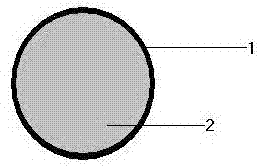

White-light infrared up-conversion composite luminescent material with core-shell structure

An infrared up-conversion and luminescent material technology, which is applied in the field of chemical new material preparation, and can solve the problem of inability to realize sensitive excitation and luminescence of invisible far-infrared lasers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh 2.282 g of hydrated cadmium chloride solid particles, place in a three-necked flask, add 500 ml of deionized water and stir for standby, then weigh 2.124 g of mercaptosuccinic acid, stir and dissolve for standby, and adjust the pH of the solution to 11 with NaOH after complete dissolution.

[0025] Separately take 0.254g of sodium borohydride and put it in a beaker, add 50ml of deionized water to dissolve it, and then add SeO 2 The particles were 0.223g, and the reaction was stirred for 30min.

[0026] Set the heating jacket temperature to 300 0 C, after constant temperature, add the solution in the beaker to the three-necked flask, pass nitrogen, add a condenser tube, and react at constant temperature for 3 hours. After the reaction is completed, close the heating mantle and cool to room temperature to obtain an aqueous quantum dot solution, and then take 50ml of the quantum dot solution, Add 50 ml of cyclohexanol solution, extract to obtain quantum dot solid part...

Embodiment 2

[0029] Weigh 4.602 g of hydrated cadmium chloride solid particles, place in a three-necked flask, add 200 ml of deionized water and stir for standby, then weigh 4.281 g of mercaptosuccinic acid, stir and dissolve for standby, and adjust the pH of the solution to 10 with NaOH after complete dissolution.

[0030] Another 0.567 g of sodium borohydride was placed in a beaker, 50 ml of deionized water was added to dissolve, and then 0.262 g of tellurium powder particles were added, and the reaction was stirred for 30 min.

[0031] Set the heating jacket temperature to 300 0 C, after constant temperature, add the solution in the beaker to the three-necked flask, pass nitrogen, add a condenser, and react at constant temperature for 3 hours. After the reaction is completed, close the heating mantle and cool to room temperature to obtain an aqueous quantum dot solution, and then take 20ml of the quantum dot solution, Add 100 ml of isopropanol solution, extract to obtain quantum dot sol...

Embodiment 3

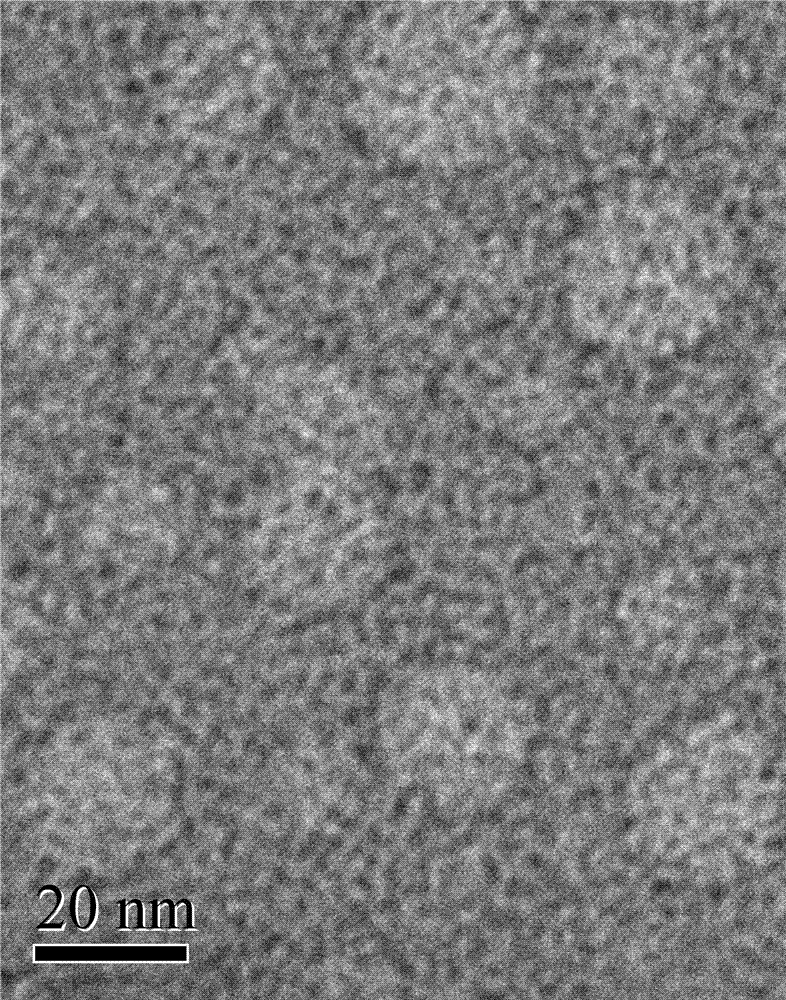

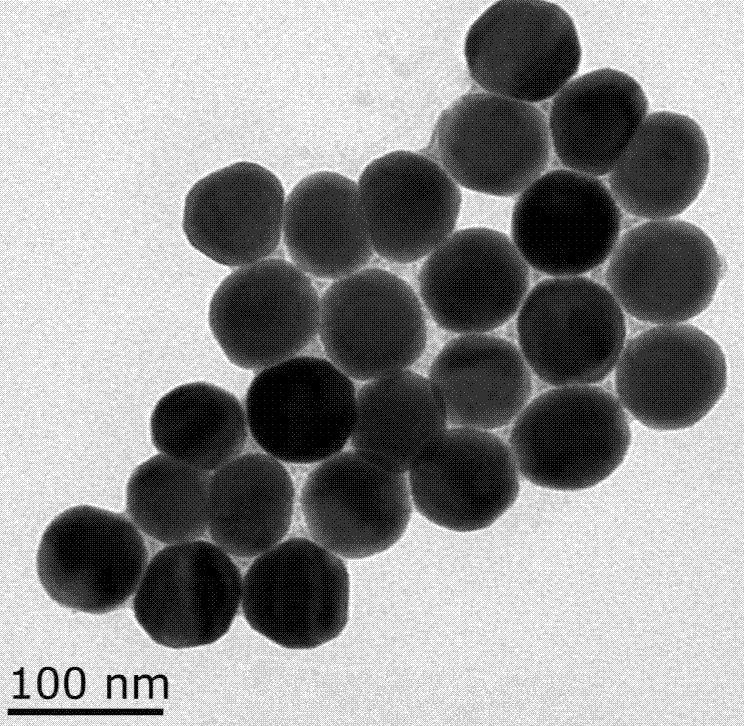

[0034] Preparation of blue-emitting infrared upconversion nanomaterials: take YF 3 90g, GdF 3 10g, add YbF 3 45g, TmF 3 13g at 400 under argon 0 C was sintered for 2 hours, and the prepared infrared up-conversion fluorescent material was excited by laser at 980 nm, and could emit blue light at 450 nm, and the particles were at 100 nm.

[0035] Take out 30g of the above infrared up-conversion fluorescent material and add it to the three-necked flask, then add 100ml of ethylene glycol, stir and disperse evenly, and then add 0.5g of 3-aminopropyltrimethoxysilane as the surface silanization material, under the protection of nitrogen at 60 0 The reaction was stirred at a constant temperature for 10 hours. After the reaction was completed, it was washed with anhydrous ethanol until neutral, and then diluted to 100ml with deionized water. Then 0.2g of glutaraldehyde was added as the surface aldehyde-based material, and the nitrogen was protected. The reaction was stirred at low t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ll | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com