Reduced graphene oxide/porphyrin/platinum nano composite material and preparation and application thereof

A composite material and platinum nanotechnology, applied in the field of photocatalysis, can solve the problems of photocatalytic efficiency that needs to be improved, high cost of synthesis method, unsuitable for popularization and application, and achieve low cost, good photocatalytic performance and simple experimental conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation method of ITO-RGO-TCPP NR-PtNPs nanocomposite:

[0028] Step (1): Preprocessing of ITO

[0029] Put the ITO into a beaker, wash it ultrasonically for 15 minutes with soapy water, double distilled water, acetone, ethanol and double distilled water, and dry it with nitrogen for later use;

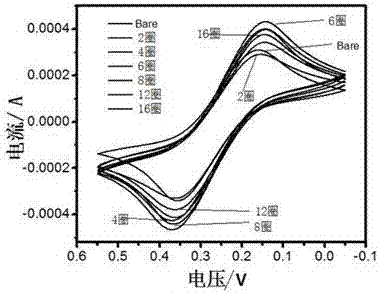

[0030] Step (2): Preparation of RGO thin film

[0031] a. Synthesis of GO: The preparation of GO comes from the improved Hummers method. The specific process is as follows: Accurately weigh 1.5g of flake graphite and 9g of potassium permanganate in a 250mL round bottom flask. Add mixed acid solution (180mL of sulfuric acid and 20mL of phosphoric acid), adjust the temperature of the stirrer, raise the temperature of the mixture in the round bottom flask to 50°C, and keep stirring at this temperature for 12h to obtain a brownish purple liquid; after cooling to room temperature, add 200mL distilled water and 3mL hydrogen peroxide, the liquid is bright yellow at this time; st...

Embodiment 2

[0040] Preparation method of ITO-RGO-TCPP NR-PtNPs nanocomposite:

[0041] The synthesis method of GO in step (1) and step (2) is the same as in Example 1; the concentration of GO aqueous solution in step (2) is 0.9 mg / mL, and the number of deposition circles is 6 circles;

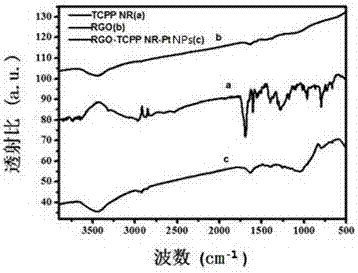

[0042] Step (3): Porphyrin modification of RGO film

[0043] The preparation method of a.TCPP is the same as embodiment 1;

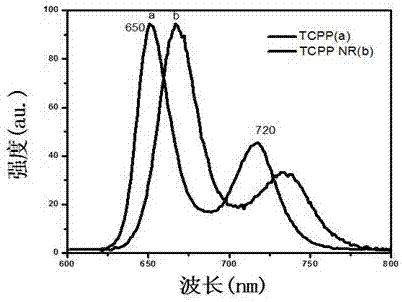

[0044] b. Weigh 4.1mg of TCPP into beaker A, dissolve with 0.5mL 0.2mol / L NaOH solution to obtain liquid A; weigh 42mg of CTAB into beaker B, add 12mL of 0.31% hydrochloric acid solution, Obtain liquid B; quickly pour liquid A into liquid B and stir for 35 minutes to obtain TCPP NR solution, centrifuge at a speed of 5500r / min for 8 minutes, rinse with ultrapure water for 5 times, continue centrifuging to remove excess CTAB, and finally TCPP NR The concentration is 0.51×10 -3 mol / L;

[0045] c. Use a pipette gun to pipette 2.5 μL of the above TCPP NR solution and drop-coat it on t...

Embodiment 3

[0049] Preparation method of ITO-RGO-TCPP NR-PtNPs nanocomposite:

[0050] The synthesis method of GO in step (1) and step (2) is the same as in Example 1; the concentration of GO aqueous solution in step (2) is 0.1mg / mL, and the number of deposition circles is 6 circles;

[0051] Step (3): Porphyrin modification of RGO film

[0052] The preparation method of a.TCPP is the same as embodiment 1;

[0053] b. Weigh 4.25mg of TCPP into beaker A, dissolve it with 0.5mL 0.2mol / L NaOH solution to obtain liquid A; weigh 48mg of CTAB into beaker B, add 12mL of hydrochloric acid solution with a volume fraction of 0.32%, Obtain liquid B; quickly pour liquid A into liquid B and stir for 40 minutes to obtain TCPP NR solution, centrifuge at 6000r / min for 10 minutes, rinse with ultrapure water for 5 times, continue to centrifuge to remove excess CTAB, and finally TCPP NR The concentration is 0.53×10 -3 mol / L;

[0054] c. Use a pipette gun to pipette 5 μL of the above TCPP NR solution and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com