A kind of proton exchange membrane applied to methanol fuel cell and preparation method thereof

A methanol fuel cell, proton exchange membrane technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of high cost, high methanol, permeation, etc., and achieve the effects of avoiding damage, simple preparation method and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

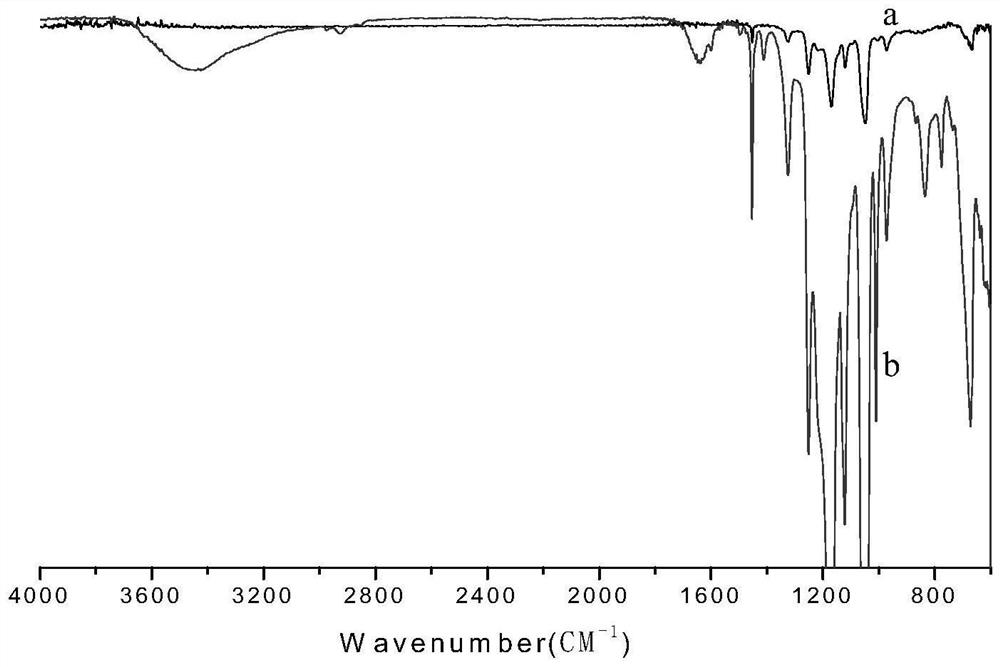

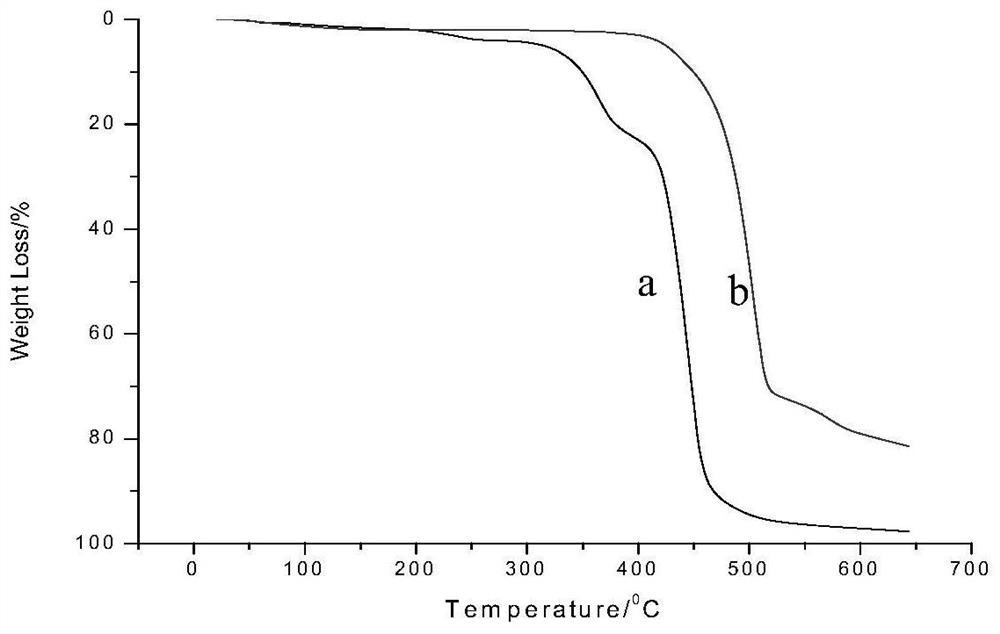

[0027] (1) Select the base film polyethylene-polytetrafluoroethylene (ETFE), cut it into a size of 7cm×7cm, clean it with acetone, and then dry it in a vacuum oven for 24 hours, take it out and weigh it.

