Cationic waterborne polyurethane-chitosan blend and preparation method therefor

A water-based polyurethane and chitosan technology, applied in polyurea/polyurethane coatings, chitin polysaccharide coatings, coatings, etc., can solve the problems of increased cost, unstable blend structure, poor water resistance, etc., and achieve uniform blending. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0030]Add 0.005mol polytetrahydrofuran polyether glycol (PTMG2000) to a four-necked flask equipped with an electric stirrer, a thermometer and a reflux condenser, vacuum dehydrate and feed nitrogen, add 0.019mol isophorone diisocyanate (IPDI), and Hydrophilic chain extender 0.0096mol N-methyldiethanolamine (MDEA), then slowly warm up to 75°C, and react in an oil bath for 3h. Cool down to about 50°C and add 15g of acetone to dilute, add 0.0096mol glacial acetic acid to neutralize when the temperature is down to about 35°C, and react for half an hour. Under high-speed stirring, 37 g of deionized water was added dropwise with a constant pressure dropping funnel for emulsification, and finally acetone was removed by rotary evaporation to obtain a stable emulsion with a solid content of about 30%. The main chain of waterborne polyurethane is generally polymerized by oligomer polyols, diisocyanates and small molecule chain extenders. Oligomer polyol constitutes the soft segment of ...

