Preparation method of edible nanofiber preservative film

A nanofiber and cling film technology, which is used in rot-proof containers, flexible coverings, textiles and paper making, etc., can solve the problems of uneven surface distribution of fruits and vegetables, inconsistent fresh-keeping effects of fruits and vegetables, and different film thicknesses, and achieve weight loss rate. Reduced, good preservation effect, uniform diameter distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

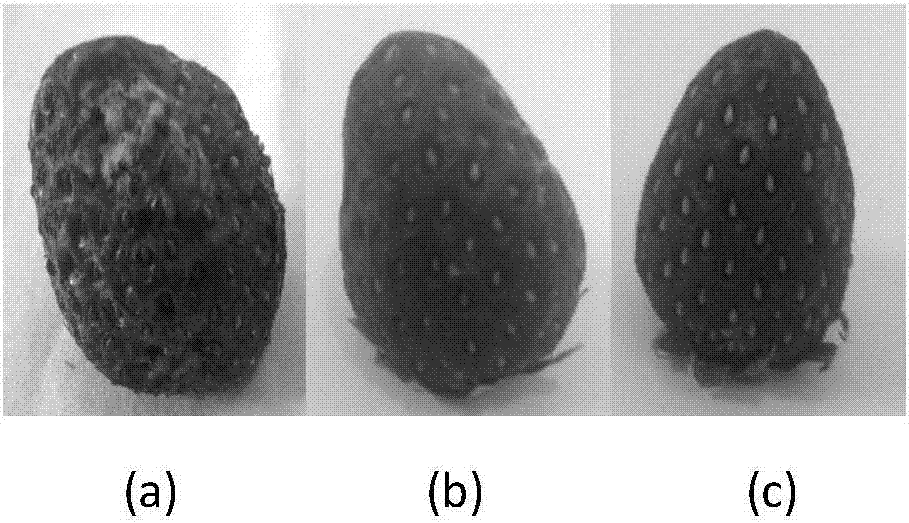

Examples

Embodiment 1

[0034] (1) Prepare 95% ethanol solution at room temperature and set aside.

[0035] (2) Dissolving the pullulan in the ethanol solution in step (1) so that the mass concentration of the pullulan is 18%, and fully stirring until completely dissolved.

[0036] (3) Add carboxymethyl cellulose to make its mass concentration 1.5%, stir well until it dissolves completely, and obtain the basic spinning solution.

[0037] (4) Then in the basic spinning solution of step (3), add tea polyphenols and sodium citrate to make the mass concentration of the two be 1% and 0.5% respectively, stir evenly with a magnetic stirrer, and leave standstill until the bubbles are completely Disappeared, the spinning solution was obtained.

[0038](5) Draw the spinning solution obtained in step (4) with a syringe, place it on an electrospinning machine, and perform electrospinning. Among them, electrostatic voltage: 18kv; acceptance distance: 13-16cm; needle type: inner diameter 0.6mm, outer diameter 0....

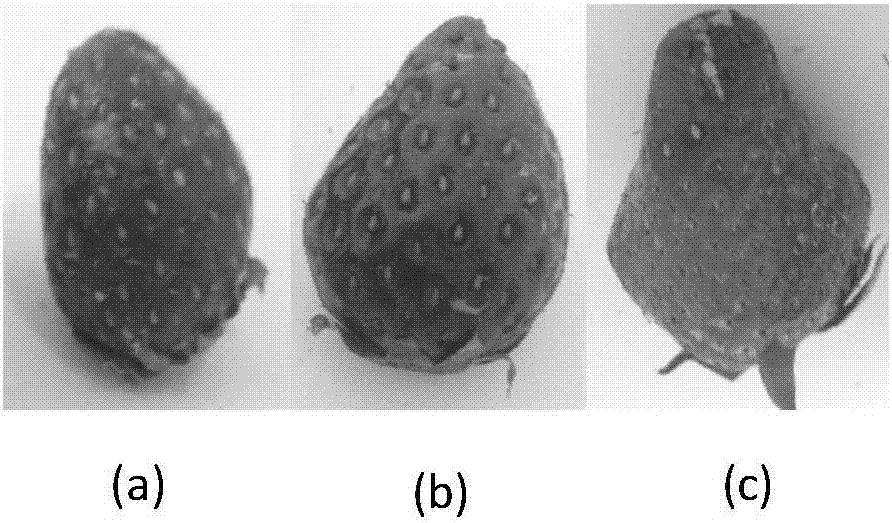

Embodiment 2

[0057] (1) Prepare 95% ethanol solution at room temperature and set aside.

