Method for promoting electrolysis of sludge microorganisms for hydrogen production by joint use of ultrasound and alkali

A microbial electrolysis and ultrasonic technology, applied in the electrolysis process, electrolysis components, biochemical fuel cells, etc., can solve the problems of only 25% to 60%, long period of sludge anaerobic digestion, and low gas production rate and gas production rate. , to achieve the effect of less investment in equipment and equipment, wide applicability and improved utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] SS 7.61g / L, VSS 4.86g / L, TCOD 8954mg / L, SCOD 46mg / L, protein 2mg / L, total sugar 2mg / L, nucleic acid 3mg / L, ammonia nitrogen 79mg / L in the residual sludge of a sewage treatment plant , pH 7.3, γ1.04mS / cm.

[0059] After adding 1 mol / L NaOH to adjust the pH of the remaining sludge to 11, ultrasonic irradiation was performed, and ultrasonic reaction was performed for 30 minutes at a sound energy density of 1.5 W / mL to obtain sludge after ultrasonic and alkali treatment.

[0060] The SS of treated sludge is 6.58g / L, VSS 3.07g / L, TCOD 8638mg / L, SCOD 1039mg / L, protein 175mg / L, total sugar 82mg / L, nucleic acid 64mg / L, amino acid 58mg / L, ammonia nitrogen 112mg / L, pH 7.2, γ5.34mS / cm.

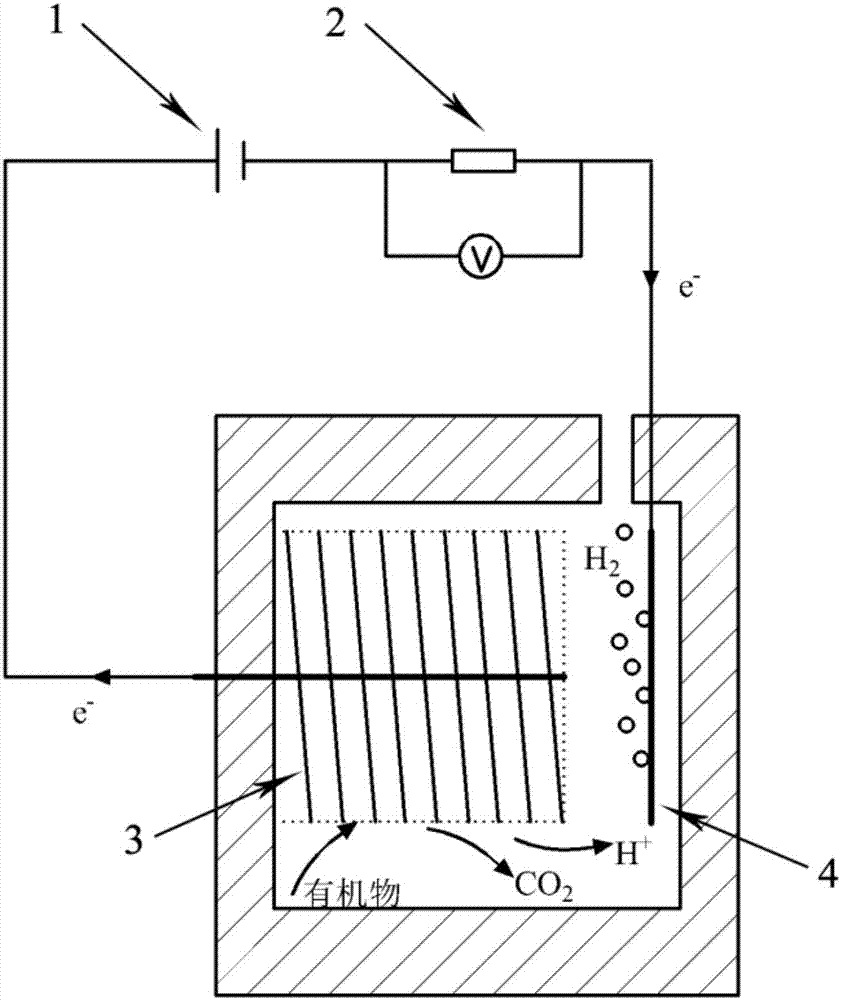

[0061] A single-chamber MEC was run with pretreated sludge as substrate.

[0062] Connect resistors in series between the two poles of the MEC reactor and apply an external voltage of 0.9V. At room temperature (19-25°C), the SS removal rate is 35.5%, the VSS removal rate is 45.8%, the TCOD remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com