Growth method of large-sized silicon carbide polycrystalline ceramic adjustable in electrical resistivity

A technology of polycrystalline ceramics and growth methods, applied in the directions of polycrystalline material growth, single crystal growth, single crystal growth, etc. The high cost of silicon production can achieve the effect of avoiding polycrystalline cracking, good density, and improving quality and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

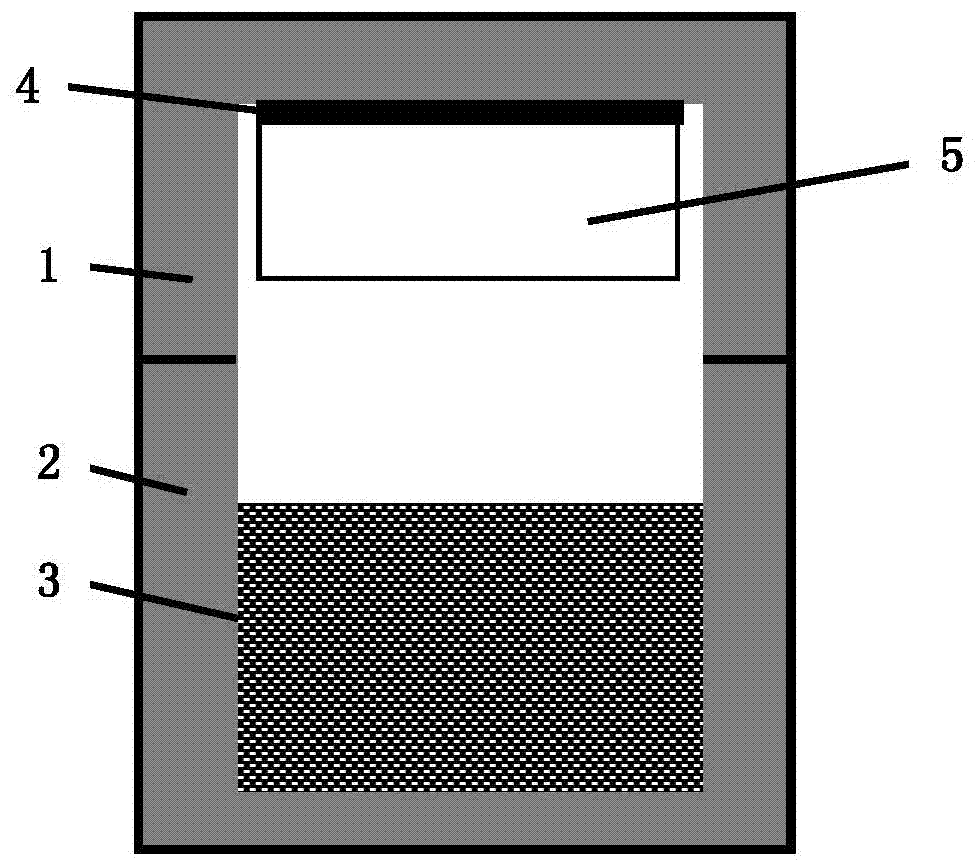

[0042] First, the graphite cover (graphite crucible top cover) coated with a carbon film layer on the top, and the graphite crucible with silicon carbide raw material (purity 99.9%) in the bottom material area are placed in the insulating carbon felt, and then put into the crystal growth furnace chamber ( The silicon carbide raw material is placed in the high temperature zone of the graphite crucible body, and the top cover of the graphite crucible with the carbon film coated on the inner surface of the growth is placed in the low temperature zone. The temperature gradient from the top cover of the graphite crucible to the bottom of the graphite crucible body is 2°C / cm. ), vacuum to 1.0×10 -2 Below Pa, fill with argon until the growth pressure is 20 Torr, and at the same time, the nitrogen flow rate is 1 sccm during the growth process, start to heat up to the growth temperature of 2080°C, after 100 hours of growth, cool down to room temperature, and open the furnace to obtain c...