[0058] (2) Dissolving the pullulan in the ethanol solution in step (1) so that the mass concentration of the pullulan is 18%, fully stirring until completely dissolved.

[0059] (3) Add carboxymethyl cellulose to make its mass concentration 1%, stir well until it dissolves completely

[0060] (4) Then in the step (3) spinning solution, add tea polyphenols and sodium citrate to make the mass concentration of the two be 1% and 0.5% respectively, stir evenly with a magnetic stirrer, and leave standstill until the bubbles disappear completely.

[0061] (5) Draw the spinning solution with a syringe, place it on an electrostatic spinning machine, and perform electrostatic spinning. Among them, electrostatic voltage: 18kv; acceptance distance: 13-16cm; needle type: inner diameter 0.6mm, outer diameter 0.9mm; room temperature: 25°C; air humidity: 65%.

[0062] (6) Cut the obtained nanofiber film with a thic...

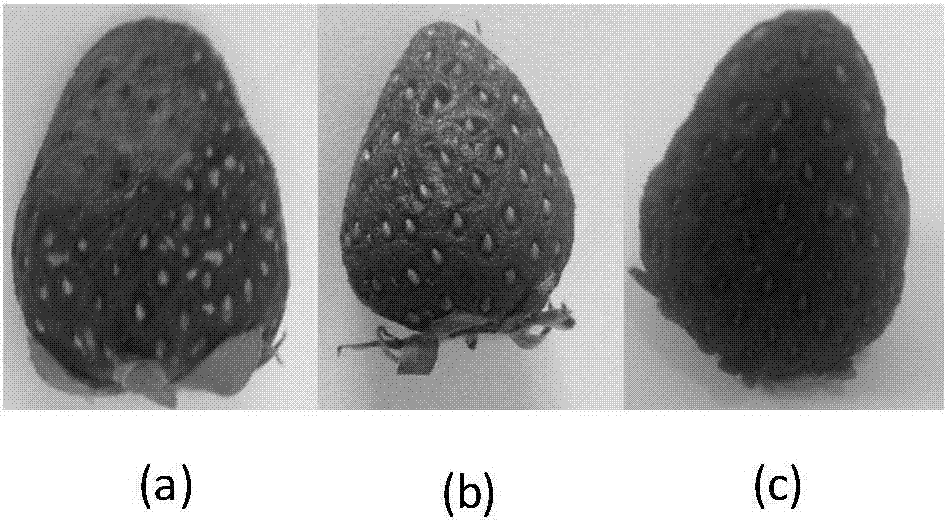

Embodiment 3

[0077] (1) Prepare 95% ethanol solution at room temperature and set aside.

[0078] (2) Dissolving the pullulan in the ethanol solution in step (1) so that the mass concentration of the pullulan is 18%, fully stirring until completely dissolved.

[0079] (3) Add carboxymethyl cellulose to make its mass concentration 2%, stir well until it dissolves completely

[0080] (4) Then in the step (3) spinning solution, add tea polyphenols and sodium citrate to make the mass concentration of the two be 1% and 0.5% respectively, stir evenly with a magnetic stirrer, and leave standstill until the bubbles disappear completely.

[0081] (5) Draw the spinning solution with a syringe, place it on an electrostatic spinning machine, and perform electrostatic spinning. Among them, electrostatic voltage: 18kv; acceptance distance: 13-16cm; needle type: inner diameter 0.6mm, outer diameter 0.9mm; room temperature: 25°C; air humidity: 65%.

[0082] (6) Cut the obtained nanofiber film with a thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com