Blended polymer coated high-nickel ternary positive electrode material and preparation method thereof

A technology of blending polymers and positive electrode materials, applied in the direction of positive electrodes, active material electrodes, electrical components, etc., can solve the problems of electrochemical performance deterioration, cycle performance weakening, electrical performance impact, etc. The effect of reducing the resistance of lithium/lithium intercalation and inhibiting dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

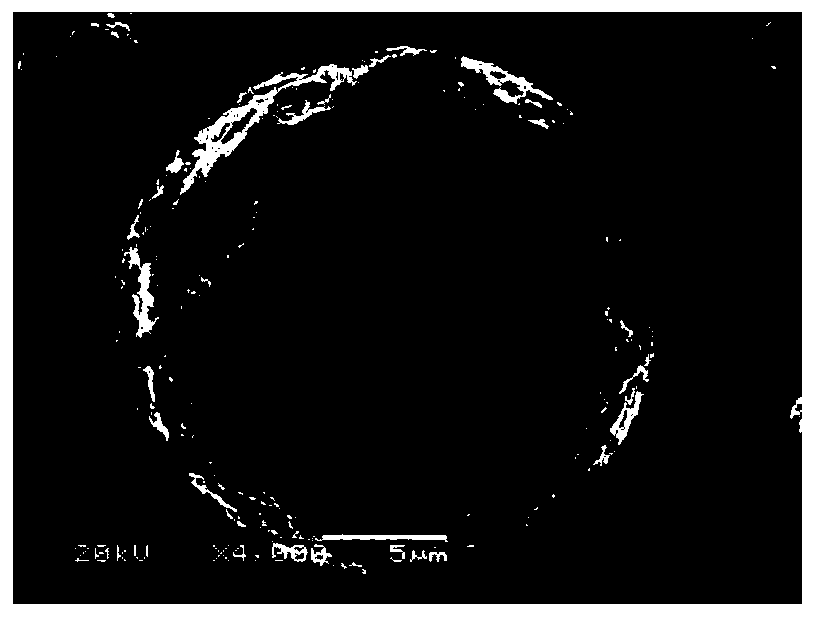

Image

Examples

Embodiment 1

[0033] Accurately weigh LiOH·H 2 Dissolve 11.50g of O, 25mL of acrylic acid, 25mL of aniline, and isopropanol (1 / 10,000th of the amount of monomer) in methanol so that the monomer concentration is about 15-20%, and stir in a water bath at 50°C until LiOH·H 2O is completely dissolved; dissolve 0.25g of azobisisobutyronitrile in methanol, 61.3g of ammonium persulfate in dilute hydrochloric acid, adjust the pH to between 3 and 4, and place them in constant pressure dropping funnels. Add the methanol solution of azobisisobutyronitrile dropwise within 30 minutes in a water bath at 75°C, and react for about 1 hour. After the white precipitate appears, add dilute hydrochloric acid solution of ammonium persulfate dropwise within 20 minutes, and continue the reaction for 2 to 5 hours. Evaporate methanol and water to dryness, wash with deionized water, absolute ethanol, and acetone in sequence until the filtrate is colorless, transparent and clear, filter with suction, and dry in vacuum...

Embodiment 2

[0036] Accurately weigh LiOH·H 2 Dissolve 5.75g of O, 12.5mL of acrylic acid, 12.5mL of pyrrole, and isopropanol (one ten-thousandth of the amount of monomer) in methanol so that the monomer concentration is about 15-20%, and stir in a water bath at 50°C until LiOH ·H 2 O is completely dissolved; dissolve 0.125g of azobisisobutyronitrile in methanol, and 22.34g of ammonium persulfate in dilute hydrochloric acid, adjust the pH to between 3 and 4, and place them in constant-pressure dropping funnels. Add the methanol solution of azobisisobutyronitrile dropwise within 30 minutes in a water bath at 75°C, and react for about 1 hour. After the white precipitate appears, add dilute hydrochloric acid solution of ammonium persulfate dropwise within 20 minutes, and continue the reaction for 2 to 5 hours. Evaporate methanol and water to dryness, wash with deionized water, absolute ethanol, and acetone in sequence until the filtrate is colorless, transparent and clear, filter with suctio...

Embodiment 3

[0039] Accurately weigh LiOH·H 2 O 11.50g, maleic acid 25mL, aniline 25mL, and isopropanol (1 / 10,000th of the amount of monomer) were dissolved in methanol so that the monomer concentration was around 15-20%, and stirred in a water bath at 50°C until LiOH·H 2 O is completely dissolved; dissolve 0.25g of azobisisobutyronitrile in methanol, 61.3g of ammonium persulfate in dilute hydrochloric acid, adjust the pH to between 3 and 4, and place them in constant pressure dropping funnels. Add the methanol solution of azobisisobutyronitrile dropwise within 30 minutes in a water bath at 75°C, and react for about 1 hour. After the white precipitate appears, add dilute hydrochloric acid solution of ammonium persulfate dropwise within 20 minutes, and continue the reaction for 2 to 5 hours. Evaporate methanol and water to dryness, wash with deionized water, absolute ethanol, and acetone in sequence until the filtrate is colorless, transparent and clear, filter with suction, and dry in vac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com