Embodiment 2

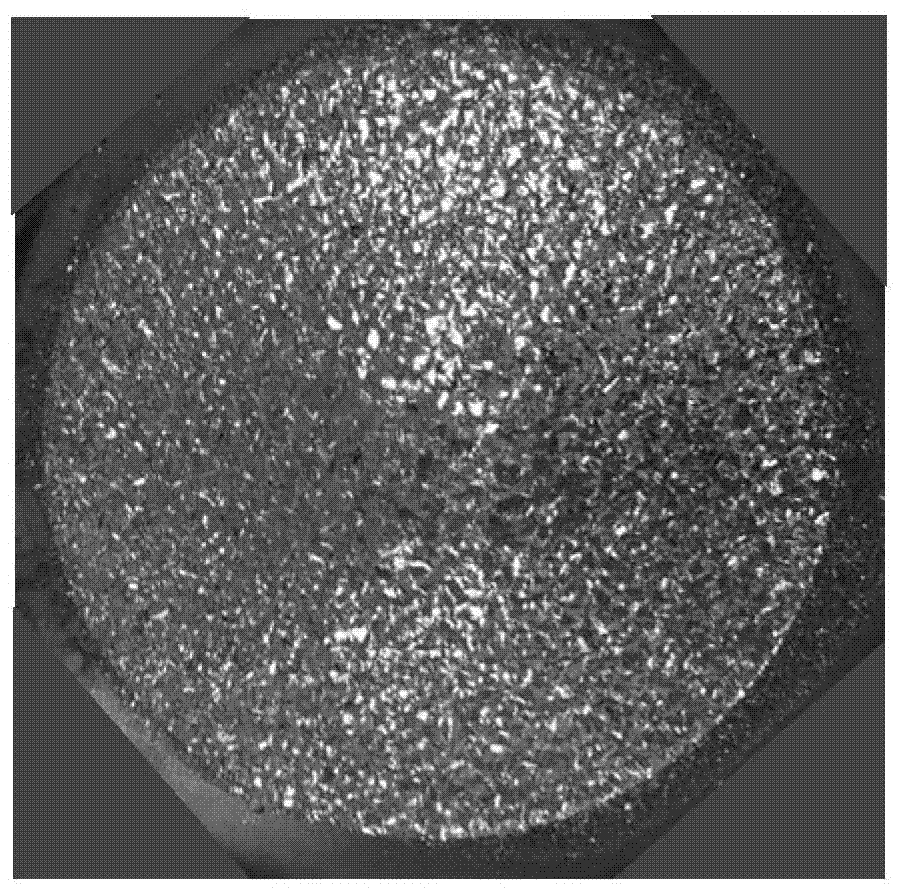

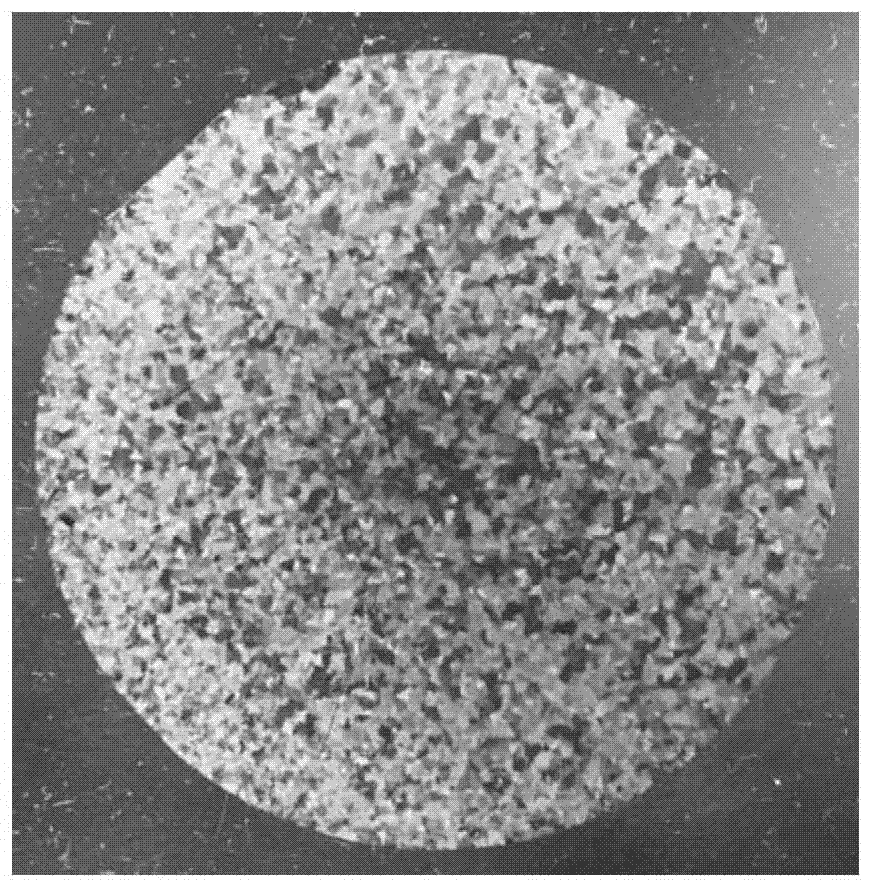

[0044] First, the graphite cover coated with a carbon film layer on the top, and the graphite crucible with silicon carbide raw material (99.9% purity) in the bottom material area are placed in the thermal insulation carbon felt, and then put into the crystal growth furnace chamber (the silicon carbide raw material is placed in In the high-temperature zone of the graphite crucible body, place the top cover of the graphite crucible coated with carbon film on the inner surface of the growth in the low-temperature zone. ×10 -2 Below Pa, fill with argon gas to a growth pressure of 10 Torr, start to heat up to a growth temperature of 2120°C, and after 100 hours of growth, cool down to room temperature with a program, and open the furnace to obtain a silicon carbide polycrystalline ceramic material with a thickness of 20 mm on a graphite cover (such as Figure 4 shown), and finally obtain silicon carbide polycrystalline ceramic sheets by mechanical processing (such as Figure 5 sho...

Embodiment 3

[0046] First, the graphite cover coated with a carbon film layer on the upper part and the graphite crucible with silicon carbide raw material (purity 99.99%) in the bottom material area are placed in the thermal insulation carbon felt, and then put into the crystal growth furnace chamber (the silicon carbide raw material is placed in In the high-temperature zone of the graphite crucible body, place the top cover of the graphite crucible coated with carbon film on the inner surface of the growth in the low-temperature zone. ×10 -2 Below Pa, fill with argon gas to a growth pressure of 10Torr, start to heat up to a growth temperature of 2120°C, after 100 hours of growth, program cooling to room temperature, open the furnace to obtain a silicon carbide polycrystalline ceramic material with a thickness of 20mm on the graphite cover, and finally through the mechanical process. Processed silicon carbide polycrystalline ceramic sheet (thickness 1mm, diameter 125mm), the measured resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com