A kind of multi-defect multi-doped titanium dioxide nanoparticles with high visible light catalytic activity and preparation method

A technology of titanium dioxide and catalytic activity, which is applied in the field of preparation of titanium dioxide nano-photocatalysts, can solve the problems of low quantum efficiency of titanium dioxide, and achieve the effect of improving photocatalytic activity, improving catalytic performance, and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

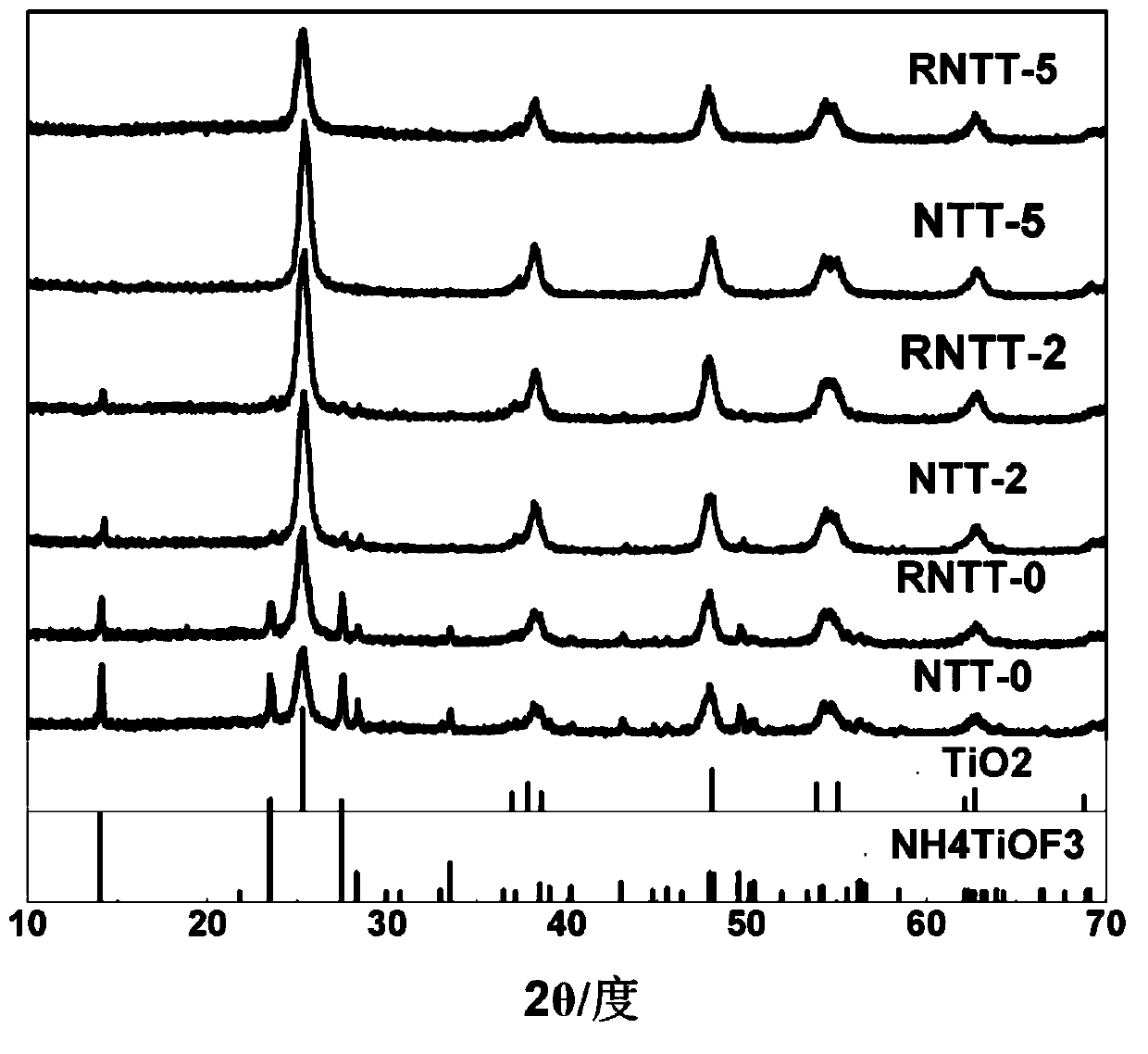

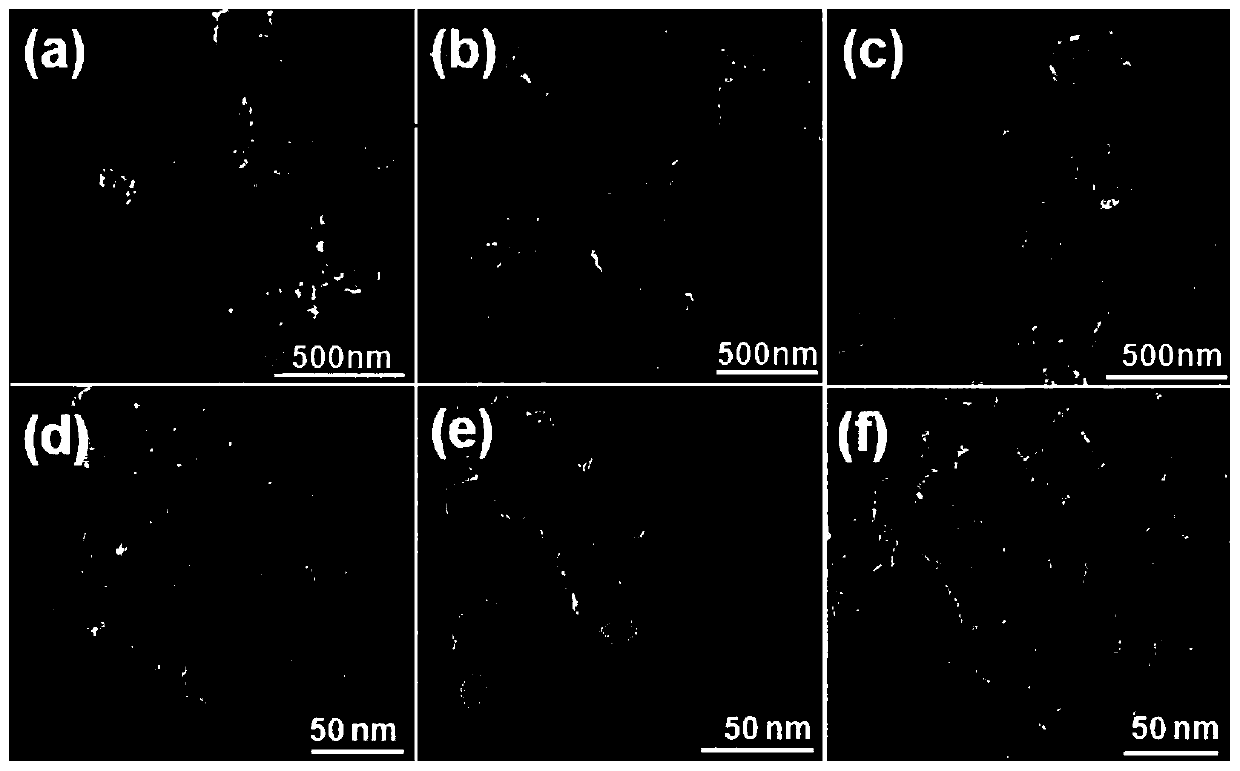

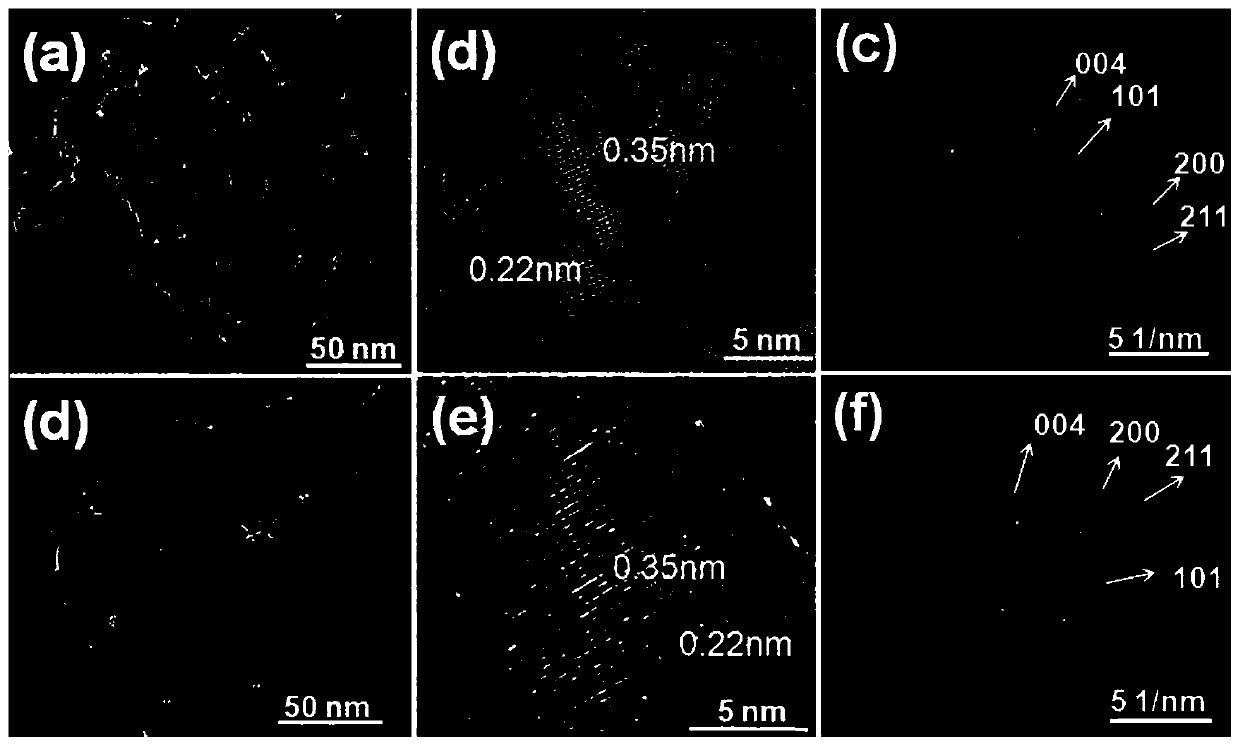

[0031] Take 0.5583g of ammonium hexafluorotitanate and dissolve it in 2ml of deionized water and 3ml of acetic acid, add it dropwise to the mixture of 4ml of tetrabutyl titanate and 20ml of isopropanol during vigorous stirring, and continue stirring in ice bath for 5h , transferred to a 50ml reactor, and heated at 180°C for 5h. Cool to room temperature, wash with ethanol and deionized water, and dry under vacuum at 60 °C to obtain NH 4 TiOF 3 with TiO 2 The mixture, denoted as NTT. Disperse 0.5g NTT into 50ml 0.5mol / l boric acid solution, stir in water bath at 40°C for different times to obtain