Production method of preparing corn peptide powder by means of bionic enzymatic hydrolysis

A biomimetic enzymatic hydrolysis and peptide powder technology, which is applied to the preparation methods of peptides, chemical instruments and methods, peptides, etc., can solve the problems of waste of resources, poor water solubility, etc., and achieve the effects of low cost, simple preparation process, and no toxic and side effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 This embodiment comprises the following steps:

[0026] (1) Add 20 liters of purified water to the bionic enzymolysis tank, start the stirring paddle, set the rotating speed at 60 rpm, take 2 kg of corn gluten powder (corn protein isolate, protein content is more than 90%, and water content is less than 10%), slowly Add, continue to stir and swell for 30 minutes after the addition is complete, heat the interlayer to 80-85°C for 15 minutes to sterilize, pass cooling water to the interlayer to cool down to about 55°C in the tank, start the interlayer water and heater circulation, and the heater heats up Keep warm at 55°C;

[0027] (2) Start the pH detection terminal, add dilute hydrochloric acid to the bionic enzymolysis tank to adjust the pH value to 2.0 with a peristaltic pump, add 1% pepsin (enzyme activity: 3000U / g) of zein content, keep warm for 1 hour, and Monitor the pH value and add dilute hydrochloric acid to keep the pH value within the range of 1....

Embodiment 2

[0031] Embodiment 2 This embodiment comprises the following steps:

[0032] (1) Add 40 liters of purified water to the bionic enzymolysis tank, start the stirring paddle, set the speed at 30 rpm, take 2 kg of corn gluten powder, add it slowly, continue to stir and swell for 30 minutes after the addition, and heat the interlayer with steam until Sterilize at 80-85°C for 15 minutes, cool the interlayer with cooling water to about 50°C inside the tank, start the interlayer water and heater cycle, and heat the heater to 50°C to keep warm;

[0033](2) Start the pH detection terminal, add dilute hydrochloric acid to the bionic enzymolysis tank with a peristaltic pump to adjust the pH value to 1.8, add 3% pepsin in the amount of zein, keep the enzymolysis for 3 hours, monitor the pH value at any time, supplement dilute hydrochloric acid to maintain The pH value is in the range of 1.8-2.2;

[0034] (3) Add 40% sodium hydroxide to the bionic enzymolysis tank to adjust the pH value to ...

Embodiment 3

[0037] Example 3 corn peptide powder:

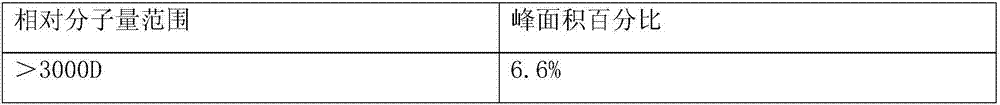

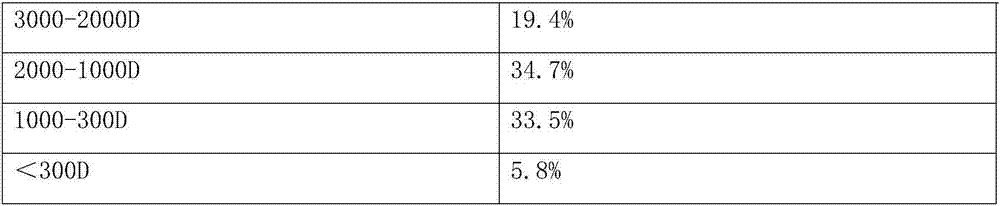

[0038] Get the corn peptide powder obtained by the industrial production method described in Example 1, after testing: its total protein content is 92%, the trichloroacetic acid soluble small molecule peptide content is 86%, the free amino acid content is 3.7%, and the moisture content is 5.3%, and the relative molecular weight distribution is:

[0039]

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com