Preparation method and application of zinc oxide quantum dot-potassium niobate photocatalyst

A photocatalyst and quantum dot technology, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, carbon dioxide reduction method preparation, physical/chemical process catalyst, etc., can solve the problems of low visible light activity and reduced catalytic activity of the catalyst, Achieve the effects of simple operation, high yield, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

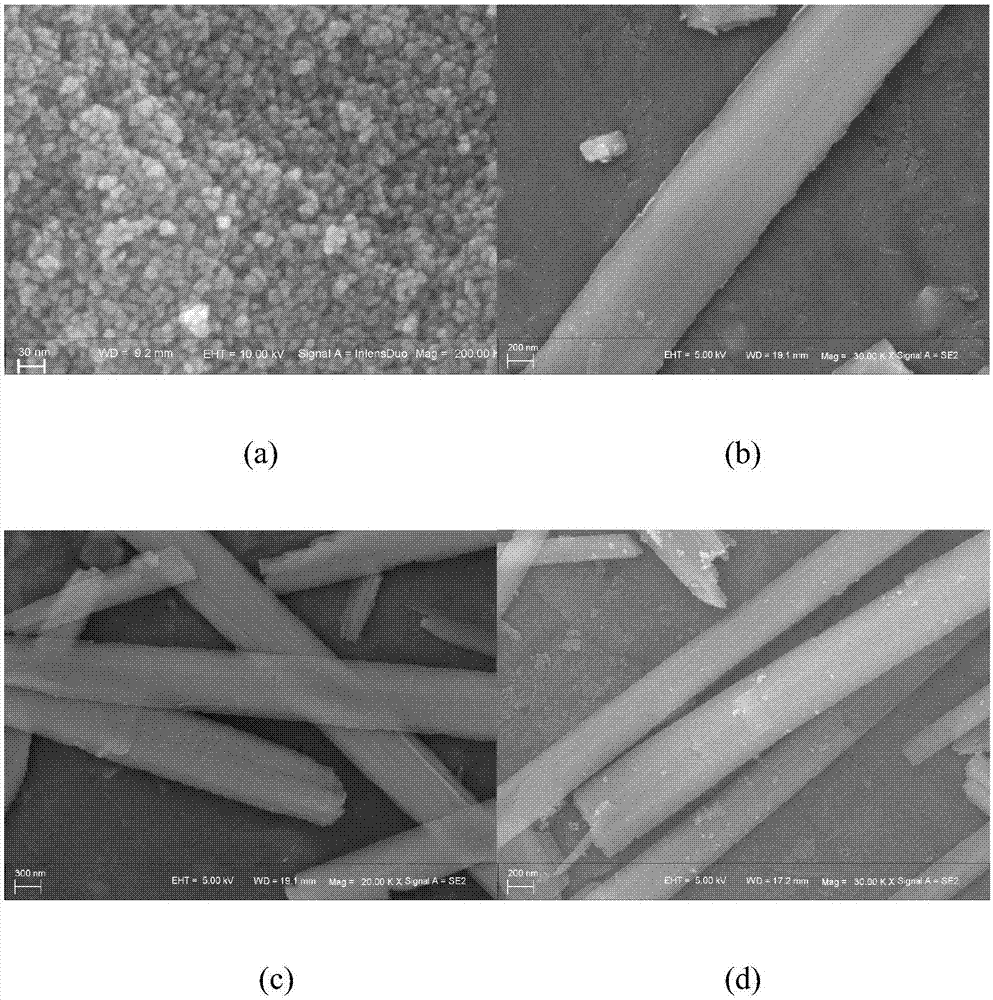

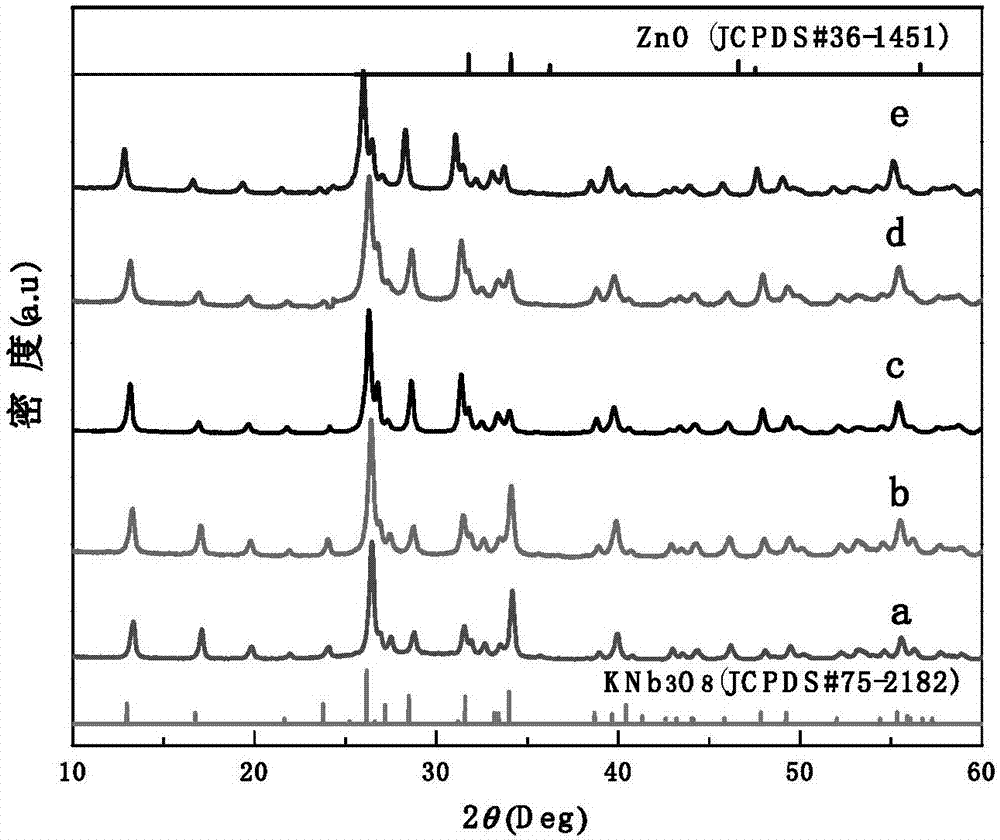

[0034] Zinc oxide quantum dots were synthesized by a solvothermal method, and the specific experimental steps were as follows:

[0035] (1) Weigh 1.387g (0.01mol) of zinc chloride and dissolve it in 100mL of triethylene glycol.

[0036] (2) Weigh 0.8g (0.02mol) of sodium hydroxide and dissolve it in 100mL of triethylene glycol.

[0037] (3) Put the above two solutions into an ultrasonic instrument and sonicate for 1 hour.

[0038] (4) Put the two sonicated solutions into a 250mL three-necked flask, heat the oil bath at 90°C for 3h under magnetic stirring at 500rpm, and then raise the temperature to 120°C for 1h.

[0039] (5), take out the well-reacted solution from the oil bath, after cooling to room temperature.

[0040] (6), wash with absolute ethanol and deionized water 3 times to obtain a pale yellow product.

[0041] (7) Put the product into an air blast drying oven at 80° C., and dry it at a constant temperature for 12 hours.

[0042] (8) Put the dried product into a...

Embodiment 2

[0044] Preparation of flaky KNb by secondary hydrothermal method 3 o 8 catalyst:

[0045] (1) Weigh 6.72g of potassium hydroxide (KOH) and dissolve it in 30mL of deionized water, and magnetically stir until it becomes a transparent and colorless solution.