example 2

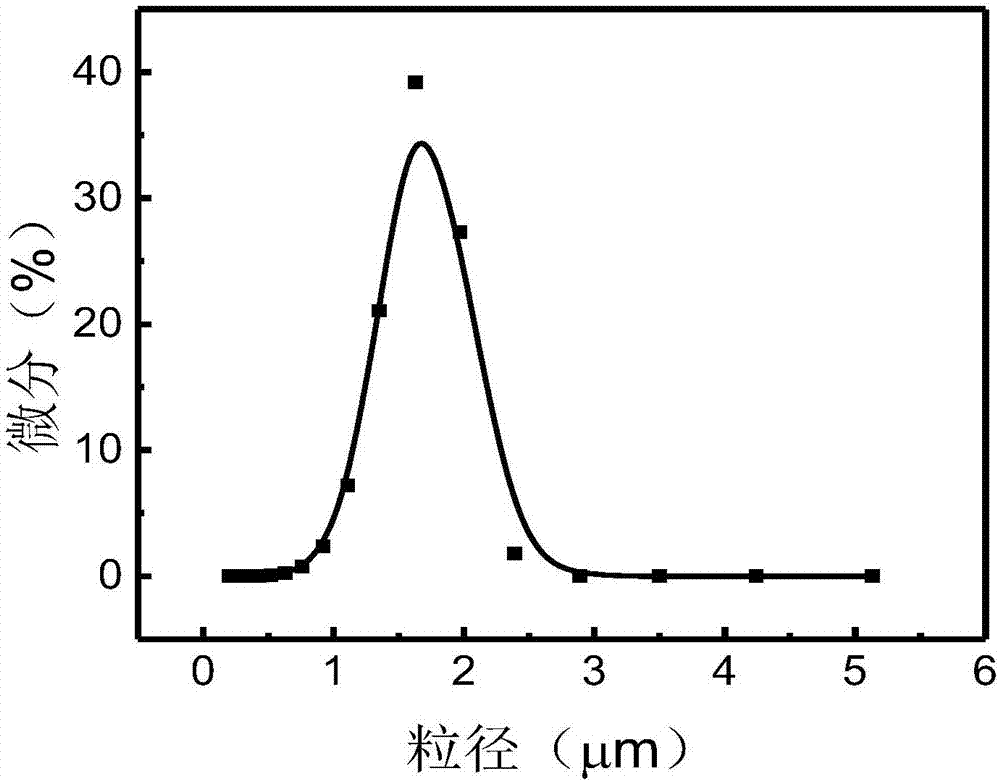

[0032] Add 0.005mol polytetrahydrofuran polyether glycol (PTMG2000) to a four-necked flask equipped with an electric stirrer, a thermometer and a reflux condenser, vacuum dehydrate and feed nitrogen, add 0.019mol isophorone diisocyanate (IPDI), and Hydrophilic chain extender 0.0096mol N-methyldiethanolamine (MDEA), then slowly warm up to 75°C, and react in an oil bath for 3h. Cool down to about 50°C and add 15g of acetone to dilute, add 0.0065mol glacial acetic acid to neutralize when the temperature is down to about 35°C, and react for half an hour. Chitosan (0.18g, molecular weight 50,000-100,000) was dissolved in dilute glacial acetic acid solution (37ml, mass fraction 0.5%, glacial acetic acid was 0.0031mol), and the above solution was dripped with constant pressure under high-speed stirring. The liquid funnel was added dropwise, and finally the acetone was removed by rotary evaporation to obtain a stable emulsion with a solid content of about 30%. Product has no crystall...

example 3

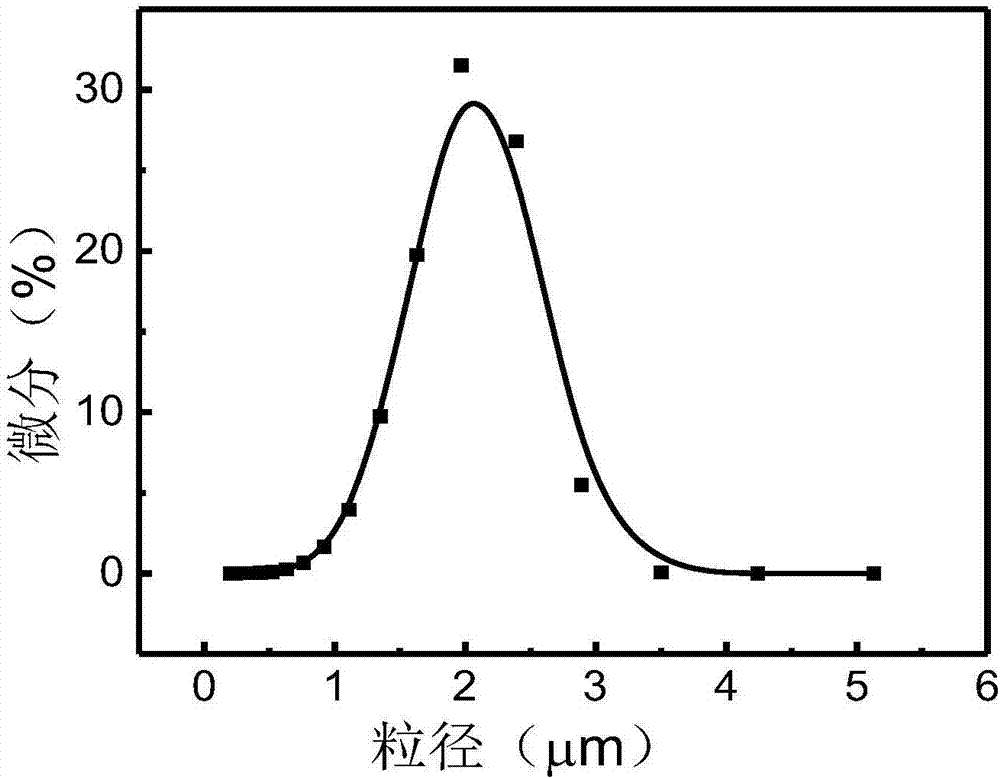

[0034] Add 0.005mol polytetrahydrofuran polyether glycol (PTMG2000) to a four-necked flask equipped with an electric stirrer, a thermometer and a reflux condenser, vacuum dehydrate and feed nitrogen, add 0.019mol isophorone diisocyanate (IPDI), and Hydrophilic chain extender 0.0096mol N-methyldiethanolamine (MDEA), then slowly warm up to 75°C, and react in an oil bath for 3h. Cool down to about 50°C, add 15g of acetone to dilute, and add 0.001mol of silane coupling agent KH550, and react for 1h. When the temperature is lowered to about 35°C, add 0.0065mol glacial acetic acid for neutralization, and react for half an hour. Chitosan (0.18g, molecular weight 50,000-100,000) was dissolved in dilute glacial acetic acid solution (37ml, mass fraction 0.5%, glacial acetic acid was 0.0031mol), and the above solution was dripped with constant pressure under high-speed stirring. The liquid funnel was added dropwise, and finally the acetone was removed by rotary evaporation to obtain a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com