Nickel-and-molybdenum based bimetallic carbide loaded on nickel foam and preparation method and application thereof

A bimetallic carbide and nickel foam technology, which is applied in metal material coating technology, liquid chemical plating, electrodes, etc., can solve the problems of unachievable promotion, low storage content, increased energy consumption, etc., and achieve easy application and high purity High, mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

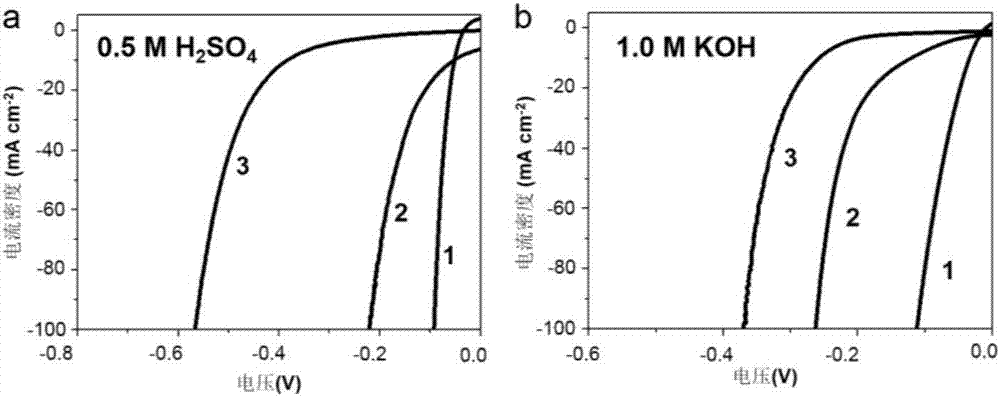

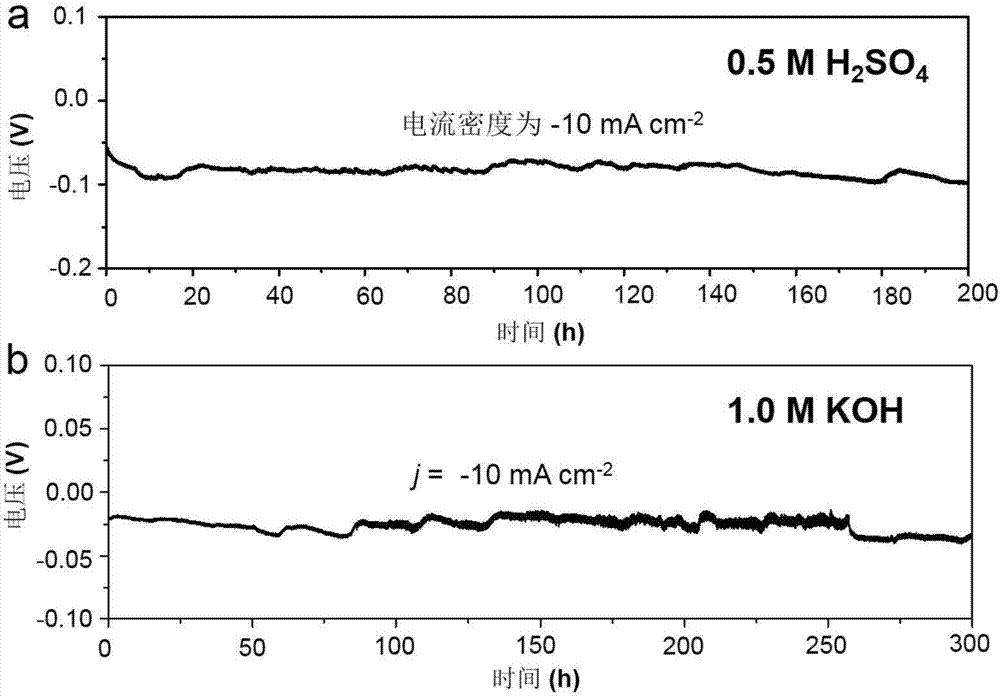

[0033] Step 1. Preparation of nickel-molybdenum-based bimetallic carbide supported on nickel foam

[0034] 0.4362g Ni(NO 3 ) 2 6H 2 O, 0.5191g (NH 4 ) 6 Mo 7 o 24 4H 2O and 0.1g of glucose were added to 30mL of deionized water, and dispersed evenly by ultrasonication for 30 minutes. React in an oven for 6 hours, and after naturally cooling to room temperature, take out the nickel foam, wash it with deionized water, and dry it in an oven at 60°C. The dried nickel foam is loaded into the quartz ark; the quartz ark is pushed into the central hot zone of the tube furnace, and the flange is sealed; the hydrogen and argon are measured by the rotameter (the hydrogen flow rate is 0.015L min -1 , the argon gas flow rate is 0.085L min -1 ) into the tube furnace after being fully mixed; at 5°C min -1 Raise the temperature of the tube furnace to 700°C at a rate of 120 minutes, and then cool it down to room temperature naturally, take out the quartz ark, and obtain the nickel-mo...

Embodiment 2

[0049] 0.4362g Ni(NO 3 ) 2 6H 2 O, 0.5191g (NH 4 ) 6 Mo 7 o 24 4H 2 O and 0.1g were dispersed in glucose and added to 30mL deionized water, and the ultrasonic wave was dispersed evenly for 30 minutes. ℃ oven for 6 hours, after naturally cooling to room temperature, the nickel foam was taken out, washed with deionized water, and dried in an oven at 60℃. The dried nickel foam is loaded into the quartz ark; the quartz ark is pushed into the central hot zone of the tube furnace, and the flange is sealed; the hydrogen and argon are measured by the rotameter (the hydrogen flow rate is 0.015L min -1 , Argon gas flow rate is 0.085Lmin -1 ) into the tube furnace after being fully mixed; at 5°C min -1 Raise the temperature of the tube furnace to 500°C at a constant temperature for 120 minutes; then cool down to room temperature naturally, take out the quartz ark, and obtain nickel-molybdenum-based bimetallic carbide supported on nickel foam. Features and properties are simila...

Embodiment 3

[0051] 0.4362g Ni(NO 3 ) 2 6H 2 O, 0.5191g (NH 4 ) 6 Mo 7 o 24 4H 2 O and 0.1g were dispersed in glucose and added to 30mL deionized water, and the ultrasonic wave was dispersed evenly for 30 minutes. ℃ oven for 6 hours, after naturally cooling to room temperature, the nickel foam was taken out, washed with deionized water, and dried in an oven at 60℃. The dried nickel foam is loaded into the quartz ark; the quartz ark is pushed into the central hot zone of the tube furnace, and the flange is sealed; the hydrogen and argon are measured by the rotameter (the hydrogen flow rate is 0.015L min -1 , the argon gas flow rate is 0.085L min -1 ) into the tube furnace after being fully mixed; at 5°C min -1 Raise the temperature of the tube furnace to 900°C at a constant temperature for 120 minutes; then cool down to room temperature naturally, take out the quartz ark, and obtain nickel-molybdenum-based bimetallic carbide supported on nickel foam. Features and properties are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com