Bi2Ti2O7/Bi4Ti3O12 composite photocatalyst and preparation method thereof

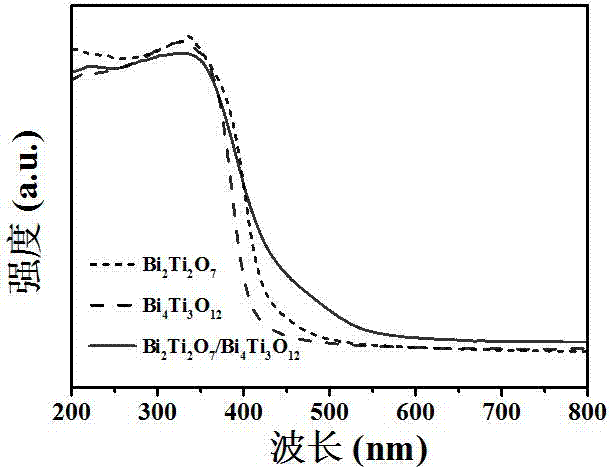

A catalyst and composite light technology, applied in the field of photocatalysis, can solve the problems of large particles of bismuth titanate-based mixed crystal material, high photo-generated electron-hole recombination rate, and difficulty in efficient utilization of visible light, etc. High absorption capacity, beneficial to industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 20 mL of glacial acetic acid solution to a 50 mL beaker, then add 0.8 g of bismuth nitrate, stir until dissolved, add 0.5 mL of acetylacetone and 0.5 mL of tetrabutyl titanate with a micro-injector, and mix the reactants evenly Afterwards, the solution was poured into an evaporating dish and evaporated at 180 °C for 10 h. The obtained powder was placed in a crucible and calcined at 650 °C for 2 h.

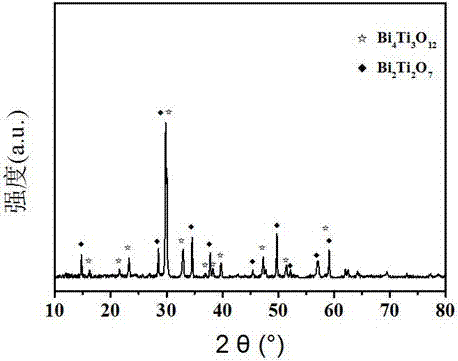

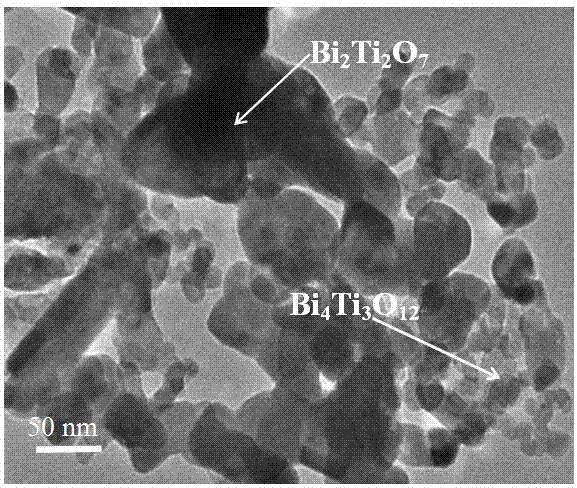

[0025] figure 1 For the XRD diffraction pattern of the prepared sample, the diffraction peaks in the figure are Bi 2 Ti 2 o 7 or Bi 4 Ti 3 o 12 Compared with the standard JCPDS card (32-0118, 21-1272), the characteristic diffraction peak can be identified as Bi with good crystallinity 2 Ti 2 o 7 / Bi 4 Ti 3 o 12 Powder, figure 2 It is the transmission electron micrograph of the prepared composite photocatalyst, the larger particle in the figure is Bi 4 Ti 3 o 12 Particles, smaller particles are Bi 2 Ti 2 o 7 , it can be seen from the figure that Bi 2 ...

Embodiment 2

[0028] Add 20 mL of glacial acetic acid solution to a 50 mL beaker, then add 0.6 g of bismuth nitrate, stir until dissolved by magnetic force, add 0.5 mL of acetylacetone and 0.5 mL of tetrabutyl titanate with a micro-injector, and mix the reactants evenly Afterwards, the solution was poured into an evaporating dish and evaporated at 140°C for 5 h. The obtained powder was placed in a crucible and calcined at 550 °C for 0.5 h.

Embodiment 3

[0030] Add 20 mL of glacial acetic acid solution to a 50 mL beaker, then add 0.8 g of bismuth nitrate, stir until dissolved, add 0.5 mL of acetylacetone and 0.5 mL of tetrabutyl titanate with a micro-injector, and mix the reactants evenly Afterwards, the solution was poured into an evaporating dish and evaporated at 140°C for 5h. The obtained powder was placed in a crucible and calcined at 600 °C for 1 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com