Preparation method of green-fluorescence-labeled terbium/strontium codoped hydroxyapatite nano particles with high luminous intensity

A technology of hydroxyapatite and luminous intensity, which is applied in nanotechnology, nanotechnology, luminescent materials, etc. for materials and surface science. It can solve the problems of fluorescence quenching and high rare earth content, and achieve reduced usage and high economy. benefit, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A method for preparing green fluorescent-labeled terbium / strontium co-doped hydroxyapatite nanoparticles with high luminous intensity, comprising the following steps:

[0029] (1) First, weigh a certain amount of Tb 4 o 7 Solid powder, add excess concentrated nitric acid solution to it, heat in a water bath at 85°C, add a small amount of deionized water after the nitric acid is fully volatilized, continue to evaporate until crystallization forms Tb(NO 3 ) 3 Crystals, prepared with deionized water and constant volume to obtain terbium nitrate solution, ready for use.

[0030] (2) Then, take a certain amount of calcium nitrate, strontium nitrate, diammonium hydrogen phosphate and sodium hydroxide and dissolve it with deionized water to form a solution. The terbium nitrate solution prepared in (1) and calcium nitrate solution, nitric acid The strontium solution is mixed evenly, and the diammonium hydrogen phosphate solution is slowly added dropwise to the above mixed so...

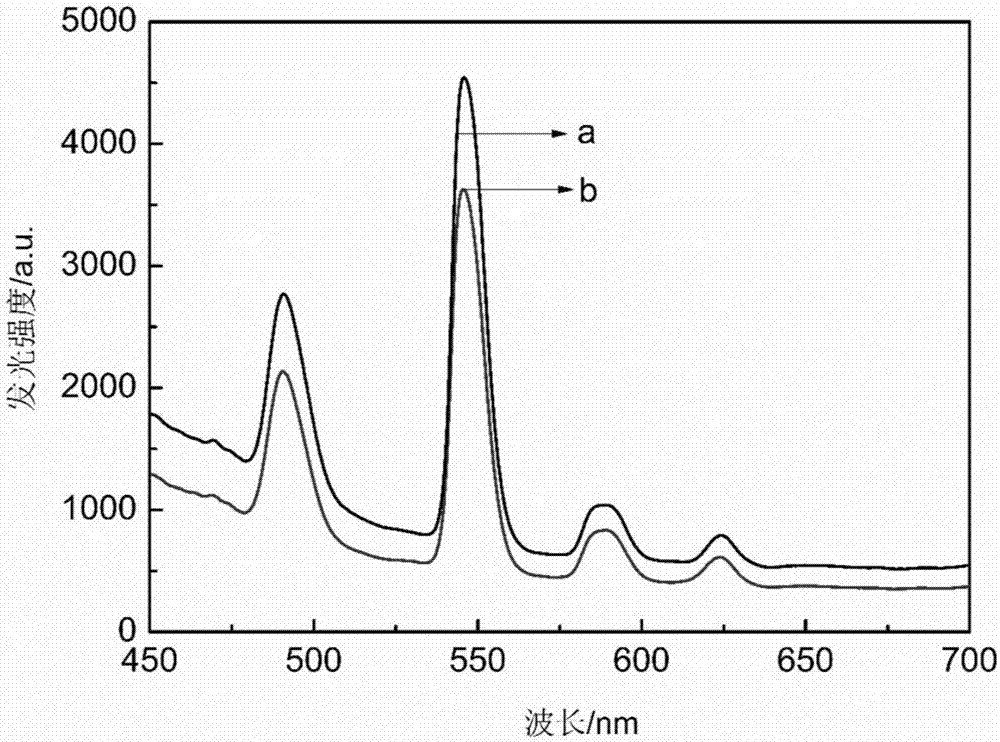

Embodiment 1

[0034] (1) First, weigh 0.56g of Tb 4 o 7 Solid powder, add excess concentrated nitric acid solution to it, heat in a water bath at 85°C, add a small amount of deionized water after the nitric acid is fully volatilized, continue to evaporate until crystallization forms Tb(NO 3 ) 3 Crystals, then prepared with deionized water and fixed to 0.5mol / L Tb 3+ Solution 6mL, ready to use.

