Preparation method and application of photocatalyst, copper calcium titanate containing high-density oxygen vacancy

A technology of calcium copper titanate and photocatalyst, applied in metal/metal oxide/metal hydroxide catalyst, chemical instrument and method, chemical element of heterogeneous catalyst, etc., can solve the problem of inability to use visible light, wide band gap, etc. problem, to achieve the effect of high crystallinity, uniform size distribution and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

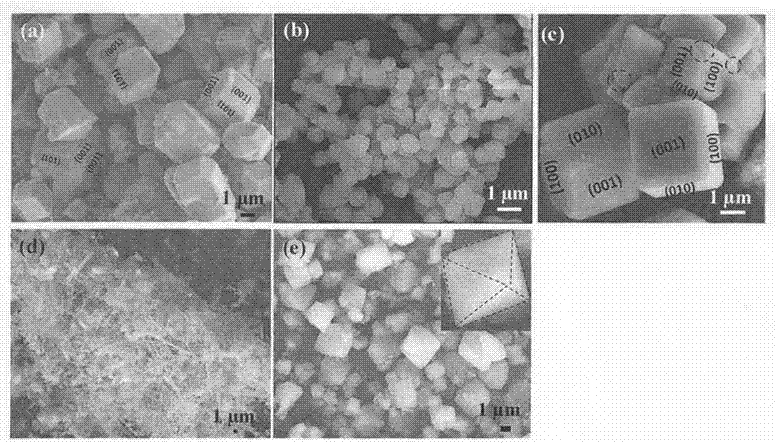

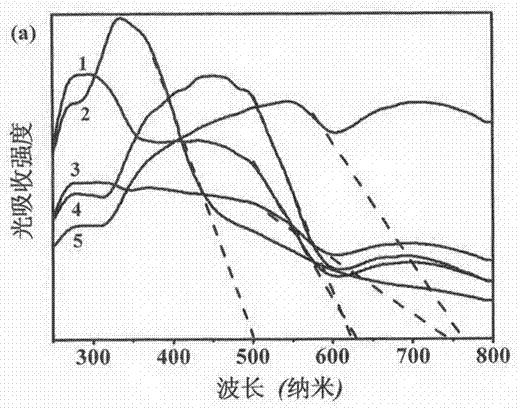

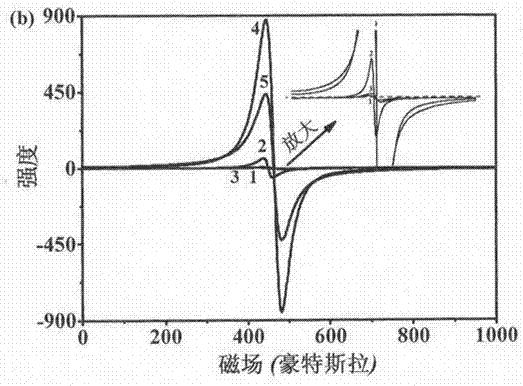

Embodiment 1

[0021] a. Accurately weigh 0.0049mol of calcium oxide 0.28g, 0.0146mol of copper oxide 1.1645g, and 0.019mol of titanium dioxide 1.56g in a molar ratio, and grind at a constant speed for 30 minutes to obtain a uniform and fine powder mixture;

[0022] b. Add 4.7028 g of 0.1 mol molten salt sodium fluoride to the mixture obtained in step a, and continue grinding for 120 minutes to obtain a uniform mixture of fine particles;

[0023] c. Pour the mixed powder obtained in step b into a crucible, place it in a high-temperature tube furnace, raise the temperature to 800°C in 400 minutes at a heating rate of 2°C / min, and react for 6 hours to obtain a solid powder;

[0024] d. Remove the solid powder obtained in step c from the crucible, grind it evenly for 40 minutes, pour it into a beaker filled with 800mL water and stir for 5 hours, let it stand for 30 minutes, so that all the particles sink, and then slowly pour out the supernatant , continue to stir with 100mL of absolute ethanol...

Embodiment 2

[0026] a. Accurately weigh 0.0049mol of calcium oxide 0.28g, 0.0146mol of copper oxide 1.1645g, and 0.019mol of titanium dioxide 1.56g in a molar ratio, and grind at a constant speed for 30 minutes to obtain a uniform and fine powder mixture;

[0027] b. Add 5.844 g of 0.1mol molten salt sodium chloride to the mixture obtained in step a, and continue grinding for 120 minutes to obtain a uniform mixture of fine particles;

[0028]c. Pour the mixed powder obtained in step b into a crucible, place it in a high-temperature tube furnace, raise the temperature to 800° C. in 400 minutes at a heating rate of 2° C. / min, and react for 6 hours to obtain a solid powder;

[0029] d. Remove the solid powder obtained in step c from the crucible, grind it evenly for 40 minutes, pour it into a beaker filled with 800mL water and stir for 5 hours, let it stand for 30 minutes, so that all the particles sink, and then slowly pour out the supernatant , continue to stir with 100mL of absolute ethano...

Embodiment 3

[0031] a. Accurately weigh 0.0049mol of calcium oxide 0.28g, 0.0146mol of copper oxide 1.1645g, and 0.019mol of titanium dioxide 1.56g in a molar ratio, and grind at a constant speed for 30 minutes to obtain a uniform and fine powder mixture;

[0032] b. Add 10.289 g of 0.1 mol molten salt sodium bromide to the mixture obtained in step a, and continue grinding for 120 minutes to obtain a uniform mixture of fine particles;

[0033] c. Pour the mixed powder obtained in step b into a crucible, place it in a high-temperature tube furnace, raise the temperature to 800° C. in 400 minutes at a heating rate of 2° C. / min, and react for 6 hours to obtain a solid powder;

[0034] d. Remove the solid powder obtained in step c from the crucible, grind it evenly for 40 minutes, pour it into a beaker filled with 800mL water and stir for 5 hours, let it stand for 30 minutes, so that all the particles sink, and then slowly pour out the supernatant , continue to stir with 100mL of absolute etha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com