20, and culture medium is PETC solution, wherein the prescription of PETC solution is: 1g / LNH 4 Cl, 0.1g / L KCl, 0.2g / L MgSO 4 ·7H 2 O, 0.8g / L NaCl, 0.1g / L KH 2 PO 4 ,0.02g / L CaCl 2 ,1g / L NaHCO 3 ,pH=7.0.

[0030] Then add a 2% aqueous solution of methane chloride in a mass ratio, react for 7 days, then insert it into the above-mentioned anaerobic bottle with a 5% inoculum size, react for 5 days, then turn over again, after repeating 3 times, still press 5% of the inoculum amount was reversed, and the reaction time was reduced to 3 days, and then repeated 3 times, and then turned over with 5% of the inoculum amount, and the time was reduced to 1.5 days, and after repe...

Embodiment 2

[0031] Embodiment 2: Preparation of conductive biofilm electrode

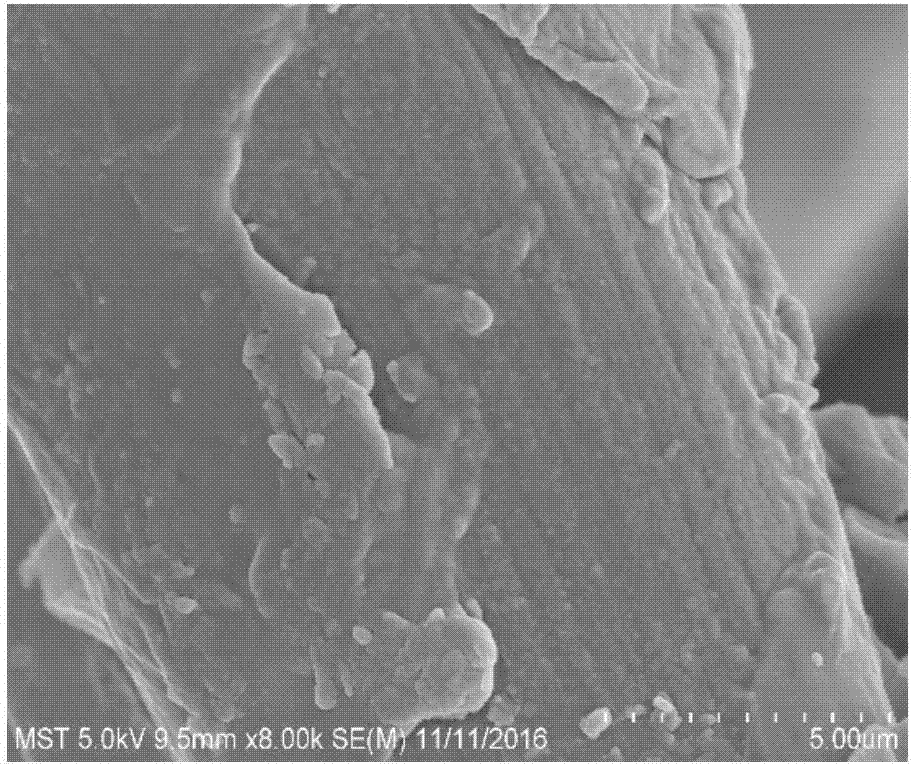

[0032] Put the carbon felt as the electrode into the anaerobic bottle, the cathode solution is PETC solution, and inoculate 5% of the high-efficiency aerobic microorganisms obtained through (1) screening, and react with hydrogen and carbon dioxide (80 / 20, v / v) 7 Two days later, the reaction solution was replaced with a new PETC solution, and 0.5mg / ml of graphene oxide was added, and then H 2 , CO 2 The ratio of hydrogen and carbon dioxide is 80:20. After 5 days of reaction, the solution turns black, and the desired conductive biofilm electrode is obtained. figure 2For the prepared conductive biofilm electrode, it can be seen that the graphene wraps the microorganisms and is well attached to the carbon felt electrode.

Embodiment 3

[0033] Example 3: Bioelectrochemical reduction of carbon dioxide by conductive biofilm electrode to produce acetate

[0034] The specific assembly steps and operation of the bioelectrochemical device are as follows:

[0035] (1) Put the carbon felt anode and the prepared conductive biofilm electrode into the anode chamber and the cathode chamber respectively

[0036] (2) all add the PETC solution among the embodiment 1 in the anode chamber and the cathode chamber, add the potential of-1.05V (relative to silver / silver chloride) with potentiostat between the cathode and the anode, then continuously pass into 100% Carbon dioxide, the reaction temperature is 25°C.

