Formaldehyde-sensitive material CdGa2O4 with ultrahigh sensitivity and selectivity and preparation method thereof

A sensitive material and sensitive technology, applied in material resistance, material analysis, material analysis by electromagnetic means, etc., can solve the problems of high sensitivity and selective detection that have not yet been recognized, and achieve efficient formaldehyde molecular adsorption and diffusion channels, Increase the effect of adsorption and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

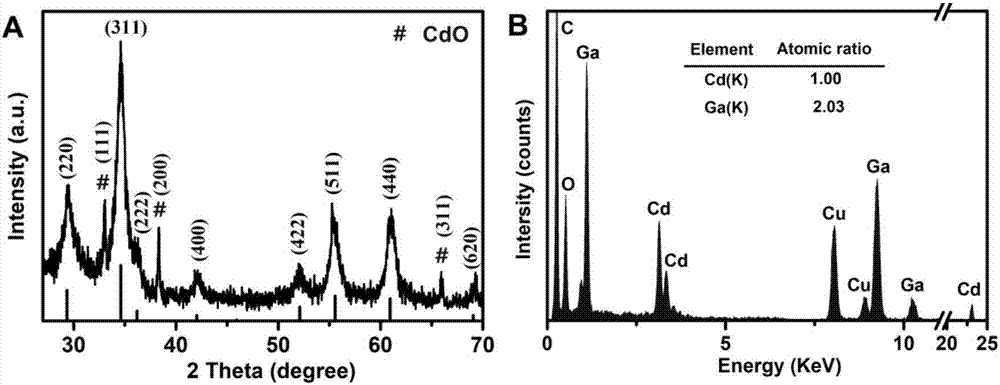

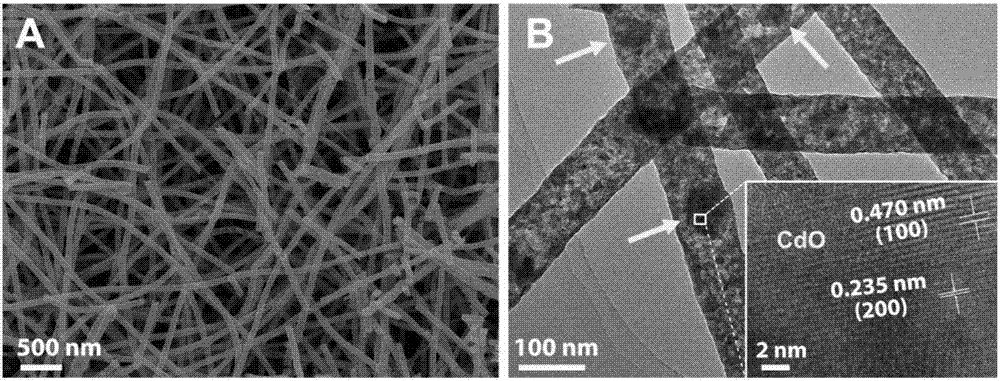

[0023] Example 1: CdGa 2 o 4 Preparation of Porous Nanofibrous Materials

[0024] 0.063g Cd(NO 3 ) 2 4H 2 O (0.206mmol) and 0.172g Ga (NO 3 ) 3 9H 2 O (0.412mmol) was sequentially added to 6.6g ethanol and 2.2g DMF mixed solvent, stirred at room temperature until completely dissolved, and it was a colorless transparent solution. Under stirring, 0.8 g of polyvinylpyrrolidone (PVP) was added, and stirred at room temperature for 12 hours to obtain a uniform solution. Pour the solution into a 5mL syringe, the inner diameter of the needle is 0.41mm, and the aluminum foil is used as the cathode receiving plate to collect the nanofiber product. The distance between the aluminum foil and the two pole plates of the needle is 20cm, the applied voltage is 22kV, the temperature is 25°C, and the humidity is 20%. , followed by electrospinning, and nanofiber precursors were obtained on the receiving plate after 24 h. The nanofiber precursor was dried at 70°C for 24h, and the obtaine...

