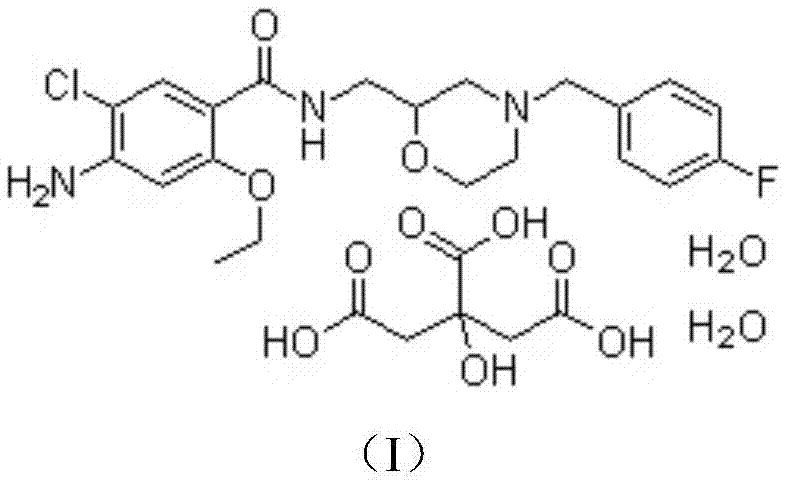

Medicine composition of mosapride citrate and preparation method of same

A technology of mosapride citrate and a composition is applied in the field of pharmaceutical compositions containing mosapride citrate, and achieves the effects of good thermal stability and good masking of bitter taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Embodiment 1 (sample 4)

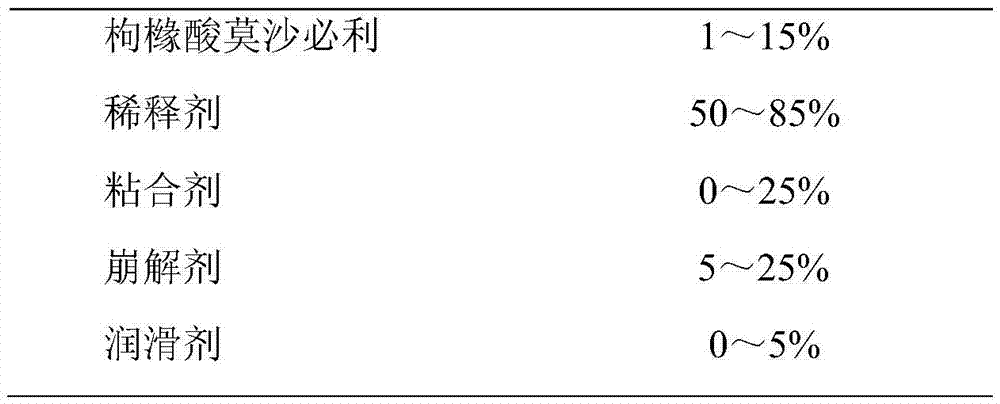

[0077] [Table 7] Chip composition

[0078]

[0079]

[0080] ▲When necessary, use lactose as an adjusting component to change tablet weight.

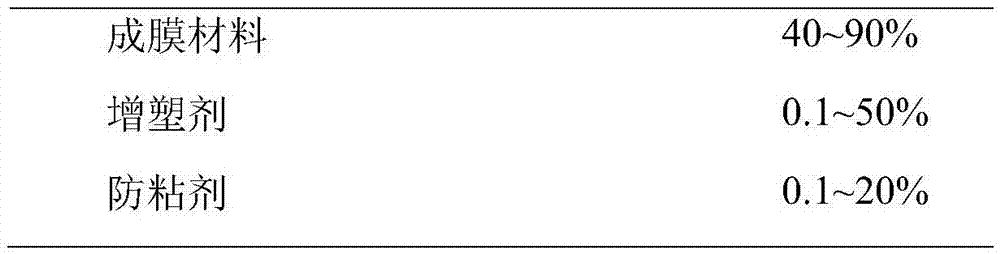

[0081] [Table 8] Composition of film coating aqueous solution

[0082]

[0083] ▲Purified water accounts for about 90% (w / w) of the film coating aqueous solution.

[0084] The plain tablet (core tablet) containing mosapride citrate was prepared according to the composition ratio shown in the above table [7].

[0085] Dissolve 10 g of hypromellose in 40 g of purified water to obtain a binder solution. The prepared binder solution was added to the mixture containing mosapride citrate (5.29g), lactose (51.91g), starch (32.4g) and low-substituted hydroxypropyl cellulose (9.5g). Granulated by method, dried and sieved through a 30-mesh sieve, and blended with low-substituted hydroxypropyl cellulose (9g), magnesium stearate (1.3g) and silicon dioxide (0.6g). Then the obtained granules are pressed ...

Embodiment 2

[0087] Embodiment 2 (sample 5)

[0088] [Table 9] Chip composition

[0089]

[0090] ▲When necessary, use lactose as an adjusting component to change tablet weight.

[0091] [Table 10] Composition of film coating aqueous solution

[0092]

[0093] ▲Purified water accounts for about 90% (w / w) of the film coating aqueous solution.

[0094] The plain tablet (core tablet) containing mosapride citrate was prepared according to the composition ratio shown in the above table [9].

[0095] 15 g of hypromellose was dissolved in 40 g of purified water to obtain a binder solution. The prepared binder solution was added to the wet mixture containing mosapride citrate (5.29g), lactose (46.91g), starch (32.4g) and low-substituted hydroxypropyl cellulose (9.5g) Granulated by method, dried and sieved through a 30-mesh sieve, and blended with low-substituted hydroxypropyl cellulose (9g), magnesium stearate (1.3g) and silicon dioxide (0.6g). Then the obtained granules are pressed int...

Embodiment 3

[0097] Embodiment 3 (sample 6)

[0098] [Table 11] Chip composition

[0099]

[0100] ▲When necessary, use lactose as an adjusting component to change tablet weight.

[0101] [Table 12] Composition of film coating aqueous solution

[0102]

[0103] ▲Purified water accounts for about 90% (w / w) of the film coating aqueous solution.

[0104] The plain tablet (core tablet) containing mosapride citrate was prepared according to the composition ratio shown in the above table [11].

[0105] 45g of purified water was added to the mixture containing mosapride citrate (5.29g), lactose (61.91g), starch (32.4g) and low-substituted hydroxypropyl cellulose (9.5g) for wet granulation, After drying, pass through a 30-mesh sieve to sieve and blend low-substituted hydroxypropylcellulose (9g), magnesium stearate (1.3g) and silicon dioxide (0.6g). Then the obtained granules are pressed into a plain tablet with a hardness of 3-10 kg using a punching film with a diameter of 6.5 mm.

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com