Preparation method of activated carbon fiber membrane loaded TiO2/ZnO photocatalyst

A technology of activated carbon fiber and photocatalyst, which is applied in the field of porous nanomaterials, can solve the problems of increased preparation cost, catalyst shedding, and low loading capacity, and achieve the effects of simple preparation method, large specific surface area, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

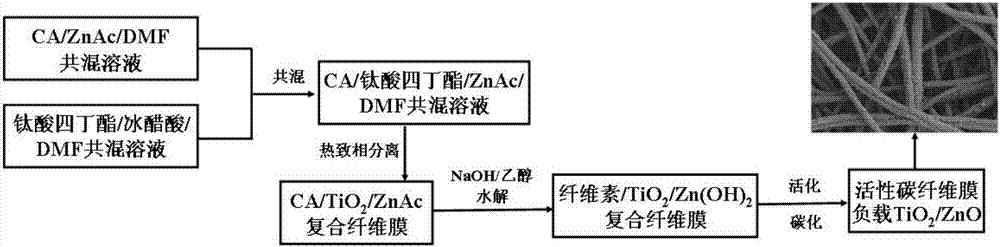

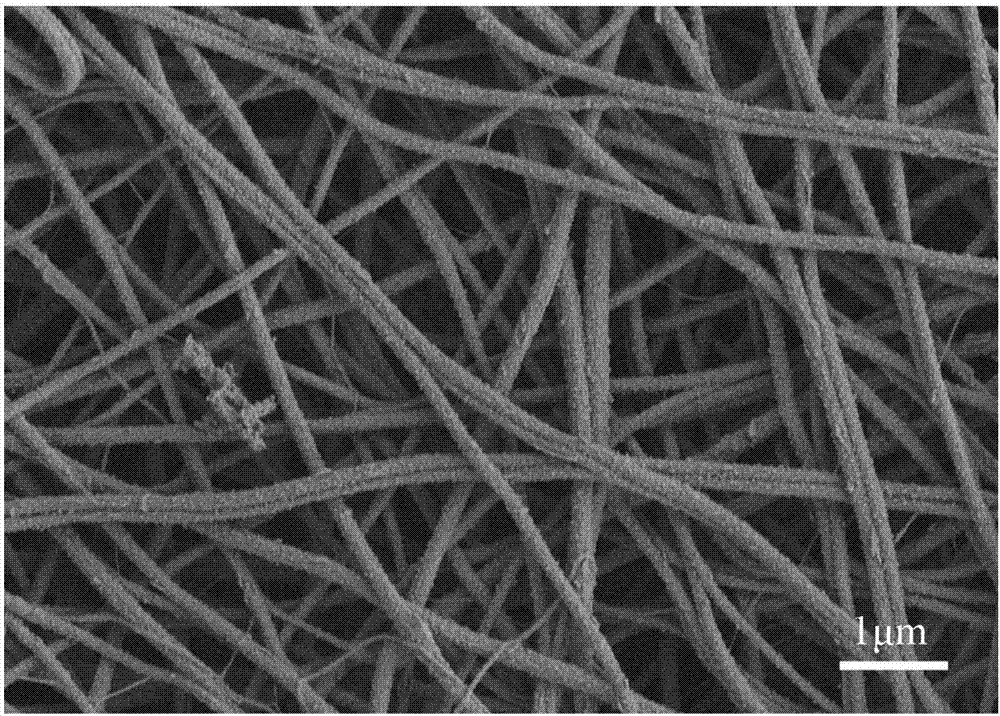

[0038] A kind of active carbon fiber loaded TiO that this embodiment relates to 2 / ZnO photocatalyst preparation method, such as figure 1shown, including the following steps:

[0039] 1. Add 5g of cellulose acetate into 55g of dimethylformamide solvent, stir magnetically for 3 hours to dissolve completely, add 1.5g of zinc acetate to the cellulose acetate / dimethylformamide solution, stir magnetically for 3 hours at room temperature to make it completely dissolve. Add 1.2 g of tetrabutyl titanate into a mixed solvent of 30 g of dimethylformamide and 2 g of glacial acetic acid, and dissolve under magnetic stirring at room temperature. The two solutions prepared above were mixed together, and magnetically stirred for 3 hours at room temperature to obtain a quenching solution.

[0040] 2. Pour the above-mentioned quenching solution into a petri dish with a diameter of 7.5 cm, and put it into a preset -20°C low-temperature refrigerator for quenching for 60 minutes. After quench...

Embodiment 2

[0047] A kind of active carbon fiber loaded TiO that this embodiment relates to 2 The preparation method of / ZnO photocatalyst comprises the steps:

[0048] 1. Add 7g of cellulose acetate into 60g of dimethylformamide solvent, stir magnetically for 3 hours to make it completely dissolved, add 0.8g of zinc acetate to the cellulose acetate / dimethylformamide solution, stir magnetically for 3 hours at room temperature to make it completely dissolve. 1 g of tetrabutyl titanate was added into a mixed solvent of 34 g of dimethylformamide and 2 g of glacial acetic acid, and dissolved by magnetic stirring at room temperature. The two solutions prepared above were mixed together, and magnetically stirred for 3 hours at room temperature to obtain a quenching solution.

[0049] 2. Pour the above quenching solution into a petri dish with a diameter of 7.5 cm, and put it into a preset -30°C refrigerator for quenching for 60 minutes. After quenching, quickly take out the Petri dish, add 30...

Embodiment 3

[0056] A kind of active carbon fiber loaded TiO that this embodiment relates to 2 The preparation method of / ZnO photocatalyst comprises the steps:

[0057] 1. Add 7g of cellulose acetate to 60g of dimethylformamide solvent, stir magnetically for 3 hours to dissolve completely, add 1g of zinc acetate to the cellulose acetate / dimethylformamide solution, stir magnetically for 3 hours at room temperature to dissolve completely . 1 g of tetrabutyl titanate was added into a mixed solvent of 34 g of dimethylformamide and 2 g of glacial acetic acid, and dissolved by magnetic stirring at room temperature. The two solutions prepared above were mixed together, and magnetically stirred for 3 hours at room temperature to obtain a quenching solution.

[0058] 2. Pour the above quenching solution into a petri dish with a diameter of 7.5 cm, and put it into a preset -30°C refrigerator for quenching for 60 minutes. After quenching, quickly take out the Petri dish, add 300mL ethanol to the P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com