Even-structure and high-permeability microporous membrane used for filtering, and preparation method thereof

A technology of air permeability and microporous membrane, applied in the field of microporous membrane for high permeability filtration and its preparation, can solve the problems of poor deformation resistance and heat resistance, low efficiency of air filtration membrane, low mechanical strength, etc. The effect of production cost, cost reduction, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

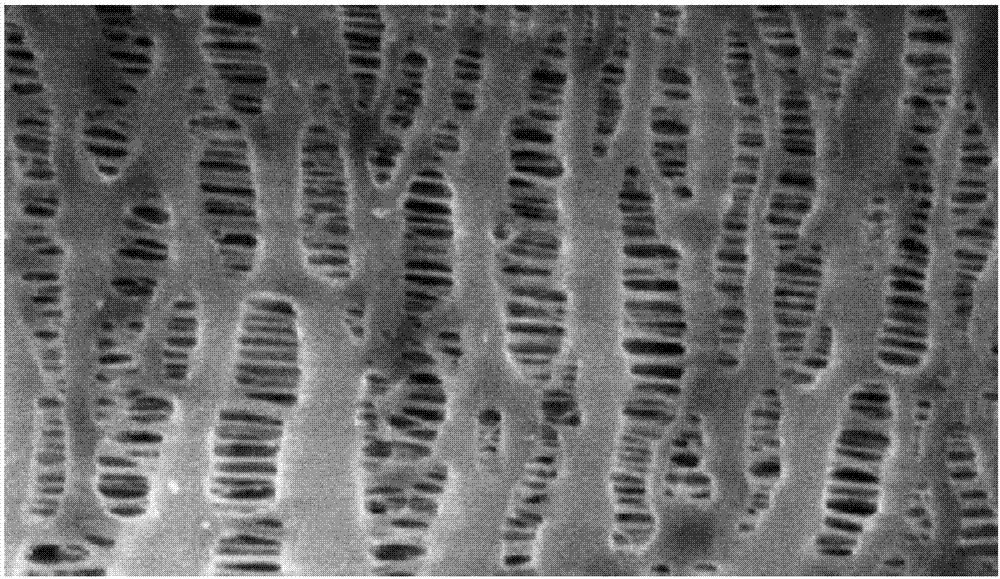

Image

Examples

Embodiment 1

[0034] A microporous membrane with uniform structure and high air permeability for filtration, which is composed of the following raw materials in parts by weight:

[0035] Polyethylene 110, acrylonitrile 30, dicumyl peroxide 0.2, plasticizer 4, antimony trioxide 2, zinc borate 1, triethanolamine 2, dibasic lead phosphite 2, octylisothiazolinone 2 , calcium propionate 3, triglycidyl isocyanurate 2, diacetone alcohol 6, oleic acid diethanolamide 1, sodium myristate soap 1, glycolic acid 2.

[0036] A method for preparing a microporous membrane with uniform structure and high air permeability filtration, comprising the following steps:

[0037] (1) Take octylisothiazolinone, add it to deionized water 20 times its weight, stir evenly, add calcium propionate, raise the temperature to 50°C, keep stirring for 9 minutes, add diacetone alcohol, continue to keep warm and stir 20 minutes to get antibacterial lotion;

[0038] (2) Take sodium myristate soap, add it to 9 times its weight...

Embodiment 2

[0049] A microporous membrane with uniform structure and high air permeability for filtration, which is composed of the following raw materials in parts by weight:

[0050] Polyethylene 100, acrylonitrile 27, dicumyl peroxide 0.1, plasticizer 2, antimony trioxide 1, zinc borate 0.8, stannous sulfide 1, isooctyl dimercaptoacetate 0.8, octylisothiazolinone 1. Calcium propionate 1, triglycidyl isocyanurate 0.7, diacetone alcohol 4, oleic acid diethanolamide 0.7, sodium myristate soap 0.5, glycolic acid 1.

[0051] A method for preparing a microporous membrane with uniform structure and high air permeability filtration, comprising the following steps:

[0052] (1) Take octylisothiazolinone, add it to deionized water 17 times its weight, stir evenly, add calcium propionate, raise the temperature to 40°C, keep stirring for 4 minutes, add diacetone alcohol, continue to keep warm and stir 10 minutes, get antibacterial lotion;

[0053] (2) Take sodium myristate soap, add it to 6 time...

Embodiment 3

[0064] A microporous membrane with uniform structure and high air permeability for filtration, which is composed of the following raw materials in parts by weight:

[0065] Polyethylene 110, acrylonitrile 27, dicumyl peroxide 0.1, plasticizer 2, antimony trioxide 1-zinc borate 0.8, antioxidant 1, heat stabilizer 0.9, octylisothiazolinone 1, propionic acid Calcium 2, triglycidyl isocyanurate 0.9, diacetone alcohol 4, oleic acid diethanolamide 0.8, sodium myristate soap 0.7, glycolic acid 1.

[0066] Described antioxidant is zinc ricinoleate.

[0067] The heat stabilizer is tribasic lead carbonate.

[0068] A method for preparing a microporous membrane with uniform structure and high air permeability filtration, comprising the following steps:

[0069] (1) Take octylisothiazolinone, add it to deionized water 17 times its weight, stir evenly, add calcium propionate, raise the temperature to 48°C, keep stirring for 7 minutes, add diacetone alcohol, continue to keep warm and stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com