Medical blue laser printing film and preparation method

A blue laser and laser printing technology, applied in the field of medical supplies, can solve the problems of damaged printer parts, poor adhesion fastness of toner, insufficient load capacity, etc., and achieve the effect of simple manufacturing method, elimination of electrostatic adsorption, and no solvent residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

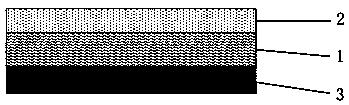

[0030] The preparation method of described medical blue laser printing film, comprises the following steps:

[0031] Step ①: preparation of laser printing coating 2 coating; laser printing coating 2, consisting of the following parts by weight: styrene-acrylic emulsion: 100 parts; ion-exchange type silica sol: 20 parts; large particle size silica sol: 12 parts; water : 63 parts; Sodium polystyrene sulfonate: 0.5 part; The preparation method of laser printing coating 2 comprises the following steps:

[0032] Step a: using styrene-acrylic emulsion with a pH value of 8-9 as the base material, slowly mixing silica sol, stirring at 500 rpm for 1 hour, and mixing the materials evenly;

[0033] Step b: add the water dilution of sodium polystyrene sulfonate, stir at low speed for 10 minutes, filter through a 300-mesh filter, and let stand for defoaming for later use.

[0034] Step ②: Laser printing coating 2 Coating: slope flow extrusion coating, heating and drying with steam, the pr...

Embodiment 2

[0043] Blue antistatic layer 3 component embodiment 2 (preferred embodiment)

[0044] It consists of the following parts by weight: acrylonitrile modified water-based styrene-butadiene latex: 100 parts; blue pigment paste: 0.15 parts; polyaniline antistatic agent: 5 parts; leveling agent: 0.1 part; defoamer: 0.1 part ; Water: 50 parts.

Embodiment 3

[0046] It consists of the following parts by weight: acrylonitrile modified water-based styrene-butadiene latex: 110 parts; blue pigment paste: 0.2 parts; polyaniline antistatic agent: 6 parts; leveling agent: 0.15 parts; defoamer: 0.15 parts ; Water: 55 parts.

[0047] Concrete implementation of the present invention:

[0048] 1. For the front laser printing coating 2:

[0049] Laser printing coating 2 has many advantages such as excellent high-temperature adhesion fastness, weather resistance, high printing color density, antistatic performance and anti-blocking property;

[0050] 1. Select some polymerized monomers with short methyl side groups, ester groups-COOR strong polar side groups and benzene rings (including: methyl methacrylate, methacrylic acid, butyl methacrylate, butyl acrylate , 2-ethylhexyl acrylate, styrene, etc.), using emulsion polymerization technology, a styrene-acrylic emulsion with low flexibility and low friction coefficient was synthesized; the phys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com