Soybean protein polypeptide and applications thereof

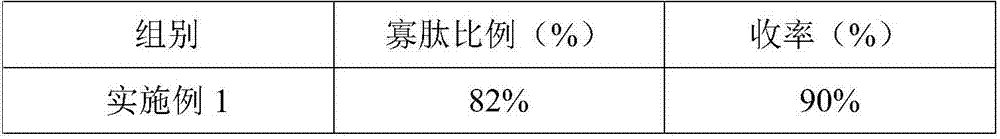

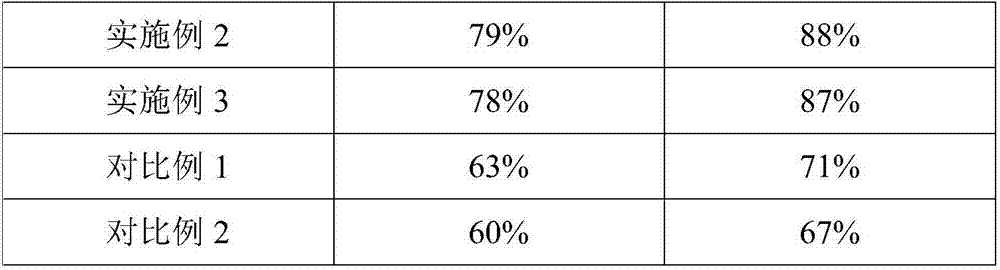

A technology of soy protein and polypeptide wine, which is applied in the field of soy protein, can solve the problems of low yield of soy protein polypeptide, low purity of soy protein polypeptide, complex and cumbersome process, etc., achieve high polypeptide yield, improve human immunity, and promote blood circulation. loop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

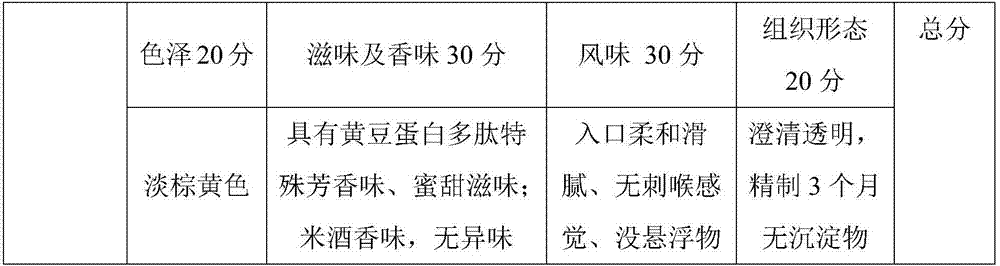

Examples

preparation example Construction

[0040] A soybean protein polypeptide. The preparation method of soybean protein polypeptide includes:

[0041] Alkali dissolving step: take soybean powder, add purified water to prepare a slurry, adjust the pH of the slurry to 8-9, then place it in a microwave extraction device and heat for 12-18min, control the temperature at 52-58℃, turn off the microwave and keep warm 0.8-1.2h, filter, take the filtrate to obtain protein liquid;

[0042] The first enzymolysis step: lower the temperature of the protein solution to room temperature, adjust the pH to 7-8, then add the first protease, stir well to obtain the first mixed solution; then place the first mixed solution in the microwave extraction device Medium heating for 12-18min, control the temperature at 52-58℃, and keep the pH value of the first mixed solution above 6.5 to obtain the first enzymolysis solution;

[0043] The second enzymolysis step: lower the temperature of the first enzymolysis solution to room temperature, adjust t...

Embodiment 1

[0070] A soy protein polypeptide wine prepared according to the following method:

[0071] A. Preparation of soybean protein peptide

[0072] Alkali dissolving step: take the soybean powder with a particle size of 230-400 mesh, add purified water according to the solid-liquid ratio of 1:15 to prepare a slurry, and add 2% of the mass of soybean powder xanthan gum, and then adjust the pH of the slurry with NaOH solution To 8.5, then place it in a microwave extraction device with a frequency of 2500MHz and a power of 20KW and heat it for 15 minutes to bring the temperature to 55°C, turn off the microwave and keep it warm for 1 hour, filter, and take the filtrate to obtain a protein solution;

[0073] The first enzymolysis step: lower the temperature of the protein solution to room temperature, adjust the pH to 7.5, and then add serine protease and pectinase. The addition amount of serine protease and pectinase are respectively 3% and 3% of the protein content in the protein solution. 1...

Embodiment 2

[0084] The difference between Embodiment 2 and Embodiment 1 is:

[0085] Alkali dissolving step: take the soybean powder with a particle size of 230-400 mesh, add purified water according to the solid-liquid ratio of 1:12 to prepare a slurry, and add locust bean gum of 5% by mass of the soybean powder, followed by Na 2 CO 3 The solution adjusts the pH value of the slurry to 8, and then places it in a microwave extraction device with a frequency of 2450MHz and a power of 19KW and heats it for 18 minutes to bring the temperature to 52°C, turn off the microwave and keep it for 1.2h, filter, and take the filtrate to obtain a protein solution;

[0086] The first enzymolysis step: lower the temperature of the protein solution to room temperature, adjust the pH to 8, and then add serine protease and pectinase. The added amount of serine protease and pectinase is 2% of the protein content in the protein solution. Stir thoroughly to obtain the first mixed liquid; then place the first mixed l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com