Composite positive electrode material and preparation method thereof

A composite positive electrode material and positive electrode technology, which is applied in the direction of battery electrodes, electrical components, electrochemical generators, etc., can solve the problems that affect the electrochemical performance and safety performance of positive electrode materials, low initial charge and discharge efficiency of batteries, strong oxidation of electrolyte, etc. problems, to achieve the effect of improving the overall electrochemical performance, improving the first charge and discharge efficiency, and improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a method for preparing a composite positive electrode material, comprising the following steps:

[0023] Step 1: dissolving a certain amount of aluminum salt in a solvent to obtain an aluminum salt solution, adding a certain amount of positive electrode matrix material to the aluminum salt solution, and uniformly dispersing to obtain a primary mixed solution;

[0024] Step 2: dissolving a certain amount of fluoride salt and phosphate in a solvent to prepare a mixed solution of fluoride salt and phosphate;

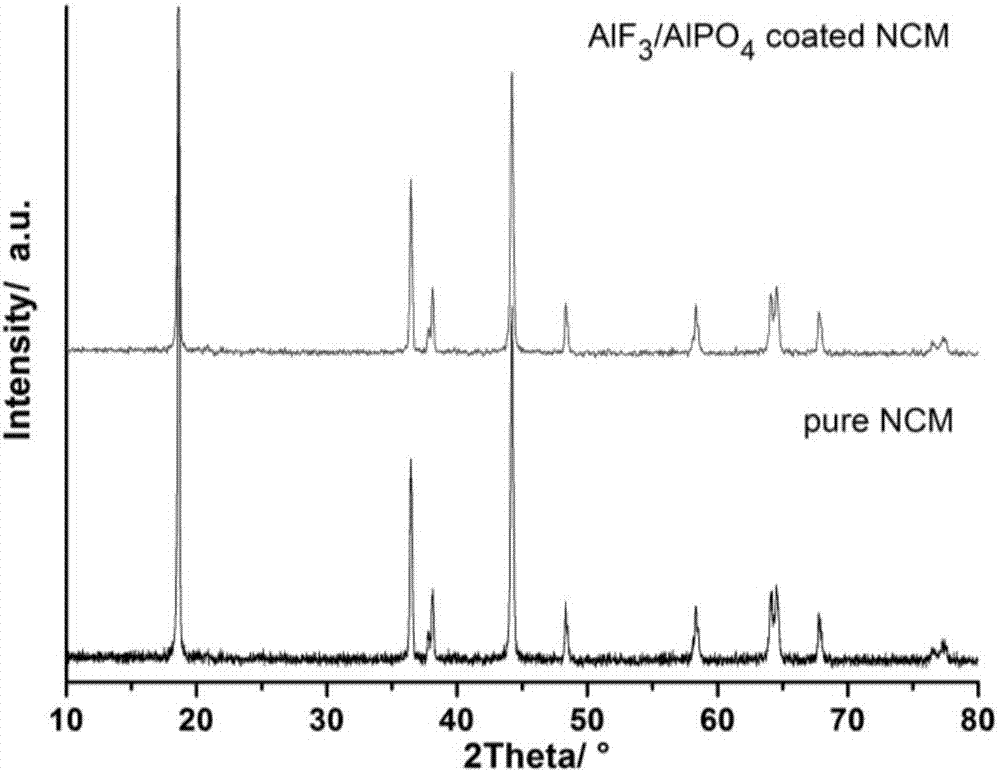

[0025] Step 3: In the case of continuous stirring, add the mixed solution of fluoride salt and phosphate salt prepared in Step 2 dropwise to the primary mixed solution prepared in Step 1, let stand after a period of reaction, wash, filter and dry , sintered in an inert atmosphere, that is, a composite positive electrode material coated with a composite coating layer is obtained; the composite coating layer includes AlF 3 and AlPO 4 , the mass...