NH with different conversion degrees 4 TiOF3 and TiO 2 composite nanomaterials. It is recorded as NTT-x (wherein x=0, 2, 5 hours) according to the different stirring time in the water bath. Disperse NTT-x in absolute ethanol, and exhaust the air with argon. Irradiate with a xenon lamp for 1 h, and keep bubbling argon gas during the process to keep the temperature of ethanol close...

Embodiment 2

[0035] Dissolve 0.5583g of ammonium hexafluorotitanate in 5ml of deionized water and 5ml of acetic acid, and add it dropwise to a mixture of 4ml of tetrabutyl titanate and 20ml of isopropanol during vigorous stirring. A small amount of gel was formed, and the mixture was stirred in an ice bath for 5 hours, transferred to a 50ml reaction kettle, and heated in water at 180°C for 5 hours. Cool to room temperature, wash with ethanol and deionized water, and dry under vacuum at 60 °C to obtain NH 4 TiOF 3 with TiO 2 The mixture is denoted as NTT. Disperse 0.5g of NTT into 80ml of 0.5mol / l boric acid solution, stir in a water bath at 40°C for 5 hours to obtain TiO 2 Nanomaterials are denoted as NTT-5. Disperse NTT-5 in absolute ethanol, and exhaust the air with argon. Irradiate with a xenon lamp for 1 h, and keep bubbling argon gas during the process to keep the temperature of ethanol close to the boiling point. The samples were taken out and dried at 80°C. This process is re...

Embodiment 3

[0037] Take 0.5583g of ammonium hexafluorotitanate and dissolve it in 1ml of deionized water and 4ml of acetic acid, add it dropwise to the mixture of 4ml of tetrabutyl titanate and 20ml of isopropanol during vigorous stirring, and continue stirring in an ice bath for 5h , transferred to a 50ml reactor, and heated at 180°C for 5h. Cool to room temperature, wash with ethanol and deionized water, and dry under vacuum at 60 °C to obtain NH 4 TiOF 3 with TiO 2 The mixture is denoted as NTT. Disperse 0.5g of NTT into 80ml of 0.5mol / l boric acid solution, stir in a water bath at 40°C for 5 hours to obtain TiO 2 Nanomaterials are denoted as NTT-5. Disperse NTT-5 in absolute ethanol, and exhaust the air with argon. Irradiate with a xenon lamp for 1 h, and keep bubbling argon gas during the process to keep the temperature of ethanol close to the boiling point. The samples were taken out and dried at 80°C. This process is repeated 4 times. The final sample is light yellow, which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com