[0028] (2) The film was irradiated with a dose of 100 KGy.

[0029] (3) Carry out grafting and crosslinking to the radiation film, the grafting solution is 40ml styrene, 3ml isoprene, 57ml toluene. React at 60°C for 4h.

[0030] (4) Dry the grafted cross-linked film, measure the grafting rate, and the formula for calculating the grafting rate is (W-W 0 ) / W 0 ; where W represents the weight after grafting, W 0 initial weight.

[0031] (5) Sulfonate the membrane by using 2% chlorosulfonic acid solution at room temperature for 4 hours.

[0032] (6) Hydrolysis transformation, put the membrane into a beaker, add 1M sodium hydroxide solution for hydrolysis at 80°C for 12H, and then transform with 0.5M sulfuric acid solution at 80°C for 4h.

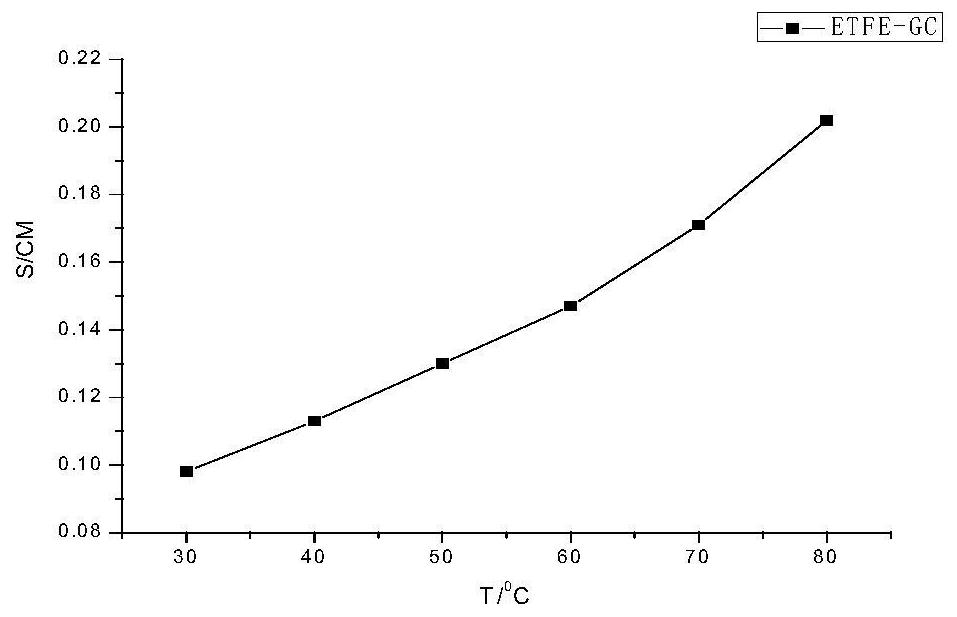

[0033] After testing, the graftin...

Embodiment 2

[0037] Adopt the method of embodiment 1, the difference lies in step (2), we adopt the dose of 20KGy to irradiate, other things remain unchanged.

[0038] After testing, the grafting ratio of the proton exchange membrane prepared in Example 2 was 19.97%, the ion conductivity at 30° C. was 0.053 S / cm, and the water content was 18.56%.

Embodiment 3

[0040] Adopt the method of embodiment 1, the difference lies in step (2), we adopt the dose of 300KGy to irradiate, other things remain unchanged.

[0041] After testing, the proton exchange membrane prepared in Example 3 has a grafting rate of 27.74%, an ion conductivity of 0.091 S / cm at 30° C., and a water content of 23.65%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com