Chromate-free passivation liquid for zinc alloy

A chromium-free passivation and zinc alloy technology, which is applied in the coating process of metal materials, etc., can solve problems such as health hazards of plated parts, negative impacts on human health, and serious environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

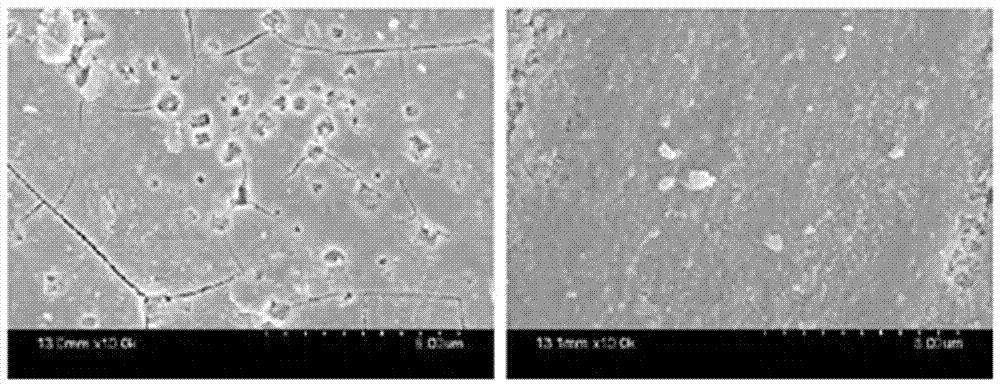

Image

Examples

Embodiment 1

[0017] A chromium-free passivation solution for zinc alloys, which consists of the following components in parts by weight: 20 parts of sodium molybdate, 15 parts of titanium sulfate, 5 parts of potassium fatty acid, 10 parts of ester alcohol, 35 parts of hydrogen peroxide, hydroxyethyl 2 parts of cellulose, 40 parts of deionized water.

[0018] When the above-mentioned zinc alloy is passivated with a chromium-free passivation solution, the zinc alloy workpiece is degreased and dewaxed, then washed with hot water, then soaked in a pH=3 solution at 40°C for 15 seconds, and washed with water for 70 seconds. ℃ drying to complete the passivation treatment.

[0019] Zinc alloy passivation performance comparison test table

[0020] workpiece Passivation time s Acid salt spray test h Workpiece Appearance Zinc alloy 0 4 white corrosion Zinc alloy 15 16 no change

Embodiment 2

[0022] A chromium-free passivation solution for zinc alloys, which consists of the following components in parts by weight: 20 parts of sodium molybdate, 25 parts of titanium sulfate, 8 parts of potassium stearate, 7 parts of ester alcohol, 30 parts of hydrogen peroxide, and 5 parts of triol, 45 parts of deionized water.

[0023] When the above-mentioned zinc alloy is passivated with a chromium-free passivation solution, the zinc alloy workpiece is washed with hot water after degreasing and wax removal, and then soaked in a pH=4 solution at 60°C for 10 seconds after washing with water. ℃ drying to complete the passivation treatment.

[0024] Zinc alloy passivation performance comparison test table

[0025] workpiece Passivation time s Acid salt spray test h Workpiece Appearance Zinc alloy 0 4 white corrosion Zinc alloy 15 16 no change

Embodiment 3

[0027] A chromium-free passivation solution for zinc alloys, which consists of the following components in parts by weight: 20 parts of sodium molybdate, 25 parts of titanium sulfate, 8 parts of potassium myristate, 5 parts of n-octanol, 30 parts of hydrogen peroxide, glycerin 3 parts of alcohol, 50 parts of deionized water.

[0028] When the above-mentioned zinc alloy is passivated with a chromium-free passivation solution, the zinc alloy workpiece is washed with hot water after degreasing and wax removal, and then soaked in a pH=4 solution at 60°C for 10 seconds after washing with water. ℃ drying to complete the passivation treatment.

[0029] Zinc alloy passivation performance comparison test table

[0030] workpiece Passivation time s Acid salt spray test h Workpiece Appearance Zinc alloy 0 4 white corrosion Zinc alloy 15 16 no change

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com