Embodiment 2

[0026] Example 2: CdGa 2 o 4 Manufacture of material gas sensor

[0027] The main body of the gas sensor is a corundum ceramic tube with a diameter of 1mm and a length of 4mm. There are Au electrodes on both sides of the outer surface of the ceramic tube, and two platinum wires are connected to each Au electrode as a wire. The die is a nickel-chromium alloy heating wire, which is used to heat the device to provide operating temperature. The manufacture method of the gas sensor is as follows: (1) take an appropriate amount of CdGa 2 o 4 Sensitive materials are placed in a clean agate mortar, a small amount of ethanol is added dropwise and then vigorously ground for 5 minutes to prepare a thick slurry. (2) Apply the above-mentioned slurry evenly on the outer surface of the corundum ceramic tube with a sensitive brush, and completely cover the gold electrode, and dry it at room temperature for later use; CdGa 2 o 4 The thickness of the sensitive film is about 0.1mm. (3) In...

Embodiment 3

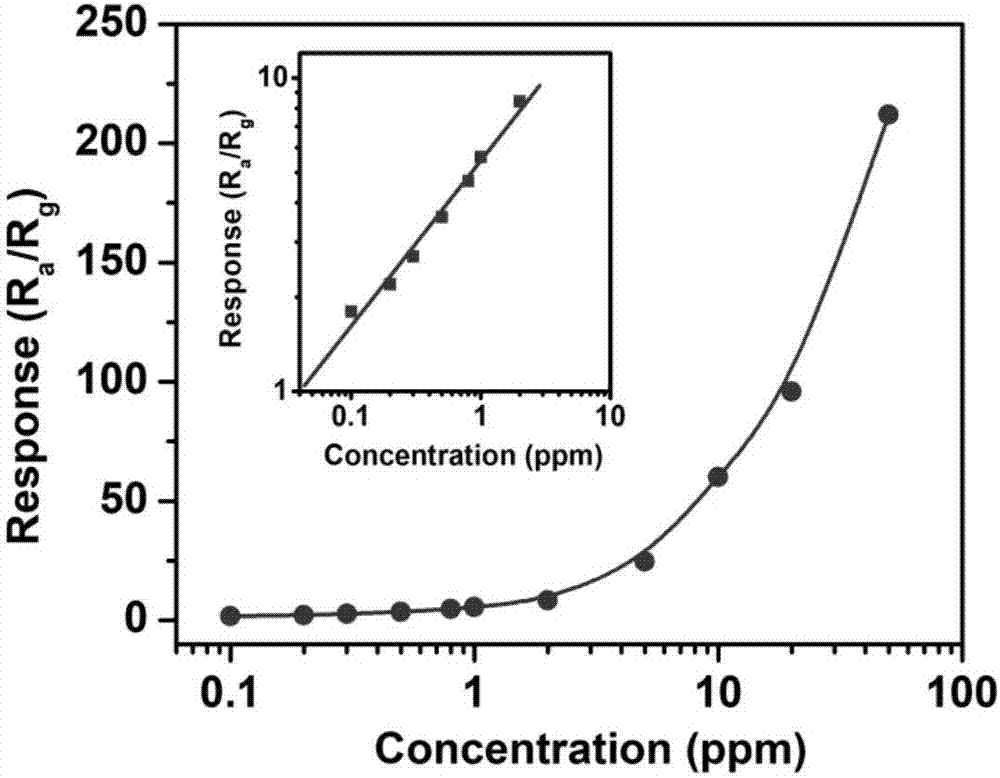

[0028] Example 3: CdGa 2 o 4 Gas Sensitive Properties Test of Gas Sensors

[0029] The gas-sensing property of the material is evaluated by making the material into a gas-sensing device with a CGS-8 intelligent gas-sensing analysis system (Beijing Elite Technology Co., Ltd.). The system is a static analysis system consisting of three parts: gas box, gas box base and main engine. The actual test is carried out with a self-provided 2.5-liter gas cylinder. First, under the experimental environmental conditions (relative humidity 20%, room temperature 20°C), the device has a resistance after it reaches stability in the air, which is denoted as R a , and then use a syringe or a micro-sampler to measure a certain amount of the gas to be tested and inject it into the test gas cylinder. After a certain period of time, after the gas is completely mixed, put the device into the test bottle. At this time, the resistance of the device will vary due to the material The interaction with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com