[0035] (2) Prepare 90 mL of 0.5 mol / L calcium nitrate solution, 10 mL of 0.5 mol / L strontium nitrate solution, and 50 mL of 0.6 mol / L ammonium hydrogen phosphate solution with distilled water, and mix the above nitrate solutions (calcium nitrate solution, strontium nitrate solution and Terbium nitrate solution) mixed and stirred evenly. Then, the diammonium hydrogen phosphate solution is slowly added dropwise to the above mixed solution, placed on a magnetic stirrer and continuously stirred, and after being fully mixed, the pH value of the reaction system is adjusted to 14 with 2mol / L NaOH solut...

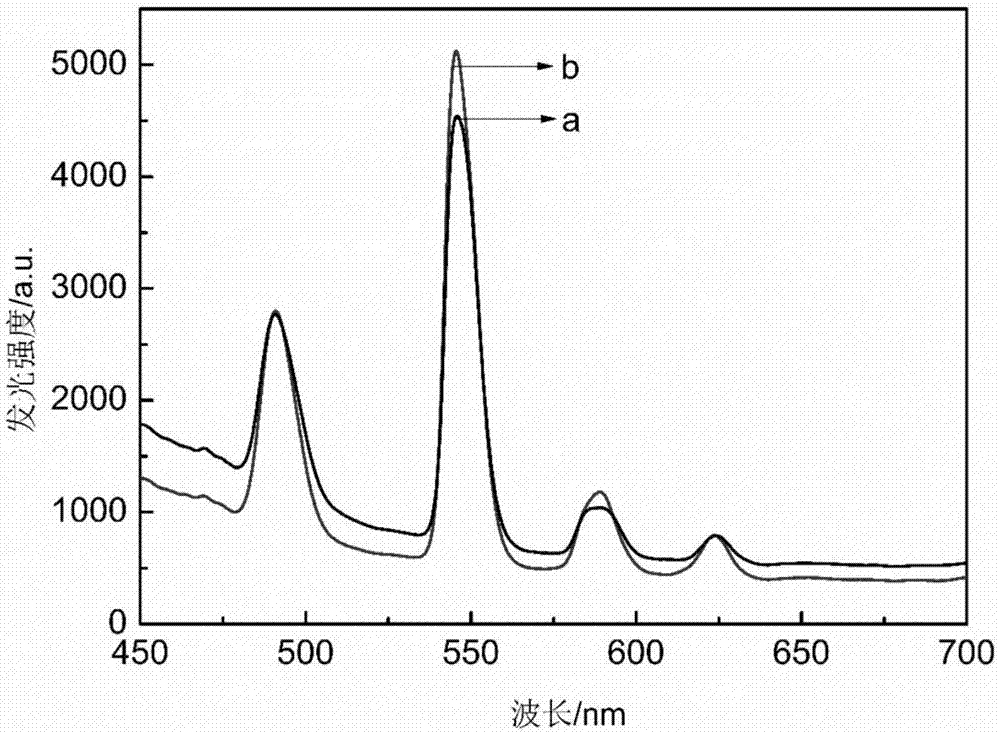

Embodiment 2

[0038] (1) First, weigh 0.56g of Tb 4 o 7 Solid powder, add excess concentrated nitric acid solution to it, heat in a water bath at 85°C, add a small amount of deionized water after the nitric acid is fully volatilized, continue to evaporate until crystallization forms Tb(NO 3 ) 3 Crystals, then prepared with deionized water and fixed to 0.5mol / L Tb 3+ Solution 6mL, ready to use.

[0039] (2) Prepare 70 mL of 0.5 mol / L calcium nitrate solution, 30 mL of 0.5 mol / L strontium nitrate solution, and 50 mL of 0.6 mol / L diammonium hydrogen phosphate solution with distilled water. Terbium nitrate solution) mixed and stirred evenly. Then, the diammonium hydrogen phosphate solution is slowly added dropwise to the above mixed solution, placed on a magnetic stirrer and continuously stirred, and after being fully mixed, the pH value of the reaction system is adjusted to 14 with 2mol / L NaOH solution. Stirring was continued for 4h after stabilization.

[0040] (3) After the stirring is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com