[0046] (2), then weigh 0.442g of niobium pentoxide (Nb 2 o 5 ) was added to the above colorless solution, and magnetic stirring was continued for 30 min.

[0047] (3) Transfer the above white turbid liquid to a 75mL polytetrafluoroethylene reaction kettle, and conduct a hydrothermal reaction at 180°C for 48h.

[0048] (4) After the reaction is finished, take out the reactor and cool to room temperature to obtain a clear solution.

[0049] (5) Take the above solution into a 100mL beaker, put it into a constant temperature condensed water area at a constant temperature of 25°C, slowly add hydrochloric acid dropwise under magnetic stirring, and adjust the pH of the reaction system to 5-6.

[0050] (6) With the addition o...

Embodiment 3

[0056] Preparation of ZnO—KNb by hydrothermal method 3 o 8 catalyst:

[0057] (1) Weigh 6.72g of potassium hydroxide (KOH) and dissolve it in 30mL of deionized water, and magnetically stir until it becomes a transparent and colorless solution.

[0058](2), then weigh 0.442g of niobium pentoxide (Nb 2 o 5 ) was added to the above colorless solution, and magnetic stirring was continued for 30 min.

[0059] (3) Transfer the above white turbid liquid to a 75mL polytetrafluoroethylene reaction kettle, and conduct a hydrothermal reaction at 180°C for 48h.

[0060] (4) After the reaction is finished, take out the reactor and cool to room temperature to obtain a clear solution.

[0061] (5) Take the above solution into a 100mL beaker, put it into a constant temperature condensed water area at a constant temperature of 25°C, slowly add hydrochloric acid dropwise under magnetic stirring, and adjust the pH of the reaction system to 5-6.

[0062] (6) With the addition of hydrochlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com