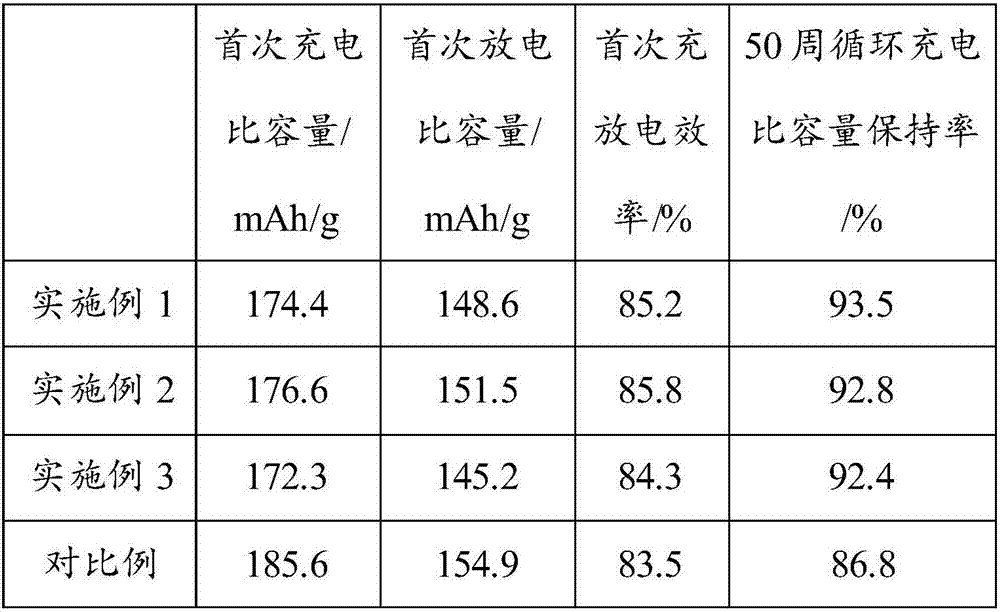

Embodiment 1

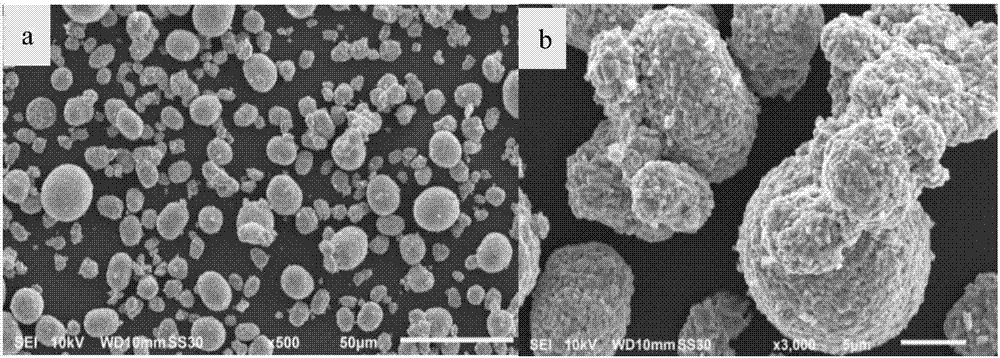

[0030] Weigh 1.39g of Al(NO 3 ) 3 9H 2 O was dissolved in 100mL deionized water to prepare an aluminum nitrate solution, and 10.0g of LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Add it into the aluminum nitrate solution, stir and disperse to obtain a primary mixed solution; weigh 0.31g of NH 4 F and 0.12g of (NH 4 ) 2 HPO 4 Dissolve in 20mL deionized water to prepare a mixed solution of fluoride salt and phosphate; under the condition of continuous stirring, add the prepared fluoride salt solution and phosphate solution dropwise into the primary mixed solution, react for 2 hours and then let it stand , after cleaning, filtering and drying, sintering at 400°C for 5h in an inert atmosphere, to obtain AlF-coated 3 / AlPO 4 A composite positive electrode material with a composite cladding layer.

Embodiment 2

[0032] Weigh 1.01g of Al 2 (SO 4 ) 3 Dissolve in 100mL deionized water to prepare aluminum sulfate solution, weigh 10.0g of LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Add it into the aluminum sulfate solution, stir and disperse to obtain a primary mixed solution; weigh 0.20g of NH 4 F and 0.16g of (NH 4 ) 2 HPO 4 Dissolve in 20mL deionized water to prepare a mixed solution of fluoride salt and phosphate; under the condition of continuous stirring, add the prepared fluoride salt solution and phosphate solution dropwise into the primary mixed solution, react for 3 hours and then let it stand , after cleaning, filtering and drying, sintering at 500°C for 4h in an inert atmosphere to obtain AlF-coated 3 / AlPO 4 A composite positive electrode material with a composite cladding layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com