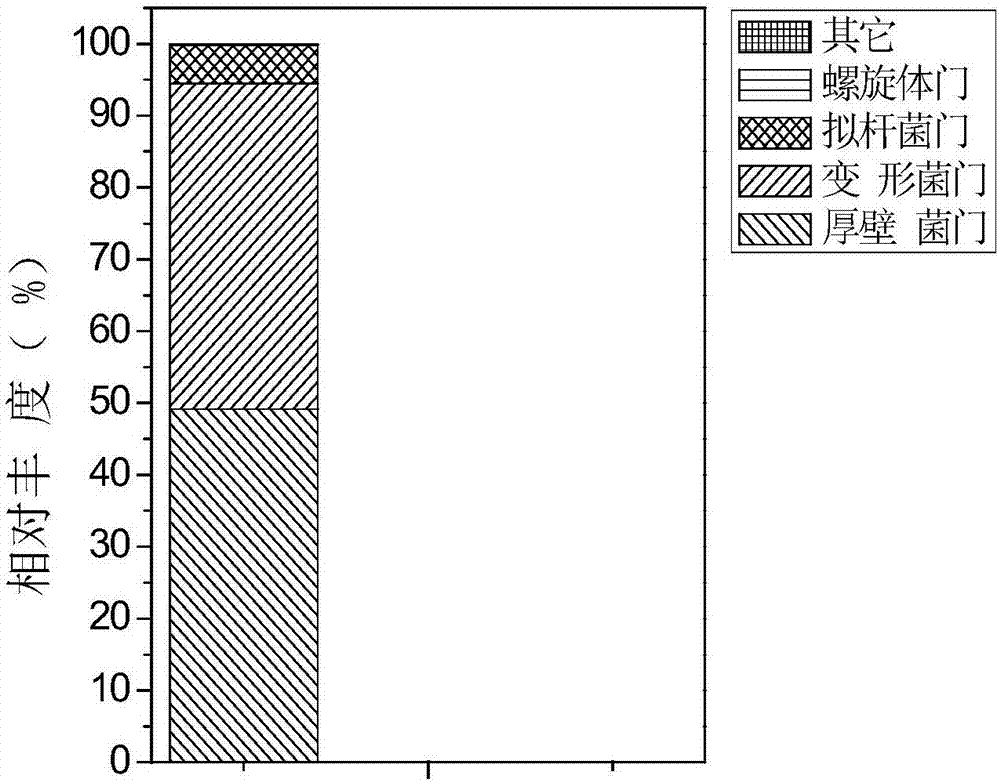

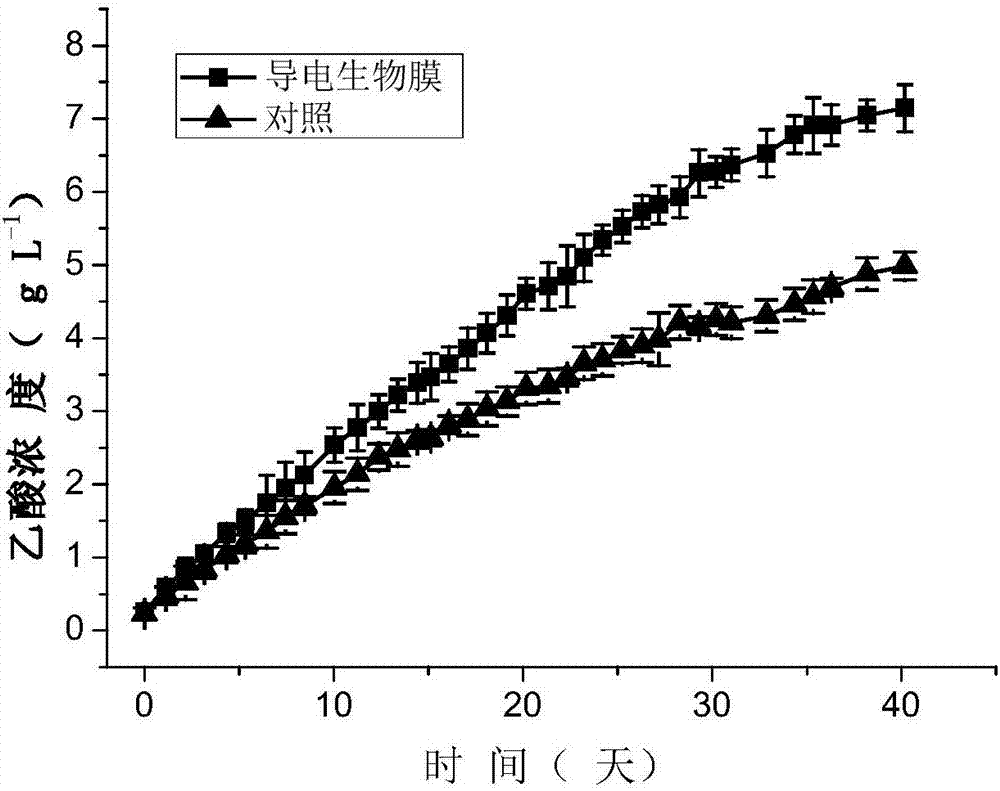

[0037] Taking the carbon felt cathode without adding graphene in the manufacturing process as a control, its preparation method is the same as in Example 2, except that graphene oxide is not added, and all bioelectrochemical systems are continuously operated for 40 days, and samples are taken regularly to measure the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com